Iec squirrel-cage motors, Special versions 13 – Siemens IEC Squirrel-Cage Motor 1LA7 User Manual

Page 13

IEC Squirrel-Cage Motors

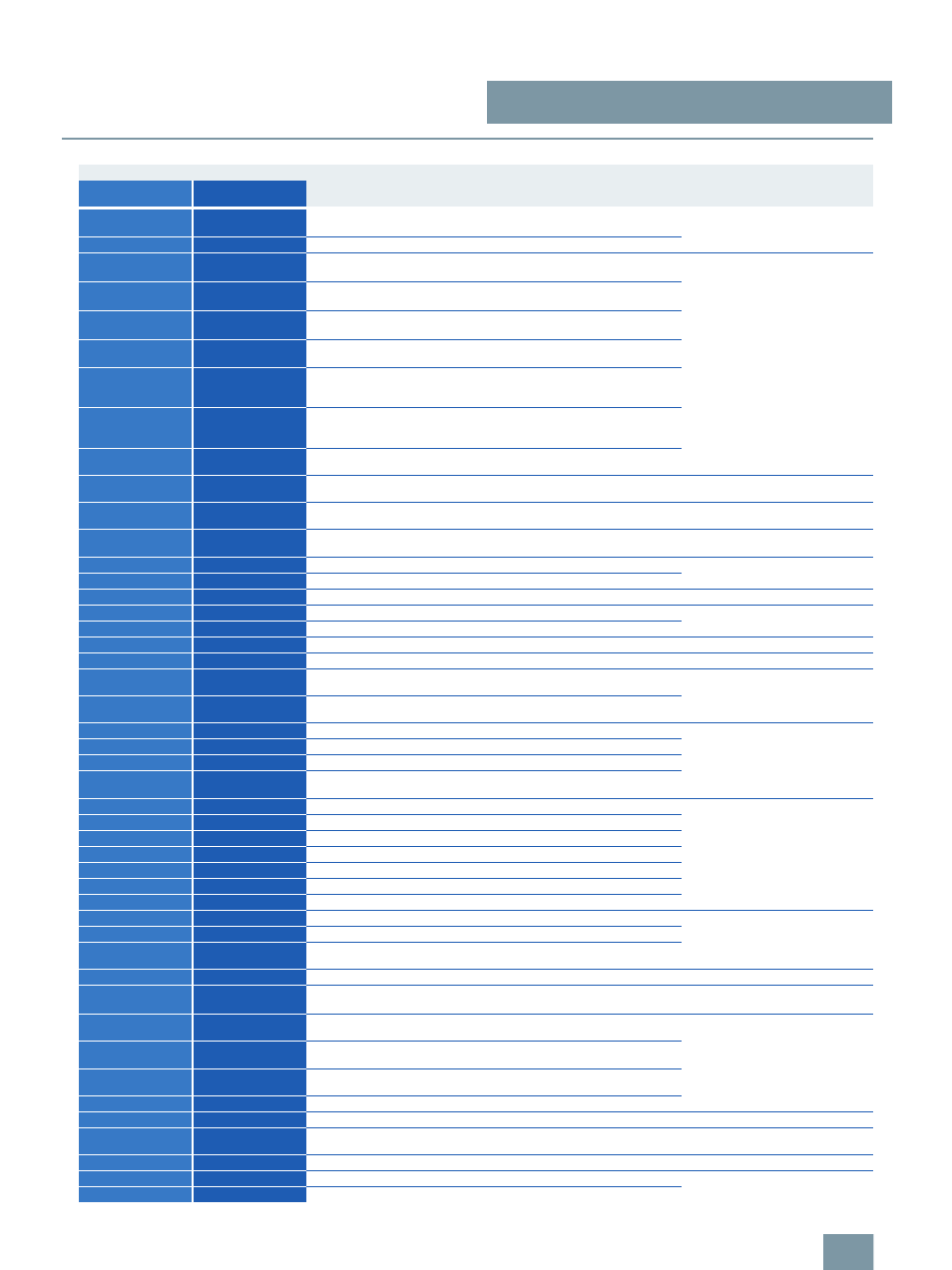

Recoding overview of Order No. from motor series 1LA7/1LA9 to 1LE1

Special versions

13

Siemens Supplement to Catalog D 81.1 · 2008

■

Selection and ordering data

(continued)

z

This order code remains to be available for 1LA7/1LA9 motors only.

