Forged pistons, Fuel cooler, Omulti-stage induction – Suzuki DF250SS User Manual

Page 6: Torque curve, Air flow in multi-stage induction module, Lower rpm high rpm

5

Alumite coating

Piston

Resin coating

T

O

R

Q

U

E

(5

0

N

•

m

)

LOW

MID

ENGINE SPEED (rpm)

HIGH

without Multi-Stage Induction

with Multi-Stage Induction

Torque Curve

Multi-Stage Induction Module

Air Flow in Multi-Stage Induction Module

Lower rpm

High rpm

Close

Open

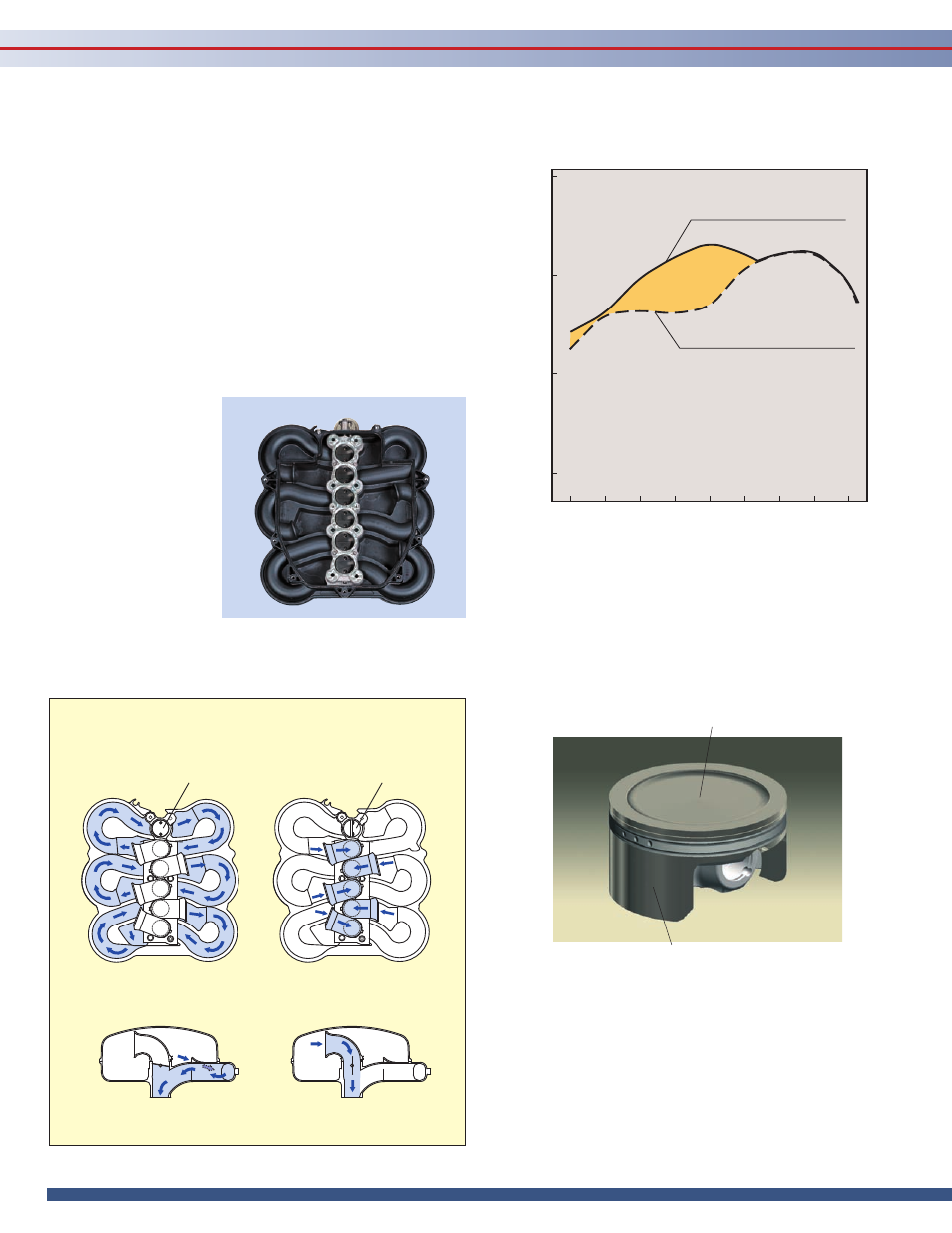

Forged Pistons

The upper portion of each piston used in the DF250SS is treated

with an alumite coating that increases heat resistance. A resin

coating applied to the piston skirt improves resistance to wear and

reduces friction.

Fuel Cooler

The cooler the fuel the denser it is, and the denser it is, the

more performance it delivers. The DF250SS incorporates a water -

cooled fuel rail in the fuel delivery system. The fuel is cooled before

it is injected into the cylinder resulting in better combustion and

better performance.

O

Multi-Stage Induction

Suzuki engineers also utilized Suzuki’s Multi-Stage Induction,

which changes intake manifold pipe length according to engine rpm

to enhance engine performance. The DF250SS utilizes two intake

manifold pipes per cylinder; one operates at low engine rpm and

the other takes over at higher rpm. During low engine rpm, air

enters the combustion chamber through the longer, curved mani-

fold pipe. The particular length of this pipe allows just the right

amount of fresh air into the chamber to improve combustion and

boost low-end torque.

As engine rpm increases, a valve on the intake manifold opens,

letting air enter directly

into the combustion

chamber through the

short, straight intake pipe.

This allows a greater

volume of air into the

chamber, increasing the

engine’s ability to breathe

at high rpm, thus

improving high-end

power output.

T