Iec squirrel-cage motors, Special versions 14 – Siemens IEC Squirrel-Cage Motor 1LA7 User Manual

Page 14

IEC Squirrel-Cage Motors

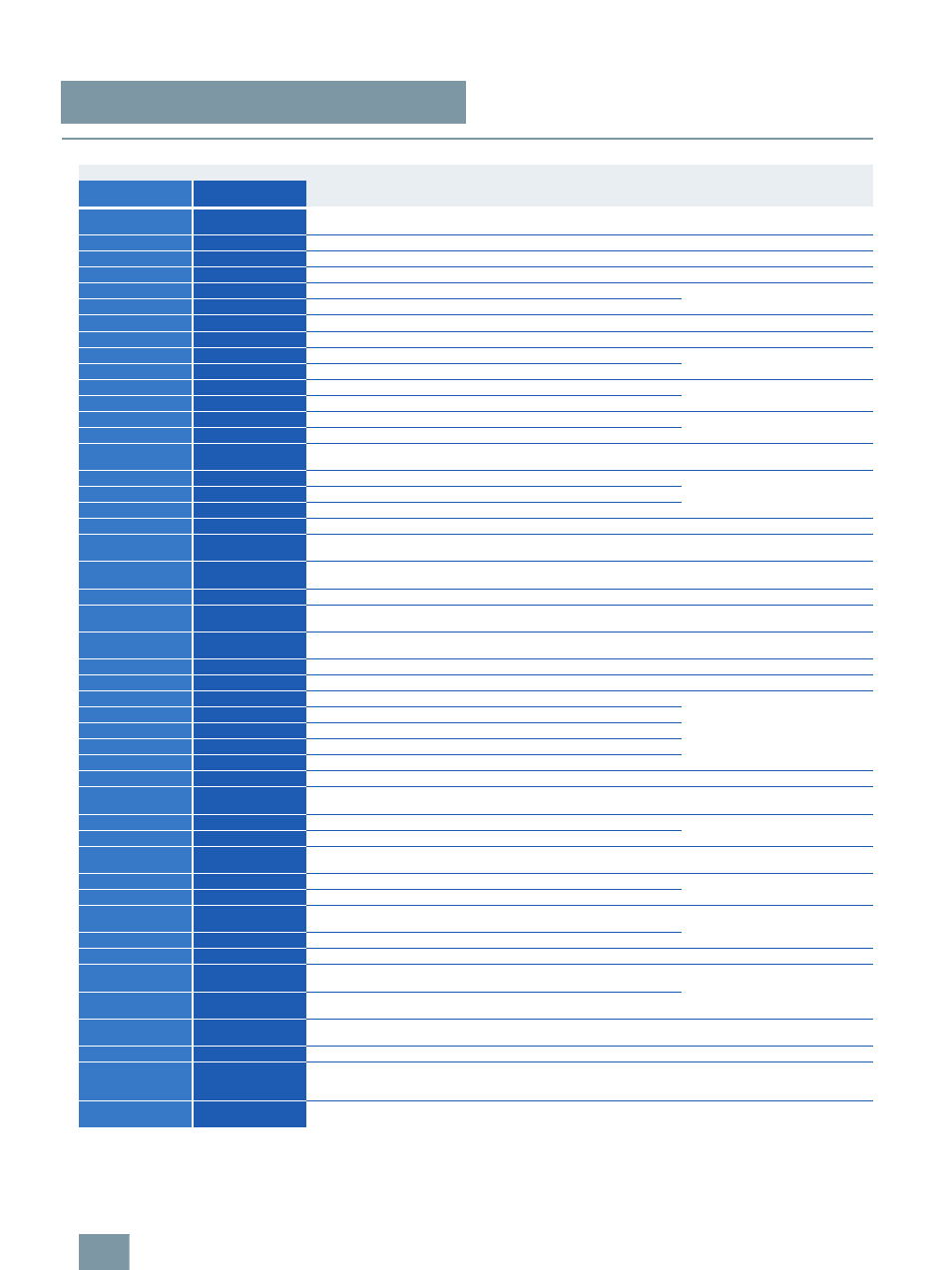

Recoding overview of Order No. from motor series 1LA7/1LA9 to 1LE1

Special versions

14

Siemens Supplement to Catalog D 81.1 · 2008

■

Selection and ordering data

(continued)

z

This order code remains to be available for 1LA7/1LA9 motors only.

