State TPG 150 140 NEA User Manual

Page 7

7

Where an existing chimney or vent is to be used, be sure that the

chimney or vent has adequate capacity for the number and sizes

of gas appliances being vented through it. Inspect the chimney

or vent and remove all soot or other obstructions, which will retard

free draft.

Vent piping making horizontal runs must have a minimum upward

slope toward the chimney or vent of 1/4” per foot. Vent pipe

length should be kept as short as possible. Be sure that the vent

pipe does not extend beyond the inside wall of a chimney.

In venting systems, where a continuous or intermittent back

(positive) draft is found to exist, the cause must be determined

and corrected. In some cases, a special vent cap may be required.

WATER LINE CONNECTIONS

The water heater may be installed by itself, or with a separate

storage tank, on both single and two-temperature systems. When

used with a separate storage tank, the circulation may be either

by gravity or by means of a circulating pump.

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the local code authority having jurisdiction. Good practice requires

that all heavy piping be supported.

THERMOMETERS (Not supplied)

Thermometers should be obtained and field installed as shown

in the installation diagrams.

Thermometers are installed in the system as a means of detecting

the temperature of the outlet water.

RELIEF VALVE

This water heater has been provided with an ASME rated pressure

and temperature relief valve.

In addition to the appliance relief valve, each remote storage tank,

which may be used in conjunction with this appliance, shall also

be installed with a properly sized, rated and approved temperature

(ANSI) and pressure (ASME) relief valve(s).

WARNING

THE PURPOSE OF A RELIEF VALVE IS TO AVOID EXCESSIVE

PRESSURE OR TEMPERATURE INTO THE STEAM RANGE,

WHICH MAY CAUSE SCALDING AT FIXTURES, TANK

EXPLOSIONS, SYSTEM OR HEATER DAMAGE. NO VALVE IS

TO BE PLACED BETWEEN THE RELIEF VALVE AND THE

TANK.

A DRAIN LINE MUST BE CONNECTED TO THE RELIEF VALVE

TO DIRECT DISCHARGE TO A SAFE LOCATION TO AVOID

SCALDING OR WATER DAMAGE. THIS LINE MUST NOT BE

REDUCED FROM THE SIZE OF THE VALVE OUTLET AND

MUST NOT CONTAIN VALVES, RESTRICTIONS NOR SHOULD

IT BE LOCATED IN FREEZING AREAS. DO NOT THREAD OR

CAP THE END OF THIS LINE. RESTRICTED OR BLOCKED

DISCHARGE WILL DEFEAT THE PURPOSE OF THE VALVE

AND IS UNSAFE. DISCHARGE LINE SHALL BE INSTALLED

TO ALLOW COMPLETE DRAINAGE OF BOTH THE VALVE AND

LINE.

Your local code authority may have other specific relief valve

requirements.

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation codes

for your area.

