Snapper E9266 User Manual

Page 13

13

Section 3 - MAINTENANCE

3.1 INTRODUCTION

To retain the quality of the snow thrower, use only

genuine SNAPPER replacement parts. Contact a

local SNAPPER dealer for parts and service

assistance. For the correct part or information for a

particular snow thrower, always mention model and

serial number.

3.2 SERVICE - AFTER FIRST 5 HOURS

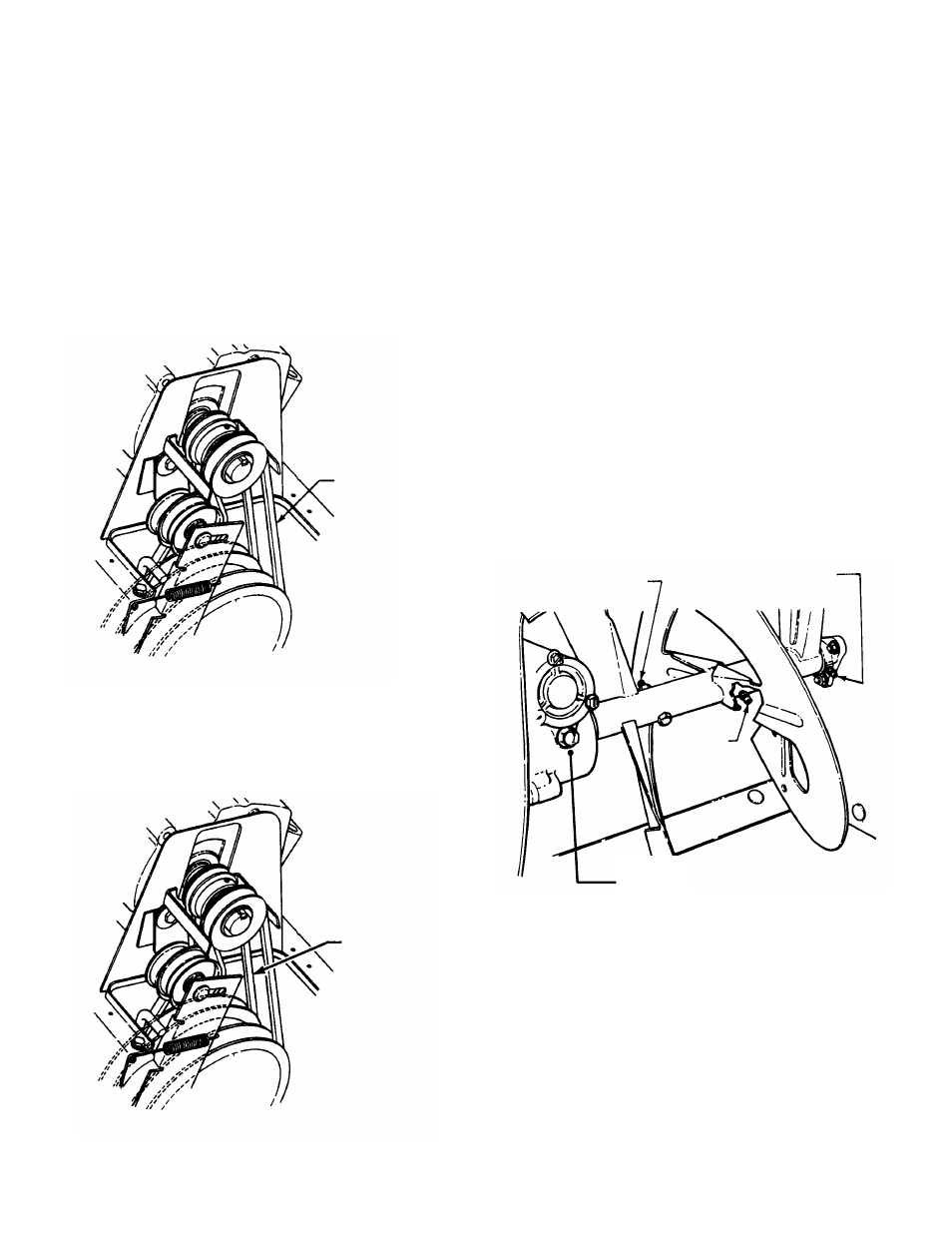

3.2.1 CHECK AUGER DRIVE BELT

1. Visually check engine drive belt for cracking,

fraying, severed or belt strands exposed. Replace

belt before operating snow thrower. See Figure 3.1

FIGURE 3.1

3.2.2 CHECK WHEEL DRIVE BELT

1. Visually check wheel drive belt for cracking,

fraying, severed or belt strands exposed. Replace

belt before operating snow thrower. See Figure 3.2.

FIGURE 3.2

3.3 GENERAL

LUBRICATION

Lubricate machine as instructed before and after

operation each season.

3.3.1. GEAR CASE, AUGER SHAFT and AUGER

BEARING LUBRICATION

1. Before each season of operation, apply two

shots of grease from a grease gun into gear case.

Use Benelene 900 or equivalent grease. The

grease plug for the gear case is located in front of

the gear case. See Figure 3.3.

2. Before each season of operation, apply two

shots of from a grease gun into auger bearing. Use

Benelene 900 or equivalent grease. The grease

fitting for the auger bearing is located on each end

of the auger. See Figure 3.3.

3. Before each season of operation, apply two

shots of general purpose grease from a grease gun

into the auger shaft. The grease fitting for the auger

shaft is located in the middle of each auger.

Remove shear bolts and rotate auger to distribute

grease evenly around shaft. Reinstall shear bolts

and nuts. Tighten to 5 to 10 ft. lb. of torque. See

Figure 3.3.

FIGURE 3.3

3.3.2. GENERAL LUBRICATION

After each season of operation, spread a small

amount of grease on: The axle shafts for easy

wheel removal. The discharge chute and mounting

flange retainers for smooth rotation.

AUGER BELT

WHEEL DRIVE

BELT

SHEAR BOLT

BEARING GREASE

FITTING

GREASE

FITTING

GREASE

PLUG