Cone-fire, Chapter 3, Pyrometric witness cones – Sentry Industries Sentry 2.0 User Manual

Page 8: Firing schedules

Chapter 3

Cone-Fire

Cone-Fire mode is based on

pyrometric cones. It is not designed for

heat treating, glass fusing and enameling.

For these firings, see “Ramp-Hold,”

page 12. Use Ramp-Hold to fire ceramic

pieces that require a custom firing

schedule, such as some types of stone-

ware sculpture or crystalline glaze.

Pyrometric Witness Cones

The Sentry shuts off automatically without cones. Never-

theless, every ceramic firing should include at least one wit-

ness cone (also called the shelf cone). The witness cone is

the most accurate measurement of heat work in a ceramic

firing.

If you fire the same size load and type of ware regularly,

the witness cones let you compare one firing to the next and

alert you when something is wrong. For example, if the wit-

ness cone bends less and less with each consecutive firing,

this may indicate thermocouple temperature drift.

Note: If the bending of the witness cone does not

match the Cone-Fire shut-off, you may want to ad-

just Cone Offset or Thermocouple Offset. See

pages 17 - 19. If the witness cones bend inconsis-

tently from one firing to another, see “Sentry Trou-

bleshooter,” a separate publication.

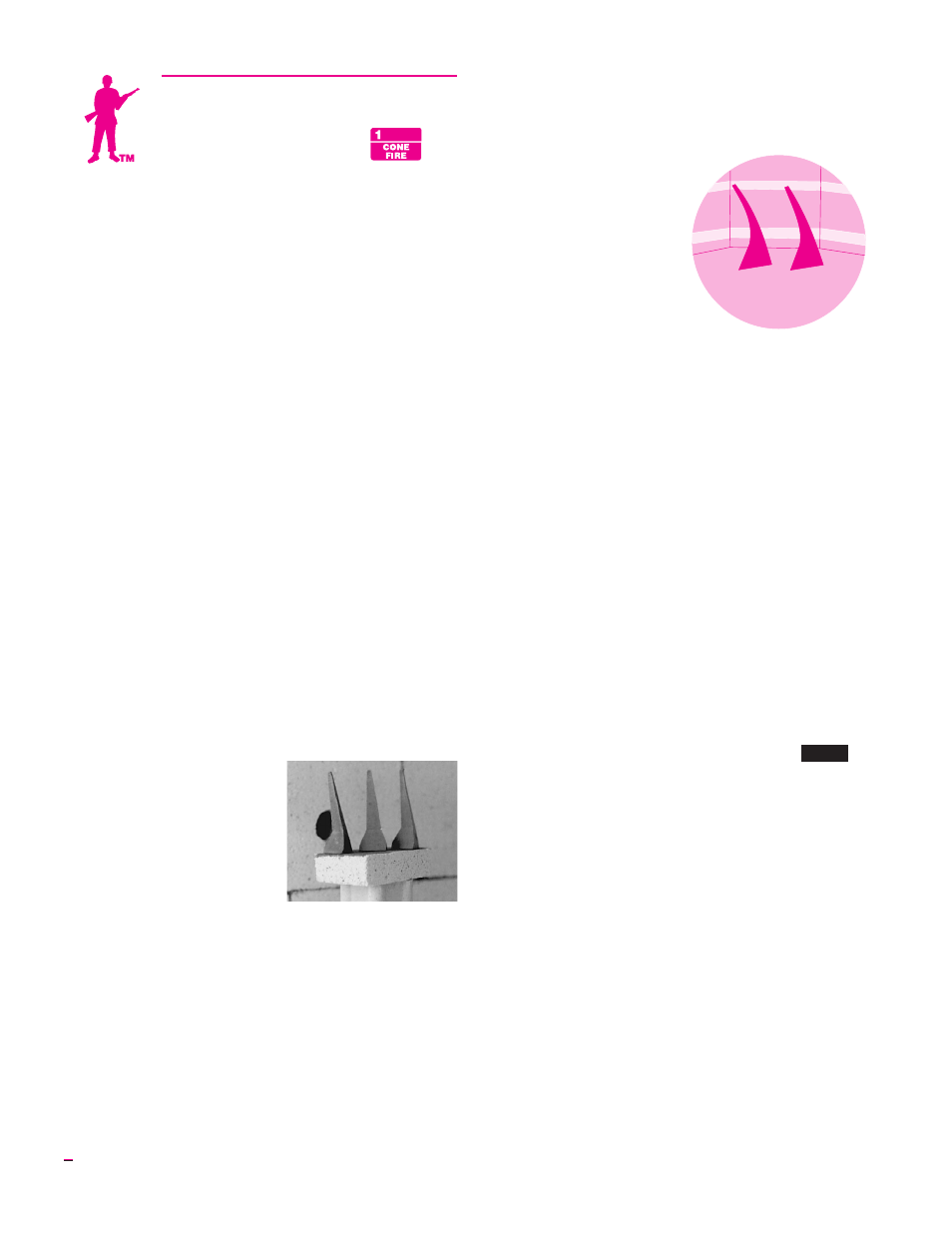

How to Position Cones on the Shelf

Position the witness cones

so that you can see them

through a peephole during fir-

ing. If the kiln takes longer than

usual to fire, you may wonder if

something has gone wrong and

the kiln is overfiring. But by

seeing the cones, you will know

how the firing is progressing.

If you follow these guide-

lines, you should be able to see

the cones even at cone 10:

■

Place the cones 8” - 12” away from a peephole. Posi-

tioning them closer makes them difficult to see.

■

Have enough space around the cones to keep them from

touching a piece of ware when they bend.

■

Position cones so that when viewed from the peephole,

they are silhouetted by an element on the opposite kiln

wall. (Keep cones at least 2” from an element.)

■

The element that silhouettes the cones should be level

with the lower part of the cone. If the element is in line

with the upper part of the cone, you won’t be able to see

the cone when it bends.

■

If you use the three

cone system, always

have the higher tem-

perature cone on the

same side in every fir-

ing. Otherwise you can

lose track of which cone

is which.

■

Wear firing safety

glasses when viewing

the cones through the

peephole.

See your dealer if in

doubt about which cone number to use with each clay and

glaze.

Firing Schedules

Cone-Fire uses three firing schedules:

■

Low fire cones 022 - 011

■

Medium fire cones 010 - 01

■

High fire cones 1 - 10

Should you ever want to customize a Cone-Fire program,

transfer the firing schedule to Ramp-Hold. See Appendix B,

pages 26 - 27.

During a cone firing, press 5 (Present Status) to see

which stage, or segment, of the firing the kiln has reached.

The number displayed will be a segment number from one

of these firing schedules.

Note: Pre-Heat shows in Present Status as

PRHT

.

It is not given a separate segment number.

Firing time in each segment is approximate and depends

on the age of elements, voltage, size of load, and the firing

speed you have chosen.

CAUTION: Cone numbers beginning with 0 are

lower in temperature than those without the 0.

When programing a Cone-Fire, be sure you know

the difference between an 05 and 5. See “Tempera-

ture Equivalents Chart for Orton Self-Supporting

Pyrometric Cones,” Appendix D, page 30.

8

Use self-supporting witness

cones on the shelf. They stand

upright without cone holders.

Silhouette the lower part of the cone

against an element. Keep the cone 8”

- 12” away from the peephole.