Order code

Order code

Special version

Category

Motors

1LA7/1LA9

Motors

1LE1

E09

z

Individual acceptance by marine classification society with supervision of

construction and acceptance test certificate 3.2 according to EN 10204

Marine version –

Acceptance/certification

E10

z

Individual acceptance by marine classification society

E11

z

With/without type test certificate according to GL (Germanischer Lloyd),

Germany, CT 45 °C, temperature class155 (F), used according to 155 (F)

Marine version –

Basic marine version

E21

z

With/without type test certificate according to LR (Lloyds Register), Great

Britain, CT 45 °C, temperature class 155 (F), used according to 155 (F)

E31

z

With/without type test certificate according to BV (Bureau Veritas), France,

CT 45 °C, temperature class 155 (F), used according to 155 (F)

E51

z

With/without type test certificate according to DNV (Det Norske Veritas),

Norway, CT 45 °C, temperature class 155 (F), used according to 155 (F)

E61

z

With/without type test certificate according to ABS (American Bureau of

Shipping), USA, CT 50 °C, temperature class 155 (F), used according to

155 (F)

E71

z

With/without type test certificate according to CCS (Chinese Classification

Society), China, CT 45 °C, temperature class 155 (F), used according to

155 (F)

E80

z

Motor for use in shipping, higher ambient temperature and/or used as

155 (F) according to 130 (B)

F83

z

Type test with heat run for horizontal motors, with acceptance

Marine version –

Acceptance/certification

F83

B83

Type test with heat run for horizontal motors, with acceptance

Packaging, safety notes,

documentation and test certificates

F93

z

Type test with heat run for vertical motors, with acceptance

Marine version –

Acceptance/certification

G17

F70

Mounting of separately driven fan

Modular technology – Basic versions

G26

F01

Mounting of brake

G50

Q01

Measuring nipple for SPM shock pulse measurement for bearing inspection Bearings and lubrication

G55

z

ECOFAST motor plug Han-Drive 10e for 230 V

Δ/400 VY

Motor connection and connection

boxes

G56

z

ECOFAST motor plug EMC Han-Drive 10e for 230 V

Δ/400 VY

H15

z

Prepared for mounting MMI

Special technology

H17

F75

Fan cover for textile industry

Heating and ventilation

H57

G01

Mounting of 1XP8 001-1 (HTL) rotary pulse encoder/

Mounting of 1XP8 012-10 (HTL) rotary pulse encoder

Modular technology – Basic versions

H58

G02

Mounting of 1XP8 001-2 (TTL) rotary pulse encoder/

Mounting of 1XP8 012-20 (HTL) rotary pulse encoder

H61

F70+G01

Mounting of separately driven fan and 1XP8 001-1 rotary pulse encoder

Modular technology –

Combinations of basic versions

H62

F01+F11+G01

Mounting of brake and 1XP8 001-1 rotary pulse encoder

H63

F01+F11+F70

Mounting of brake and separately driven fan

H64

F01+F11+F70+G01

Mounting of brake, separately driven fan and 1XP8 001-1 rotary pulse

encoder

H70

G04

Mounting of LL 861 900 220 rotary pulse encoder

Special technology

H72

G05

Mounting of HOG 9 D 1024 I rotary pulse encoder

H73

G06

Mounting of HOG 10 D 1024 I rotary pulse encoder

H78

z

Prepared for mounting LL 861 900 220

H79

z

Prepared for mounting HOG 9 D 1024 I

H80

z

Prepared for mounting HOG 10 D 1024 I

H86

z

Mounting of explosion-proof rotary pulse encoder for use in Zones 2, 21, 22

H97

F70+G02

Mounting of separately driven fan and 1XP8 001-2 rotary pulse encoder

Modular technology –

Combinations of basic versions

H98

F01+F11+G02

Mounting of brake and 1XP8 001-2 rotary pulse encoder

H99

F01+F11+F70+G02

Mounting of brake, separately driven fan and 1XP8 001-2 rotary pulse

encoder

K02

L00

Vibration quantity level B

Balance and vibration quantity

K04

L08

Concentricity of shaft extension, coaxiality and linear movement in

accordance with DIN 42955 Tolerance R for flange-mounting motors

Shaft and rotor

K09

Position 16 of the

Order No., digit 5

Connection box on RHS

Motor connection and connection

boxes

K10

Position 16 of the

Order No., digit 6

Connection box on LHS

K11

Position 16 of the

Order No., digit 4

Connection box top, feet screwed on

K15

z

Connection box in cast-iron version

K16

L05

Second standard shaft extension

Shaft and rotor

K17

H23

Drive-end seal for flange-mounting motors with oil resistance to 0.1 bar

Mechanical design and degrees of

protection

K20

L22

Bearing design for increased cantilever forces

Bearings and lubrication

K23

S00

Unpainted (only cast-iron parts primed)

Colors and paint finish

K24

S01

Unpainted, only primed

© Siemens AG 2008