Order code

Order code

Special version

Category

Motors

1LA7/1LA9

Motors

1LE1

K30

z

VIK design (comprises Zone 2 for mains-fed operation, without Ex nA II

marking on rating plate)

Design for Zones 1, 2, 21 and 22

according to ATEX

K31

M10

Second rating plate, loose

Rating plate and extra rating plates

K35

F76

Metal external fan

Heating and ventilation

K36

L25

Special bearing for DE and NDE, bearing size 63

Bearings and lubrication

K37

F77

Low-noise version for 2-pole motors with clockwise direction of rotation

Mechanical design and degrees of

protection

K38

F78

Low-noise version for 2-pole motors with anticlockwise direction of rotation

K40

L23

Regreasing device

Bearings and lubrication

K42

L04

Shaft extension with standard dimensions, without featherkey way

Shaft and rotor

K45

Q02

Anti-condensation heaters for 230 V

Heating and ventilation

K46

Q03

Anti-condensation heaters for 115 V

K50

H20

IP65 degree of protection

Mechanical design and degrees of

protection

K52

H22

IP56 degree of protection (non-heavy-sea)

K54

R15

One cable entry, metal

Motor connection and connection

boxes

K55

z

Cable entry, maximum configuration

K82

F50

Manual brake release with lever

Modular technology –

Additional versions

K83

R10

Rotation of the connection box through 90°, entry from DE

Motor connection and connection

boxes

K84

R11

Rotation of the connection box through 90°, entry from NDE

K85

R12

Rotation of connection box through 180°

K94

L20

Located bearing DE

Bearings and lubrication

L00

R50

Next larger connection box/Larger connection box

Motor connection and connection

boxes

L03

H02

Vibration-proof version

Mechanical design and degrees of

protection

L04

L21

Located bearing NDE

Bearings and lubrication

L12

H03

Condensation drainage holes

Mechanical design and degrees of

protection

L13

H04

External earthing

Motor connection and connection

boxes

L36

F74

Sheet metal fan cover

Heating and ventilation

L39

L07

Concentricity of shaft extension in accordance with DIN 42955 Tolerance R Shaft and rotor

L44

R20

3 cables protruding, 0.5 m long

Motor connection and connection

boxes

L45

R21

3 cables protruding, 1.5 m long

L47

R22

6 cables protruding, 0.5 m long

L48

R23

6 cables protruding, 1.5 m long

L49

R24

6 cables protruding, 3 m long

L68

L02

Full key balancing

Balance and vibration quantity

L99

B99

Wire-lattice pallet

Packaging, safety notes,

documentation and test certificates

M14

z

Anti-condensation heater, Ex. 115 V

Heating and ventilation

M15

z

Anti-condensation heater, Ex. 230 V

M27

H07

Non-rusting screws (externally)

Mechanical design and degrees of

protection

M32

M01

Connected in star for dispatch

Packaging, safety notes,

documentation and test certificates

M33

M02

Connected in delta for dispatch

M34

z

Design for Zone 21, as well as Zone 22 for conducting dust (IP65) for

mains-fed operation

Design for Zones 1, 2, 21 and 22

according to ATEX

M35

z

Design for Zone 22 for non-conducting dust (IP55) for mains-fed operation

M37

L01

Balancing without key

Balance and vibration quantity

M38

z

Design for Zone 21, as well as Zone 22 for conducting dust (IP65) for con-

verter-fed operation, derating

Design for Zones 1, 2, 21 and 22

according to ATEX

M39

z

Design for Zone 22 for non-conducting dust (IP55) for converter-fed opera-

tion, derating

M64

H08

Connection box on NDE

Motor connection and connection

boxes

M65

L06

Standard shaft made of non-rusting steel

Shaft and rotor

M68

Standard version

for mounting of

encoder

Mechanical protection for encoder

Mechanical design and degrees of

protection

M69

z

Terminal strip for main and auxiliary terminals

Motor connection and connection

boxes

© Siemens AG 2008