Df250ss product information, Vvt (variable valve timing), Diagram of vvt mechanism – Suzuki DF250SS User Manual

Page 5

4

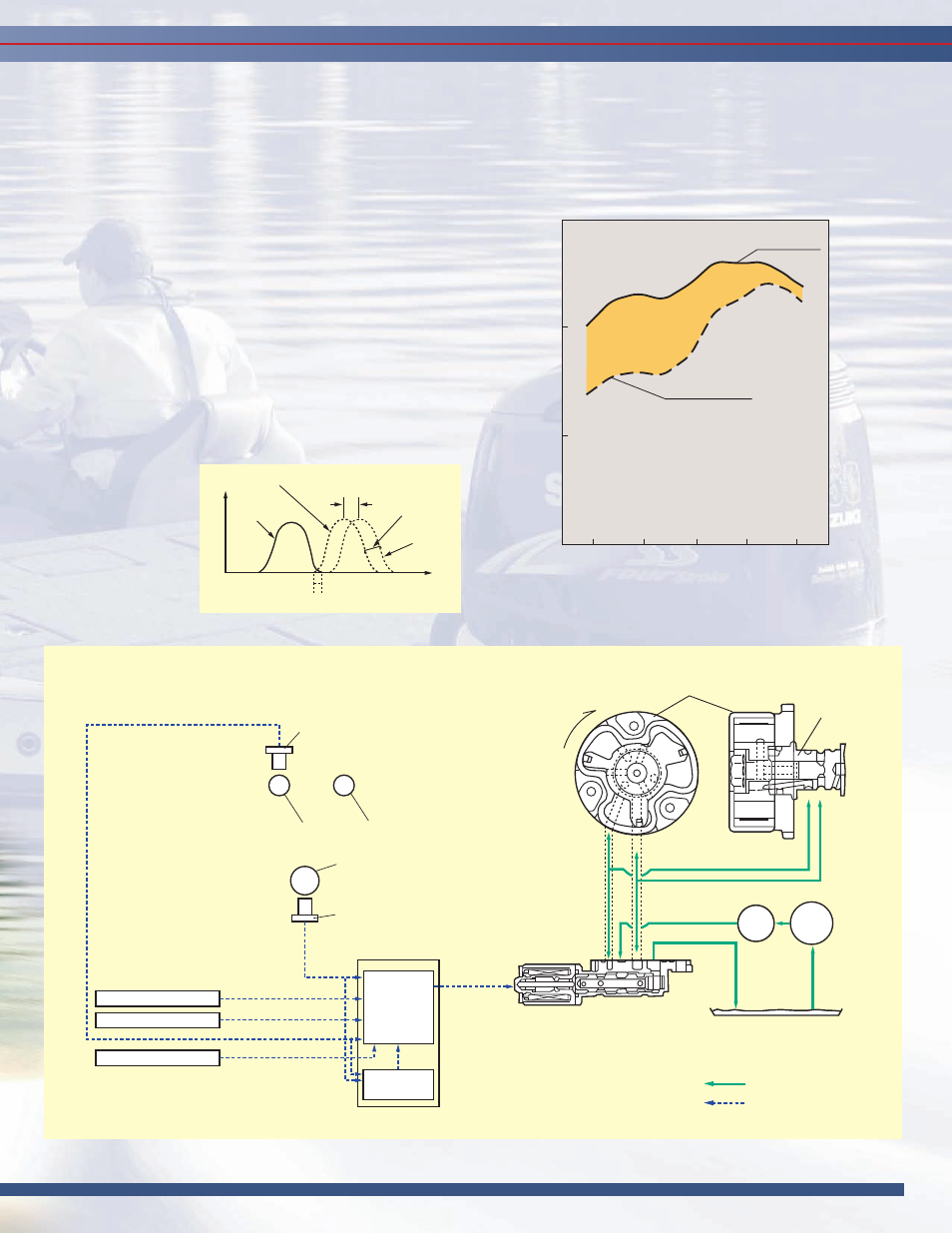

Diagram of VVT Mechanism

D

Suzuki Technologies Deliver Outstanding Performance

Camshaft Position Sensor

Rotation Direction

VVT Actuator

Throttle Opening Angle

Water Temp

Feed

back

Cam Position

Crank

Position

Manifold Pressure

Water Temp Sensor

Throttle Sensor

Map Sensor*

Intk Camshaft

Ex Camshaft

Crankshaft Position Sensor

Duty Control

Crankshaft

ECM

Target

Advance

Actual Valve

Timing

Intk Camshaft

Retard

Advance

Drain

Oil

Filter

Oil

Pump

Oil Pan

Engine Oil Flow

Oil Control Valve (OCV)

Signal

*Manifold Absolute Pressure Sensor

DF250SS PRODUCT INFORMATION

T

O

R

Q

U

E

LOW

MID

ENGINE SPEED

HIGH

without VVT

with VVT

Valve Overlap

V

a

lv

e

L

if

t

Ex Valve

Advance

40° Movable Angle

Intk Valve

Retard

Crank Angle

VVT (Variable Valve Timing)

Suzuki engineers started off in a big way by designing the

DF250SS based on a big block 4.0-liter engine, the largest displace-

ment found in this class. This V6 engine features an aggressive cam

profile, delivering maximum output and performance at high rpm,

and Suzuki’s advanced Variable Valve Timing (VVT), provides the

DF250SS with the torque needed to boost low- to mid-range

acceleration. VVT provides this boost by adjusting the intake valve

timing, allowing intake valves to open before the exhaust valves are

fully closed. This process creates a momentary overlap in the

timing where both sets of valves are open. With VVT, this overlap

can be increased or

decreased by altering

intake timing with the

camshafts to optimize

timing for low- and

mid-range operation.

■