Warning – Snapper E9266 User Manual

Page 15

15

Section 4 - REPAIR & ADJUSTMENTS

WARNING

Before attempting any adjustments, maintenance,

service, or repairs, stop engine and auger/impeller,

always remove key from ignition switch, remove

spark plug wire and secure wire away from spark

plug.

4.1 AUGER/IMPELLER and WHEEL DRIVE BELT

ADJUSTMENT/REPLACEMENT

When operating machine release the auger/impeller

clutch control, auger/impeller should come to a

complete stop in 5 seconds. If auger/impeller does not

come to a complete stop in the required time, check

and adjust belt tension. Inspect belt frequently for signs

of excessive wear. Observe drive belt for slippage due

to wear when operating machine. If slippage does

occur, adjust as follows.

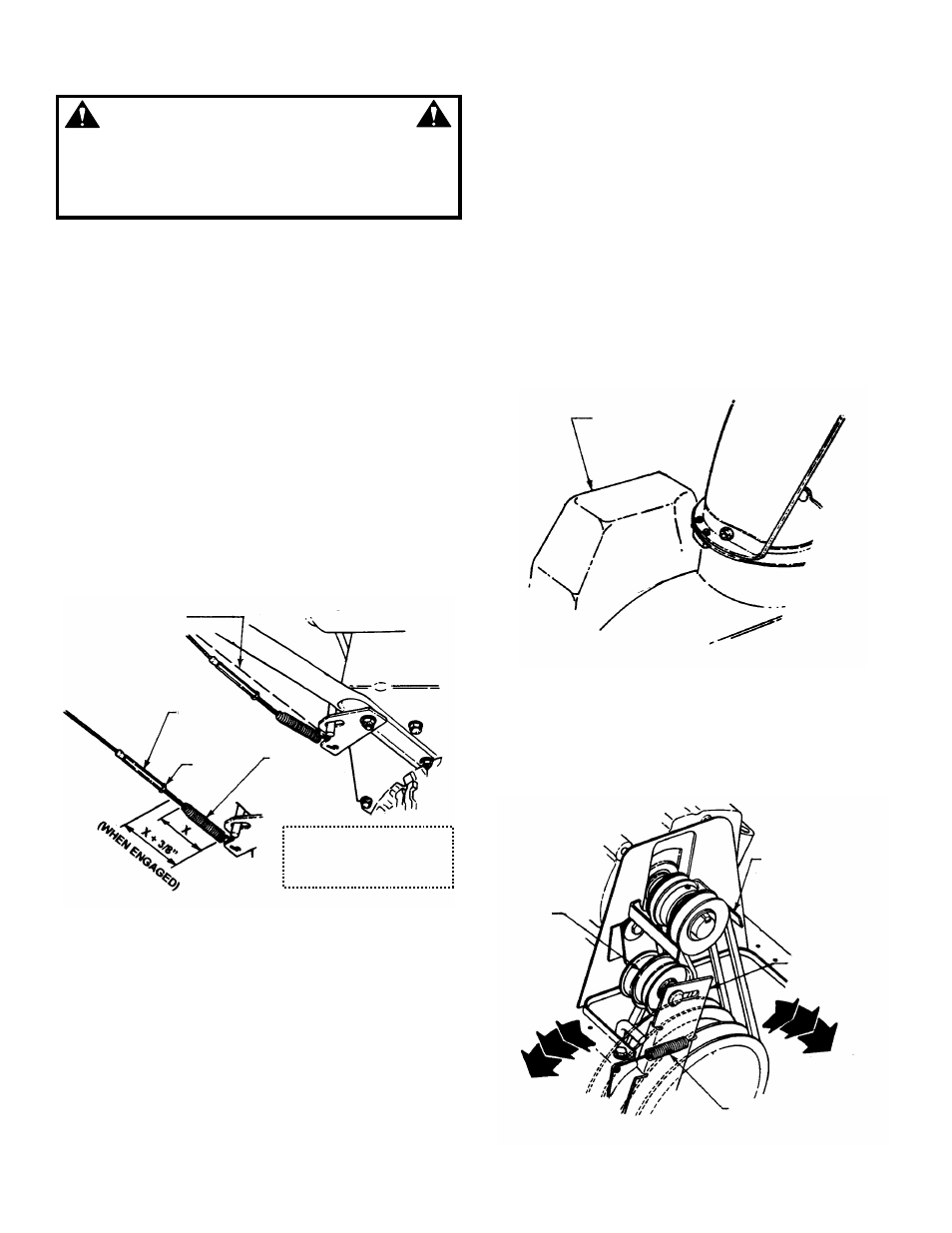

4.1.1. AUGER and DRIVE BELT ADJUSTMENT

(CABLE

ADJUSTMENT)

1. Measure control cable extension from a relaxed

position to full extended position. Move control lever

against handle. Measure from the top of spring (The

top is in relation to where spring connects into

connector). The cable spring should stretch 3/8”

when the auger clutch control lever is depressed.

See Figure 4.1.

FIGURE 4.1

2. Adjust control cable by loosening jam nut at the

upper end of cable. Hold threaded end of cable and

then turn cable clockwise or counter clockwise until

correct extension is achieved. Retighten jam nut.

IMPORTANT: DO NOT rotate cable beyond the point to

where all of the slack is out of cable. Cables have to

have a certain amount of slack: When control lever is in

the released position the cable slack allows: 1) Auger

brake to stop auger/impeller. 2) Wheel drive to

disengage. If all of the adjustment is utilized at the cable

connector go to Section 4.1.2. for alternate adjustment.

4.1.2. AUGER BELT ADJUSTMENT

(IDLER PULLEY ADJUSTMENT)

NOTE: Wheel drive belt idler pulley is not adjustable. If

upper cable adjustment performed in Section 4.1.1.

and correct cable extension can not be accomplished,

adjustment can be made at the idler pulley. All

adjustment made in Section 4.1.1. will have to be

reversed from the upper end of cable.

1. Loosen jam nut at the end of cable. Hold

threaded end of cable and then turn metal housing

of cable counter clockwise until threaded portion of

cable is extracted from metal housing. Reinstall 1/2”

of the threaded portion of cable back into metal

housing. Retighten jam nut.

2. Remove belt cover. See Figure 4.2.

FIGURE 4.2

3. Loosen nut and bolt that secures the idler pulley.

Move idler toward belt for more tension or away

from belt for less tension. See Figure 4.3. Retighten

bolt and nut securely.

FIGURE 4.3

CABLE MUST BE

SLACK WHEN

CLUTCH HANDLE IS

RELEASED

CABLE

CONNECTOR

JAM

NUT

CABLE

SPRING

SPRING SHOULD

STRETCH 3/8” WHEN

LEVER IS DEPRESSED

REMOVE

BELT

COVER

IDLER

PULLEY

NUT

BLOWER BELT GUIDE

(SHOULD CLEAR

BELT & PULLEY 1/16”

TO 1/8”)

BLOWER IDLER

ARM

TIGHTEN

LOOSEN

BLOWER IDLER

RETURN SPRING