Iec squirrel-cage motors, Special versions 12 – Siemens IEC Squirrel-Cage Motor 1LA7 User Manual

Page 12

IEC Squirrel-Cage Motors

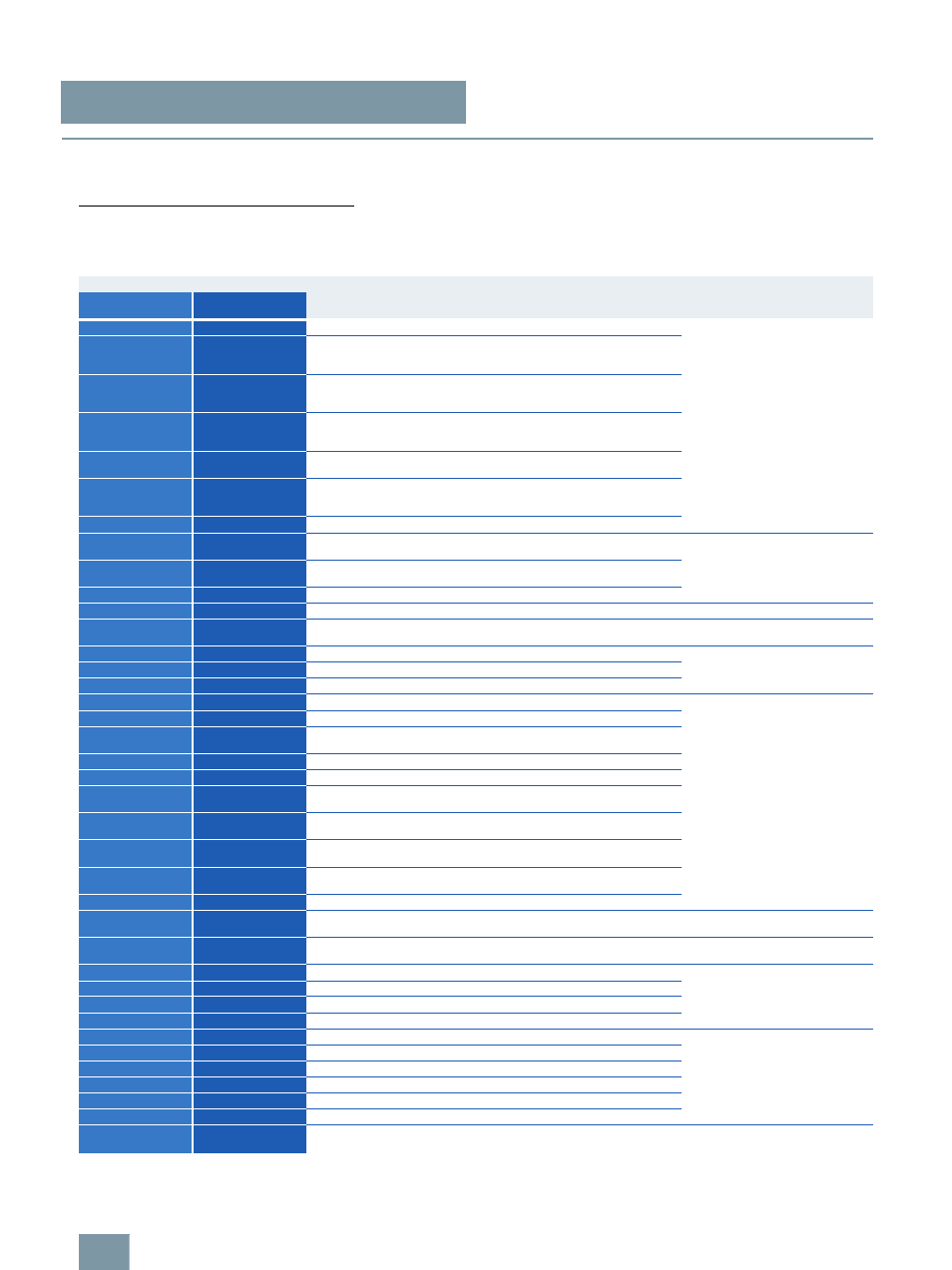

Recoding overview of Order No. from motor series 1LA7/1LA9 to 1LE1

Special versions

12

Siemens Supplement to Catalog D 81.1 · 2008

■

Selection and ordering data

(continued)

Options

Order codes for motors 1LA7/1LA9 and 1LE1

All options are alphanumerically listed according to order codes

in the following table. This concerns a functioning encoding of

the order codes. The technical design of the order codes may

differ.

