Sanding drum alignment – Jet Tools 16-32 Plus User Manual

Page 17

17

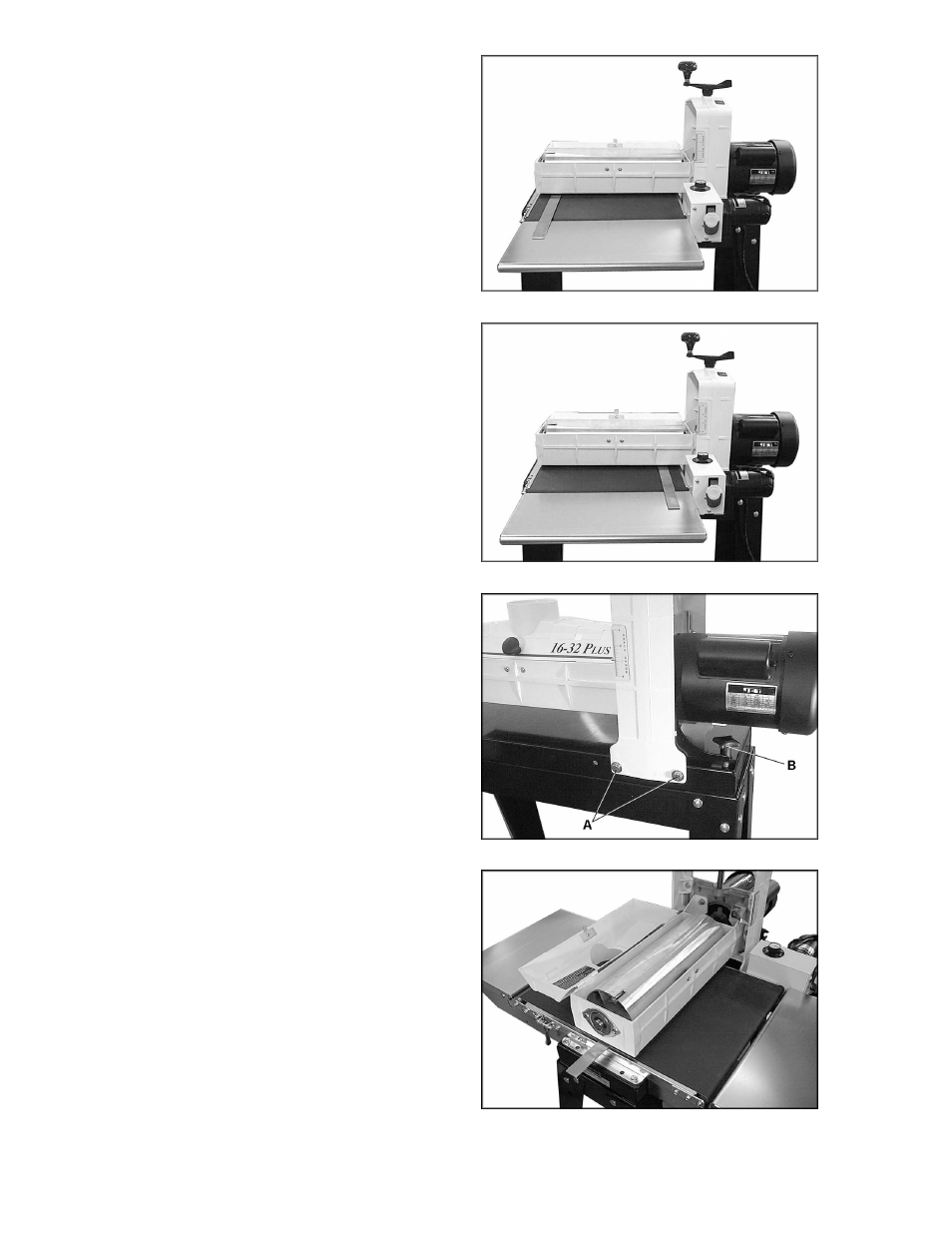

3. Remove the four bolts attaching conveyor

assembly to base. Lift up and slide conveyor

out to the side of the machine.

4. Set conveyor on motor side and slide

conveyor belt off the end of the conveyor

bed.

5. Reverse process for installation of new belt.

Sanding Drum Alignment

The sanding drum must be aligned parallel to

the conveyor bed for proper machine operation.

The sanding drum comes preset from the

factory. If a problem with the drum alignment

occurs, follow the instructions below.

First inspect the alignment with a gauge of some

kind. The following procedure uses a steel

straight edge as a gauge.

1. Unplug sander from power source.

2. Open the dust cover and remove the

abrasive strip from the drum.

3. Insert the gauge between the drum and

conveyor bed at the outer end of the drum

(Figure 23). With the dust cover open, lower

sanding drum while slowly rotating drum by

hand until the drum lightly contacts the

thickness gauge.

4. Remove thickness gauge and place under

drum at the other end (Figure 24). If the

drum does not contact the thickness gauge

to the same degree as the opposite end of

the drum, alignment is necessary.

To align the drum:

1. Loosen the four 3/8” hex cap screws – two

front, two rear (A, Figure 25). This allows the

entire drum carriage and shroud to be

pivoted on two screws – one screw in front,

one in back.

2. Lay the thickness gauge under the drum

lengthwise (Figure 26). Rotate the fine tune

adjustment knob (B, Figure 25) until the

drum contacts the gauge equally along its

entire surface. Rotate the knob clockwise to

raise the outboard end of the drum,

counterclockwise to lower the outboard end

of the drum. Use the height adjustment

handle to raise or lower the entire drum.

3. When drum is parallel to conveyor, tighten

the four screws (A, Figure 25).

Figure 23

Figure 24

Figure 25

Figure 26