M1 maintenance interval operations table, General information – Sterling Trucks Acterra MX User Manual

Page 22

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

the

Acterra

®

Driver’s Manual.

NOTE: Numbers in this table are maintenance opera-

tion reference numbers matching those in the text of

this manual.

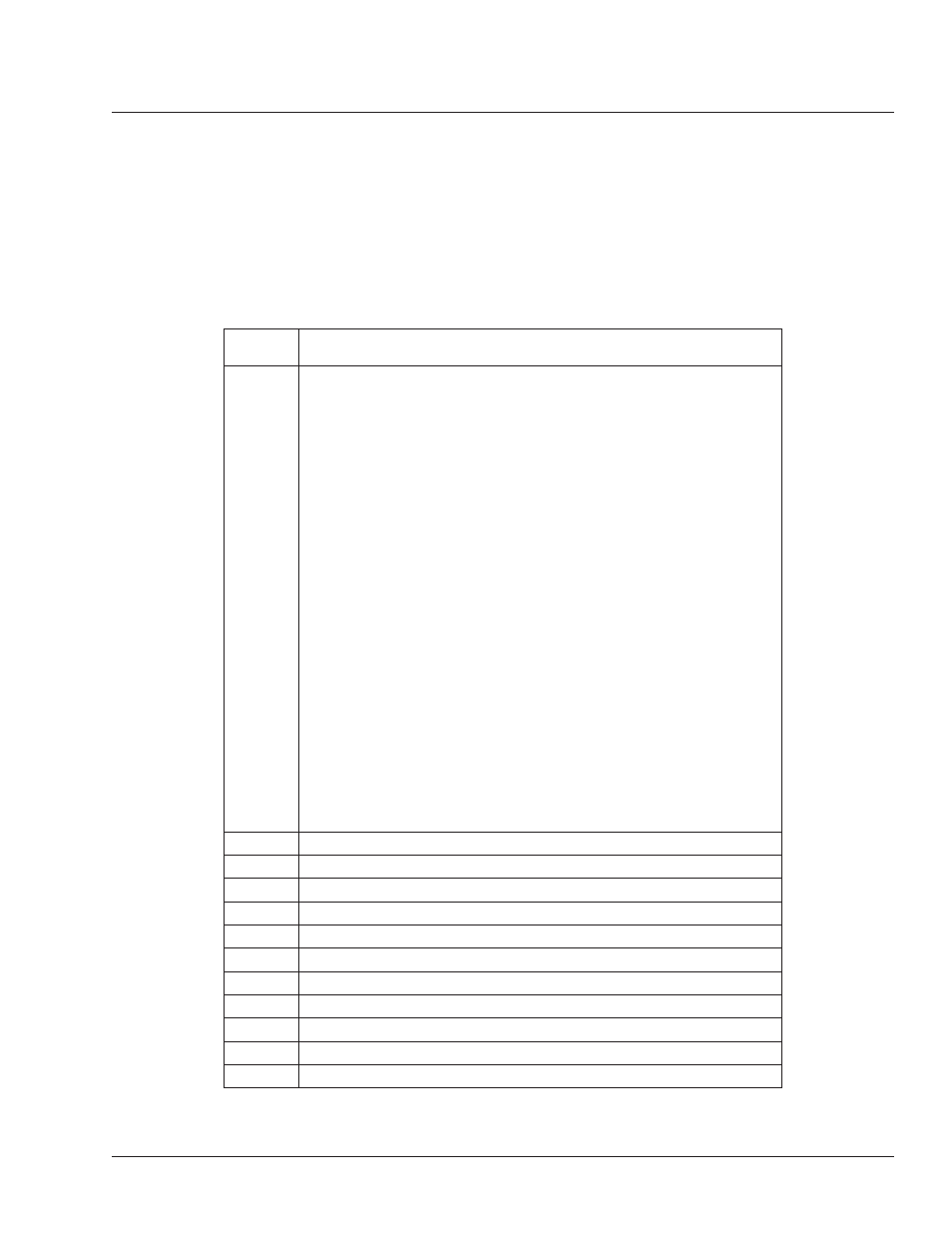

M1 Maintenance Interval Operations

Maint.

Oper. No.

M1 Maintenance Interval Operations

Lubrication and Fluid Level Check:

•

Clutch Release Bearing and Release Cross-Shaft Lubricating

•

Hydraulic Fluid Level Checking

•

Manual Transmission Fluid Level Checking

•

Fifth Wheel Lubricating

•

Trailer Electrical Connector Lubricating

•

Suspension Lubricating

•

Knuckle Pin Lubricating

•

Tie-Rod End Lubricating

•

All-Wheel-Drive Front Axle Oil Level Checking

•

Axle Lubricant Level Checking

•

Driveline Lubricating

•

Foot Brake Valve Actuator Lubricating, Bendix E–8P

•

Automatic Slack Adjuster Lubricating, Meritor

•

Automatic Slack Adjuster Lubricating, Gunite

•

Automatic Slack Adjuster Lubricating, Haldex

•

Drag Link Lubricating

•

Power Steering Reservoir Fluid Level Checking

•

Power Steering Gear Lubricating (Ross TAS Series)

•

Weatherstrip, Door Latch, and Door Hinge Lubricating

Fifth Wheel Inspecting

Suspension Inspecting

Tie-Rod End Inspecting

Axle Breather Checking

Driveline Inspecting

Air Dryer Inspecting, Bendix AD–9

Air Brake Valve Inspecting and Leak Checking, Bendix BP–R1

Air Brake Valve Operation Checking

Relay Valve Checking, Midland

Quick Release and Flipper Valves Checking, Midland

Brake Chamber Inspecting (All Models)

General Information

00

M1 Maintenance Interval Operations Table: 00–10

Acterra Maintenance Manual, October 2008

00/15