Jet Tools 16-32 Plus User Manual

Page 24

24

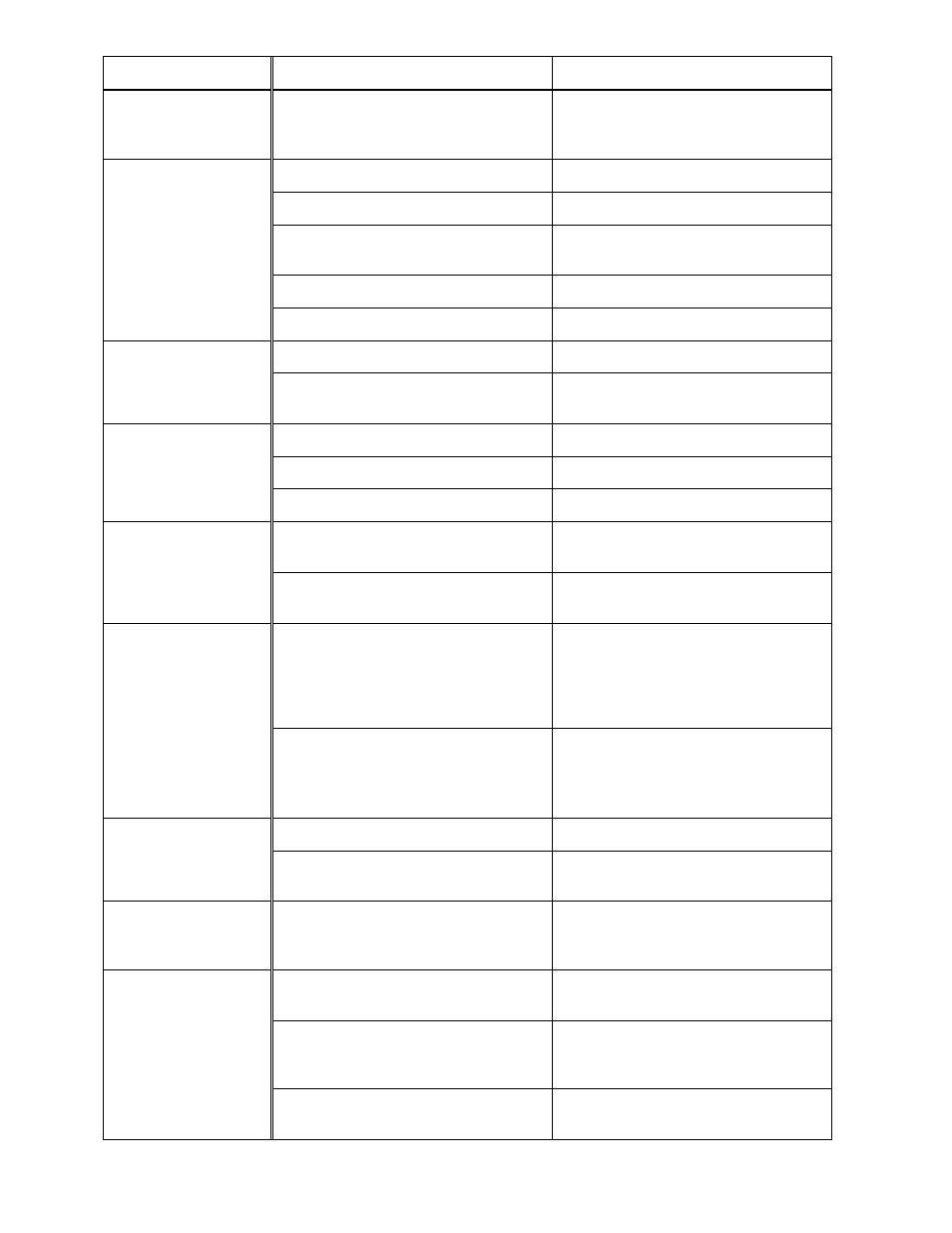

Trouble Probable

Cause

Remedy

Conveyor rollers run

intermittently.

Shaft coupling loose.

Align shaft flats of gear motor and

drive roller, and tighten shaft coupling

set screws.

Abrasive strip is overlapped.

Re-wrap abrasive strip (page 12-13)

Abrasive is loaded.

Clean abrasive.

Depth of cut excessive for fine grit.

Use coarser grit or reduce depth of

cut.

Feed rate too slow.

Increase feed rate.

Sander burns wood.

Abrasive is worn.

Replace abrasive.

Improper conveyor belt tension.

Adjust belt tension (page 16).

Conveyor belt slips

on drive roller.

Excessive depth of cut and/or feed

rate.

Reduce depth of cut and/or feed rate.

Tension rollers too high.

Lower tension rollers (see page 19).

Excessive feed rate.

Reduce feed rate.

Board slips on

conveyor belt.

Dirty or worn conveyor belt.

Replace conveyor belt.

Improper conveyor belt tension.

Adjust belt tension. If necessary,

reduce depth of cut and/or feed rate.

Sander motor slows

or stalls.

Excessive depth of cut and/or

excessive feed rate.

Reduce depth of cut or feed rate.

A. Uneven feed rate.

Conveyor belt slipping (see above)

Board slips on conveyor belt (see

above).

Conveyor motor stalls (see above).

Ripples in sanded

surface.

A. Non-uniformly

spaced ripples.

B. Uniformly spaced

ripples.

B. Conveyor bed flexing or vibration.

Reduce depth of cut and/or feed rate.

Check for loose bolts, loose shaft

coupling set screws, or out-of-balance

drum.

Stock slipping on conveyor.

Correct depth of cut or roller tension.

Wood is gouged.

Work piece not properly supported.

Add work supports for long work

pieces.

Table height

adjustment works

improperly.

Improper adjustment of height control.

Readjust height control. See pages

18-19.

Excessive load on sanding drum and

motor.

Allow motor to cool and re-set

overload button.

Too many tools on circuit.

Connect sander to a dedicated circuit.

Have a certified electrician correct

any shop wiring problem.

Motor overload

protector trips or

shop wiring breaker

trips.

Excessive length or inadequate size

extension cord.

Use a shorter or heavier gauge

extension cord (see Figure 19).