For detailed information to individual order codes see page

references in Catalog D 81.1 in the Appendix under “Overview

of order codes”.

z

This order code remains to be available for 1LA7/1LA9 motors only.

Order code

Order code

Special version

Category

Motors

1LA7/1LA9

Motors

1LE1

A10

z

PTC thermistors for alarm for converter-fed operation in Zones 2, 21, 22

Motor protection

A11

Position 15

of the Order No.,

letter B

Motor protection through PTC thermistor with 3 embedded temperature

sensors for tripping

A12

Position 15

of the Order No.,

letter C

Motor protection through PTC thermistor with 6 embedded temperature

sensors for alarm and tripping

A23

Position 15

of the Order No.,

letter F

Motor temperature detection with embedded temperature sensor

KTY 84-130

A25

z

Motor temperature detection with embedded temperature sensors

2x KTY 84-130

A31

Position 15

of the Order No.,

letter Z Q3A

Temperature detectors for tripping

A60

z

Installation of 3 PT 100 resistance thermometers in stator winding

B00

B00

Without safety and commissioning note. Customer's declaration of

renouncement required.

Packaging, safety notes,

documentation and test certificates

B01

B01

Complete with one set of safety and commissioning notes per wire-lattice

pallet

B02

B02

Acceptance test certificate 3.1 according to EN 10204

B06

z

Second lubricating plate, supplied loose

Rating plate and extra rating plates

B23

B04

Operating instructions German/English enclosed in print

Packaging, safety notes,

documentation and test certificates

C00

F10

Brake supply voltage 24 V DC

Modular technology –

Additional versions

C01

F12

Brake supply voltage 400 V AC

C02

z

Brake supply voltage 180 V DC, for operation on MM411-ECOFAST

C11

N01

Temperature class 155 (F), used acc. to 155 (F), with service factor (SF)

Windings and insulation

C12

N02

Temperature class 155 (F), used acc. to 155 (F), with increased output

C13

N03

Temperature class 155 (F), used acc. to 155 (F), with increased coolant

temperature

C18

N11

Temperature class 180 (H) at rated output and max. CT 60 °C

C19

N20

Increased air humidity/temperature with 30 to 60 g water per m³ of air

C22

N05

Temperature class 155 (F), used acc. to 130 (B), coolant temperature

45 °C, derating approx. 4 %

C23

N06

Temperature class 155 (F), used acc. to 130 (B), coolant temperature

50 °C, derating approx. 8 %

C24

N07

Temperature class 155 (F), used acc. to 130 (B), coolant temperature

55 °C, derating approx. 13 %

C25

N08

Temperature class 155 (F), used acc. to 130 (B), coolant temperature

60 °C, derating approx. 18 %

C26

N21

Increased air humidity/temperature with 60 to 100 g water per m

3

of air

C27

z

Stamping of Ex nA II on VIK rating plate

Design for Zones 1, 2, 21 and 22

according to ATEX

D01

D01

CCC China Compulsory Certification

Designs in accordance with stan-

dards and specifications

D02

z

Coolant temperature –50 to +40 °C

Coolant temperature and site altitude

D03

D03

Coolant temperature –40 to +40 °C

D04

D04

Coolant temperature –30 to +40 °C

D19

z

Coolant temperature –40 to +40 °C for EX motor

D30

D30

Electrical according to NEMA MG1-12

Designs in accordance with stan-

dards and specifications

D31

D31

Design according to UL with “Recognition Mark”

D32

z

Ex certification for China

D33

z

Certified for Korea according to KS C4202

D40

D40

Canadian regulations (CSA)

D46

D46

PSE Mark Japan

E00

z

Without type test certificate according to ABS 50 °C/CCS 45 °C/

RINA 45 °C, temperature class 155 (F), used according to 155 (F)

Marine version –

Basic marine version

© Siemens AG 2008