C7t\i – John Deere 60 User Manual

Page 5

D

60, 90, and 125 Skid-Steer

Loaders

30-200-5

Hydrostatic

Drive Operation-125

Loader

FLYWHEEL

SPLINED

MDUNTING

HUB

PLATE

/£1/

&~

'\

ENGINE

FLYWHEEL

HOUS

ING

CSM951

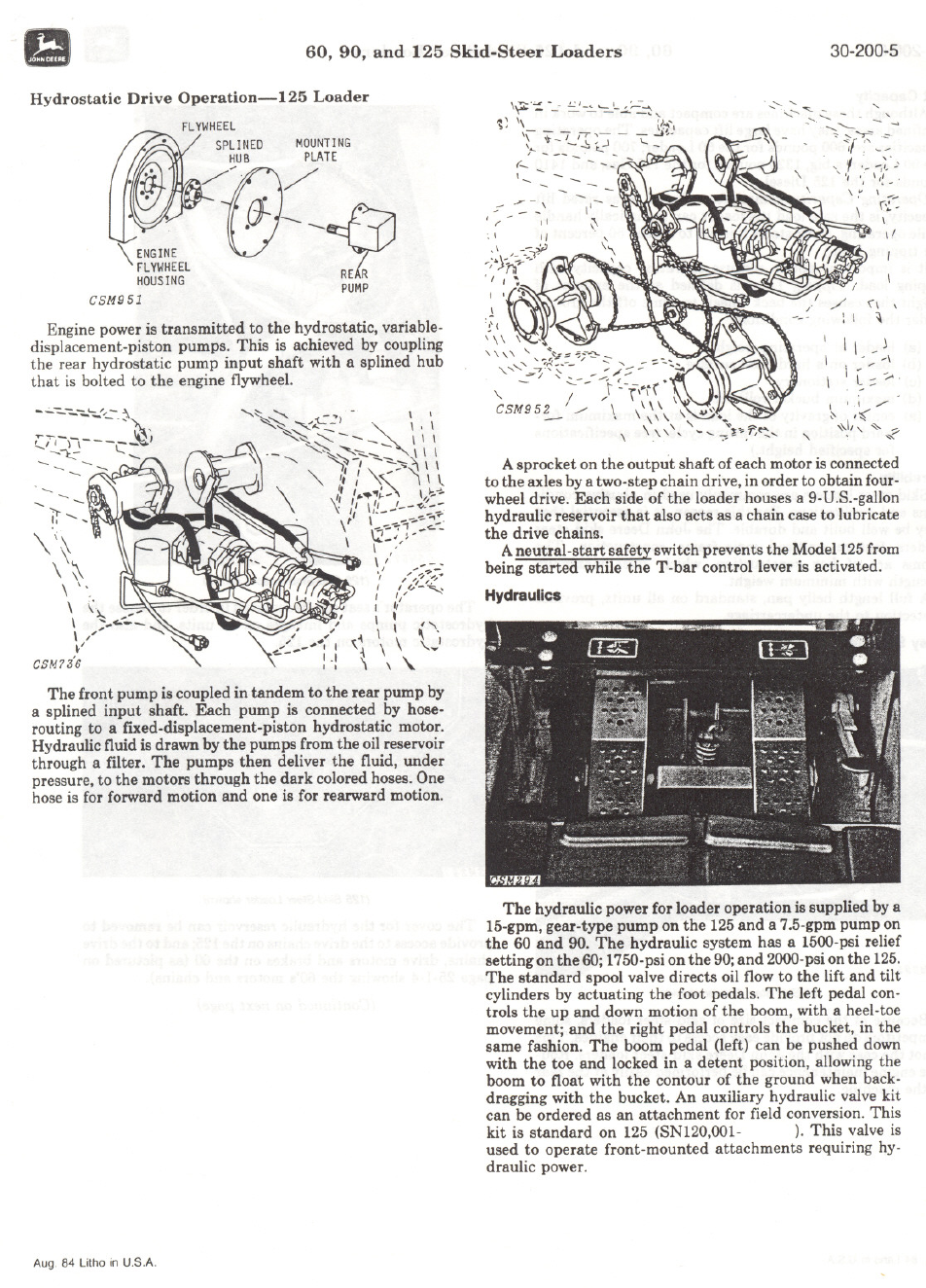

Engine power is transmitted to the hydrostatic, variable-

displacement-piston pumps. This is achieved by coupling

the rear hydrostatic pump input shaft with a splined hub

that is bolted to the engine flywheel.

PUMP

-

.;..

-:'.:~

- ...,

--.(.- -\

C7T\I---~~'

----"-:""

I

_~I

--

--

--

--

--

"'"

-..

-

\

I

"'-'::-: ,<1-

,

-)

~

\ ' \

,~

--:::::

----

\ \ \

~

z.'>"'--

--

\ \ \

\\

~-,--""::::...~~ \ \

"

I,' I "'

2\

--

"; \

~

"

I "

..

\

,. '.."~-

I,.?-

\'! "

\

I, I__~__-

~

'I

1.--

--,..

\

t

\ ---~ :-

\~- " . -~ -

\

t-:/

\ "

--,

/

, ~-

'/

I'I:"'~'

I

11,-""

I

'/

1

II

1

I

I

I

\

I,

'\'

-,.,'

~\

\

"I

/~__~', t

\

\

\..-

-

:'!

'\

\

\.

'

I

-../;--~

CSM73'S

The front pump is coupled in tandem to the rear pump by

a splined input shaft. Each pump is connected by hose-

routing to a fiXed-displacement-piston hydrostatic motor.

Hydraulic fluid is drawn by the pumps from the oil reservoir

through a filter. The pumps then deliver the fluid, under

pressure, to the motors through the dark colored hoses. One

hose is for forward motion and one is for rearward motion.

Aug, 84 Litho in U,S,A,

,~~

--' ==-,-~,,=-,-~~,

.'

"

i~""-,

"

- - - -,-

- - ..:t~.

't

~

- 1_/

it}

'--

,

- --

-

-

(--

--'I

'- -

',-"-

,-.. ""- ..

'

--- -

,

- ,--- -~

" ,'r'

y"

,:

, 'I . -;',

", ,;', :,' "

'"

\"

,

c..:-::

\

,I

.S' - ,

;:'

-..

II

'~(

\

\ \

""'-",

""

',_~"":"r-:::::::" -~-::.-:.-

",...' ..,.~'C~'-

'",;:::-

.,..

-"'/'

"

.

-

-- - \"---~'i

"

/..

\,1

"

CSM952

I

-'

\

,\~\

\~"'-

-

\,,', "--"!"'~~'

\

"

-',

(\

\

~

I I ,)

,

,\

I,

~~

~

,

I

'I

-'

~

.~

~I/,

~

.-

-<

A sprocket on the output shaft of each motor is connected

to the axles by a two-step chain drive, in order to obtain four-

wheel drive. Each side of the loader houses a 9-D.S.-gallon

hydraulic reservoir that also acts as a chain case to lubricate

the drive chains.

A neutral-start

safety switch prevents the Model 125 from

being started

while the T -bar control lever is activated.

Hydraulics

The hydraulic power for loader operation is supplied by a

15-gpm, gear-type pump on the 125and a 7.5-gpm pump on

the 60 and 90. The hydraulic system has a 1500-psi relief

setting on the 60; 1750-psion the 90;and 2000-psion the 125.

The standard spool valve directs oil flow to the lift and tilt

cylinders by actuating the foot pedals. The left pedal con-

trols the up and down motion of the boom, with a heel-toe

movement; and the right pedal controls the bucket, in the

same fashion. The boom pedal (left) can be pushed down

with the toe and locked in a detent position, allowing the

boom to float with the contour of the ground when back-

dragging with the bucket. An auxiliary hydraulic valve kit

can be ordered as an attachment for field conversion. This

kit is standard on 125 (SNI20,OOI-

). This valve is

used to operate front-mounted attachments requiring hy-

draulic power.