Scag Power Equipment STT-31BSD User Manual

Page 29

Section 6

25

2002 CCB

MOUNTING

HARDWARE

MOUNTING

HARDWARE

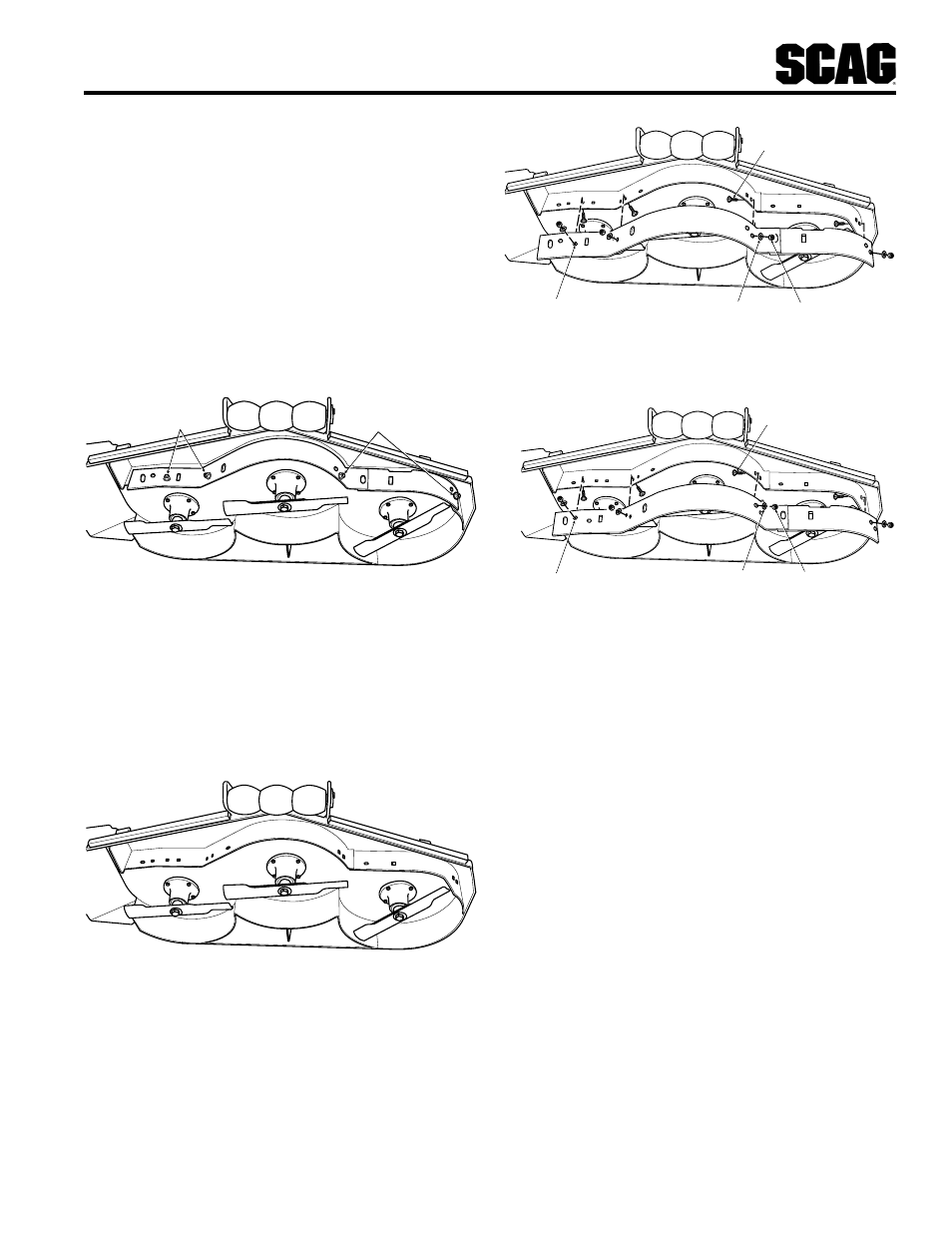

Figure 6-8. Custom Cut Baffle

3. Move the Custom-Cut Baffle to desired position.

(See Figures 6.9 through 6.11 for position).

4. Reinstall the mounting hardware as shown. (See

Figures 6.10 though 6.11). Torque hardware to

39ft.lbs.

Figure 6-9. 3" Custom Cut Baffle Position

2002 CCB - 3" Setting

2002 CCB - 3-1/2" Setting

CARRIAGE BOLT

BOTTOM SET OF HOLES

FOR 3-1/2" SETTING

FLATWASHER

ELASTIC STOP

NUT

2002 CCB - 4" Setting

CARRIAGE BOLT

FLATWASHER

ELASTIC STOP

NUT

TOP SET OF HOLES

FOR 4" SETTING

Figure 6-11. 4" Custom Cut Baffle Position

To adjust the Custom-Cut Baffle height:

1. Place the cutter deck in the transport position.

2. Remove the hardware securing the Custom-Cut

Baffle to the cutter deck. (See Figure 6.8)

-NOTE-

Hardware location used in the illustrations are

for reference only. Location of hardware may

vary depending on cutter deck size.

Figure 6-10. 3-1/2" Custom Cut Baffle Position

- STT (129 pages)

- SWZ (36 pages)

- V-RIDE SVR48V-24FX (63 pages)

- SFZ52-19KA (20 pages)

- 79999 (84 pages)

- TURF TIGER STT61V-25CH-LP (76 pages)

- STC61-25CV-FR (110 pages)

- STC61V-25CV-FR (117 pages)

- STC SMTC-48V (31 pages)

- SMWC-61V (34 pages)

- STWC WILDCAT SMTC-48V (34 pages)

- WALK-BEHIND SWZ36A-16KAI (92 pages)

- STWC61V-27CV (120 pages)

- GC-STT-CS (28 pages)

- SCR (75 pages)

- GC-STWC-61V (20 pages)

- SCAG SCR (75 pages)

- SW48V-15KH (76 pages)

- GC-STC (19 pages)

- STT61V-35BV-SS (143 pages)

- TIGER CAT STC52V-27CV (80 pages)

- TURF TIGER STT61V-27KA (138 pages)

- FREEDOM Z SFZ61-28BS (69 pages)

- TURF TIGER STT61V-35BVAC (95 pages)

- V-RIDE SVR61V-29FX (65 pages)

- WILDCAT STWC61V-26KA-LC (122 pages)

- STWC (106 pages)

- STC (64 pages)

- SWZU (92 pages)

- TURF TIGER STT61V-31KB-DF (76 pages)

- STT61V-25KBD-SS (114 pages)

- 37621220 (18 pages)

- SFW36-16BV (48 pages)

- FREEDOM Z SFZ (109 pages)

- TIGER CAT STC52V-27CV-SS (116 pages)

- TURF TIGER STT61V-31EFI-SS (116 pages)

- TURF TIGER 6201 (28 pages)

- TURF TIGER STT61V-28CAT-SS (35 pages)

- SWU (40 pages)

- MODEL TS (14 pages)

- SWZV (105 pages)

- SSZ (41 pages)

- TURF TIGER STT61V-29KB-DF (72 pages)

- TURF TIGER STT61V-25KBD (79 pages)