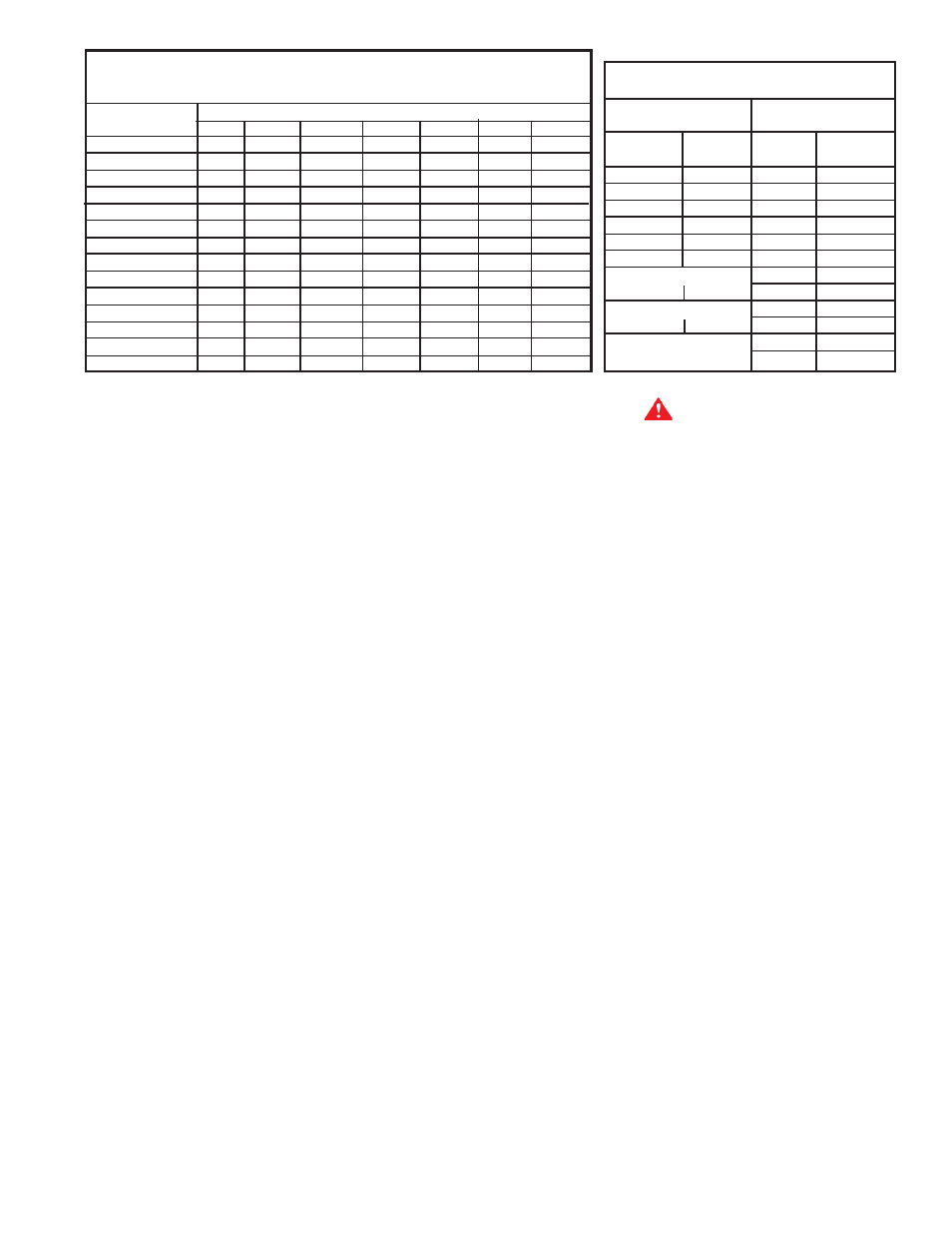

Size the main gas line in accordance with Table 3. The figures

shown are for straight lengths of pipe at 0.3 in. w.c. pressure

drop, which is considered normal for low-pressure systems. Note

that fittings such as elbows and tees will add to the pipe pressure

drop.

Equivalent lengths of standard pipe in feet for listed fittings (add

below values to Table 3).

Install vent lines from main gas regulator and (if applicable) a

diaphragm gas valve. Vent line should be run to the outside of

the building, terminating clear of windows or fresh air intakes.

Outside terminal of vent should have a screen to prevent insects

from building nests in vent pipe. The vent should terminate in a

manner, which will preclude the possibility of water, snow, dirt or

other matter from entering the line.

CORRECTION FACTORS

Specific Gravity Pressure Drop

Other than 0.60 Other than 0.3

Specific Multplier Pressure Multiplier

Gravity

Drop

0.50

1.10

0.1

0.577

0.60

1.00

0.2

0.815

0.70

0.926

0.3

1.00

0.80

0.867

0.4

1.16

0.90

0.817

0.6

1.42

1.00

0.775

0.8

1.64

Propane - Air

1.0

1.83

1.10

0.740

2.0

2.58

Propane

3.0

3.16

1.55

0.622

4.0

3.65

6.0

4.47

8.0

5.15

CAPACITY OF PIPE - NATURAL GAS IN CUBIC FEET PER HOUR

Maximum Based Upon Pressure Drop of 0.3” w.c. and Specific Gravity

of 0.60 and Maximum Gas Pressure of .5 psig.

Pipe Length

Pipe Size - Inches (IPS)

In Feet

1

1 1/4

1 1/2

2

2 1/2

3

4

10

520

1050

1600

3050

4800

8500

17500

20

350

730

1100

2100

3300

5900

12000

30

285

590

890

1650

2700

4700

9700

40

245

500

760

1450

2300

4100

8300

50

215

440

670

1270

2000

3600

7400

60

195

400

610

1150

1850

3250

6800

70

180

370

560

1050

1700

3000

6200

80

170

350

530

990

1600

2800

5800

90

160

320

490

930

1500

2600

5400

100

150

305

460

870

1400

2500

5100

125

130

275

410

780

1250

2200

4500

150

120

250

380

710

1130

2000

4100

175

110

225

350

650

1050

1850

3800

200

100

210

320

610

980

1700

3500

NOTE: Use Multiplier at right for other specific gravities and pressure drops.

TABLE 2