A. table clearance, B. tracking – Woodstock W1410 User Manual

Page 11

-10-

Shop Fox

®

Fence

SECTION III: ADJUSTMENTS

Your Shop Fox

®

Fence has been pre-adjusted at

the factory. However, it will be necessary to check

and fine tune each adjustment with the fence

installed on your saw. A quality steel rule and

square will help you bring your new fence into

perfect alignment.

A. TABLE CLEARANCE

It is important to minimize the gap between the

bottom of the fence and the table so thin material

will not slide under the fence during operation.

This clearance must be uniform along the table

surface. It is also very important that the fence

does not contact the table surface when sliding

from side to side.

With the fence mounted on the rails, try sliding it

over the table. Make sure the fence is supported

by all three rollers. Gauge the gap under the fence

at various locations over the table surface. There

should be a uniform gap of

1

⁄

16

" between the bot-

tom of the fence and the tabletop. If the gap is not

uniform, loosen the rail mounting bolts and raise

or lower one end of one or both rails to achieve a

uniform gap.

If ripping thin laminates or veneers, clamp an

auxiliary fence to the Shop Fox

®

Fence so it rests

right on the table. This will ensure that thin mate-

rial will not slip under the fence.

B. TRACKING

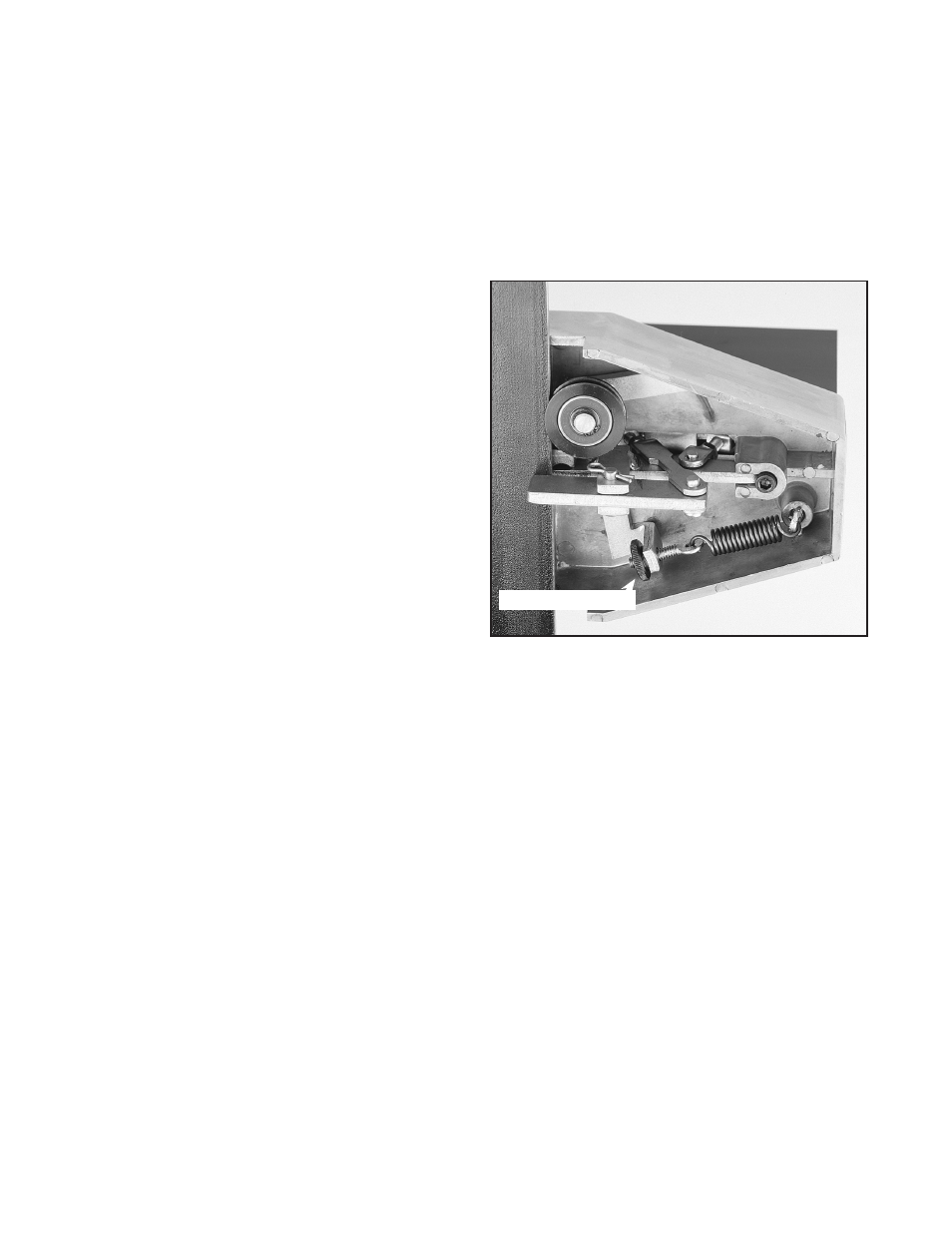

The spring tension on the rear roller will affect

the ease with which the fence will travel from

side to side. Too much spring tension will restrict

free movement of the fence on the rails. Too little

tension may allow the fence to derail if moved

abruptly or allow the fence to skew slightly when

being locked down. Tension is easily adjusted

by reaching underneath the rear carriage (#44)

and turning the adjustment nut (#48). Figure 10.

Tightening the adjustment nut onto the stud will

Step 1.

Test ease of movement relative to tracking qual-

ity. The best way to do this is to experiment with

the rear roller tension until a setting is found that

allows comfortable motion and tracking. Grab

the fence by the handle and abruptly slide it back

and forth several times. When changing direction,

both front rollers should stay engaged to the rails.

If either roller tends to move away from the rail,

increase the rear spring tension and repeat the

test.

Step 2.

Continue to increase or decrease rear spring

tension as necessary until all rollers remain in

constant contact with the rails when changing

directions. Don't increase tension to the point that

movement becomes restricted.

Figure 10. Rear spring adjustment.

Adjustment nut

increase the spring tension while loosening the

adjustment nut will reduce the tension. To adjust

tracking: