Blade guide bearing adjustment, Test cutting to verify adjustment accuracy, Figure 12: blade-to-blade guide orientation – Jet Tools J-7060 User Manual

Page 13

13

Blade Guide Bearing

Adjustment

Proper adjustment of the blade guide bearings is

critical to efficient operation of the cut-off saw. The

blade guide bearings are adjusted at the Factory.

They should rarely require adjustment. When

adjustment is required, adjust immediately. Failure to

maintain proper blade adjustment may cause serious

blade damage or inaccurate cuts.

It is always better to try a new blade when cutting

performance is poor. If performance remains poor

after changing the blade, make the necessary

adjustments.

If a new blade does not correct the problem,

check the blade guides for proper spacing. For most

efficient operation and maximum accuracy, provide

0.001 inch clearance between the blade and the

guide bearings. The bearings will still turn freely with

this clearance. If the clearance is incorrect, the

blade may track off the drive wheel.

CAUTION: CHECK THE BLADE TO MAKE SURE

THE WELDED SECTION IS THE SAME THICKNESS

AS THE REST OF THE BLADE. IF THE BLADE IS

THICKER AT THE WELD, THE GUIDE BEARINGS

MAY BE DAMAGED.

If required, adjust the guide bearings as follows:

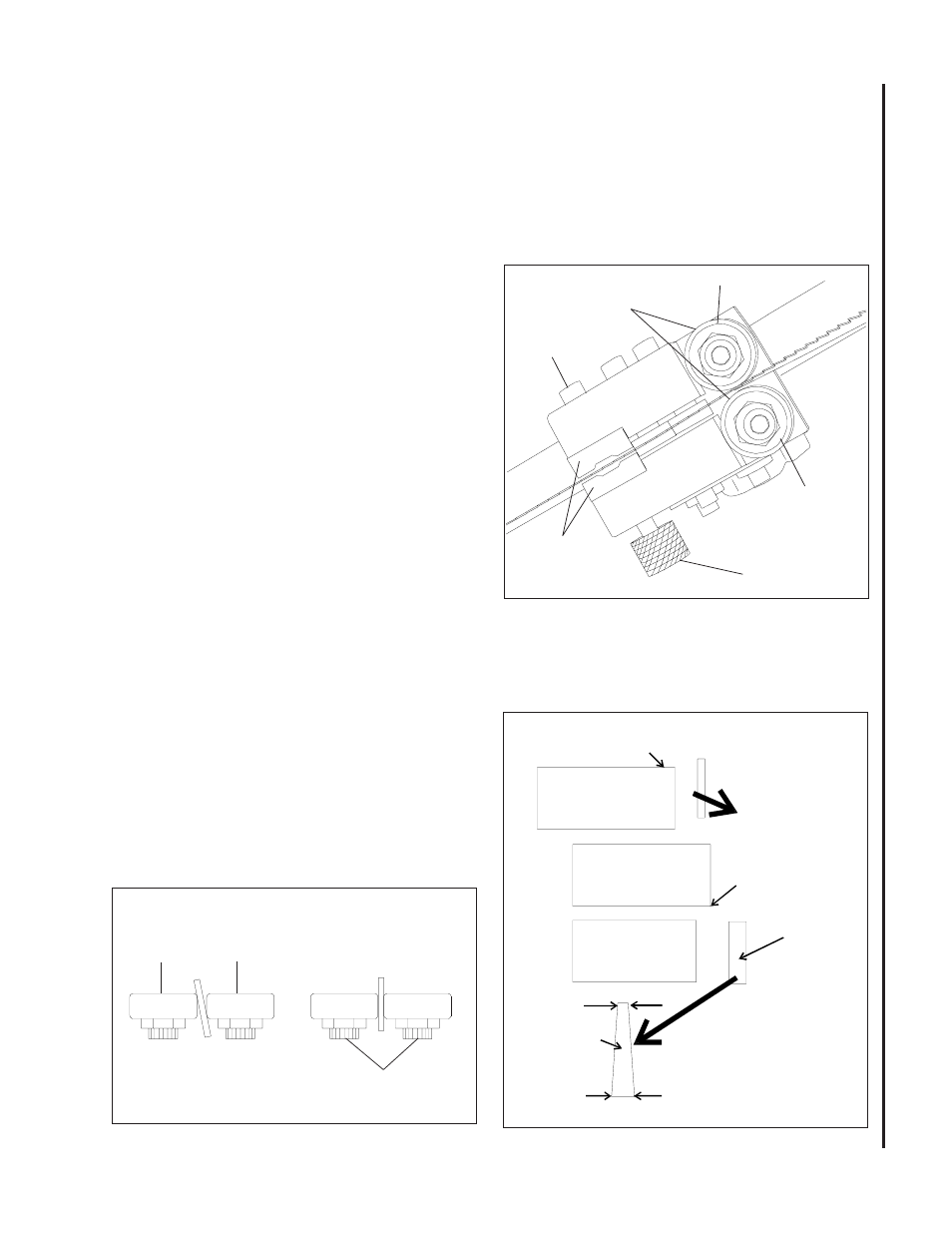

1. Two blade guides are used in each set of blade

guides. The inner blade guide is fixed; the outer

blade guide is adjustable. The outer blade guide

is adjusted using a knurled knob on the operator

side of the blade guide assembly.

2. A guide bearing is provided on the innermost

side of the saw blade. The guide bearing is

mounted on an eccentric bushing.

3. Hold the bushing with a 3/4-inch wrench and

loosen the center locking screw with an Allen

wrench (see figure 12).

4. Position the bearing by turning the bushing. Set

the clearance at approximately 0.001 inch.

Figure 12: Blade-To-Blade Guide Orientation

5. Tighten the center locking screw with an Allen 5.

5. Tighten the center locking screw with an Allen

wrench while holding the eccentric bushing in

position with the 3/4-inch wrench.

6. When the adjustment is correct, the guide

bearing should rotate freely with slight pressure

of the finger (with the blade stopped).

7. Adjust blade-edge bearings so they just touch

the back edge of the blade (see figure 19).

Figure 13: Adjustment of Guide Bearing

Figure 14: Cutting a Test

1. Clamp in vise and mark top

of barstock here

2. Cut off a slice of

the bar stock

3. Rotate stock in vise

so mark is at bottom

4. Cut off a new

slice from the

stock

5. Measure

here...

New slice

7. Differences between

measurements at edges

of disc should be less

than .003 inches per

inch per side of stock

diameter

6. ...measure

here

INCORRECT

CORRECT

Outer

Roller

Inner

Roller

Locking Screw

Concentric Bushing

Socket Cap Screw

Blade Guide

Bearings

Carbide

Guides

Knurled Knob

Eccentric

Bushing

Test Cutting to Verify

Adjustment Accuracy