Maintenance, Troubleshooting – Jet Tools 16-32 Plus User Manual

Page 23

23

Maintenance

Before doing maintenance on

the machine, disconnect it from the electrical

supply by pulling out the plug or switching

off the main switch! Failure to comply may

cause serious injury.

For best results, perform the following

recommended procedures on a monthly basis:

•

Lubricate conveyor bushings and check for

wear.

•

Lubricate all moving parts, such as threaded

rods, washers, and bushings. (Bearings are

pre-sealed and require no lubrication.)

•

Clean sawdust from the abrasive strip and

the conveyor belt.

•

Blow dust from motors and switches. Blow

dust from inside of sanding drum.

•

Check all set screws for tightness on parts

such as bearings, conveyor and couplings.

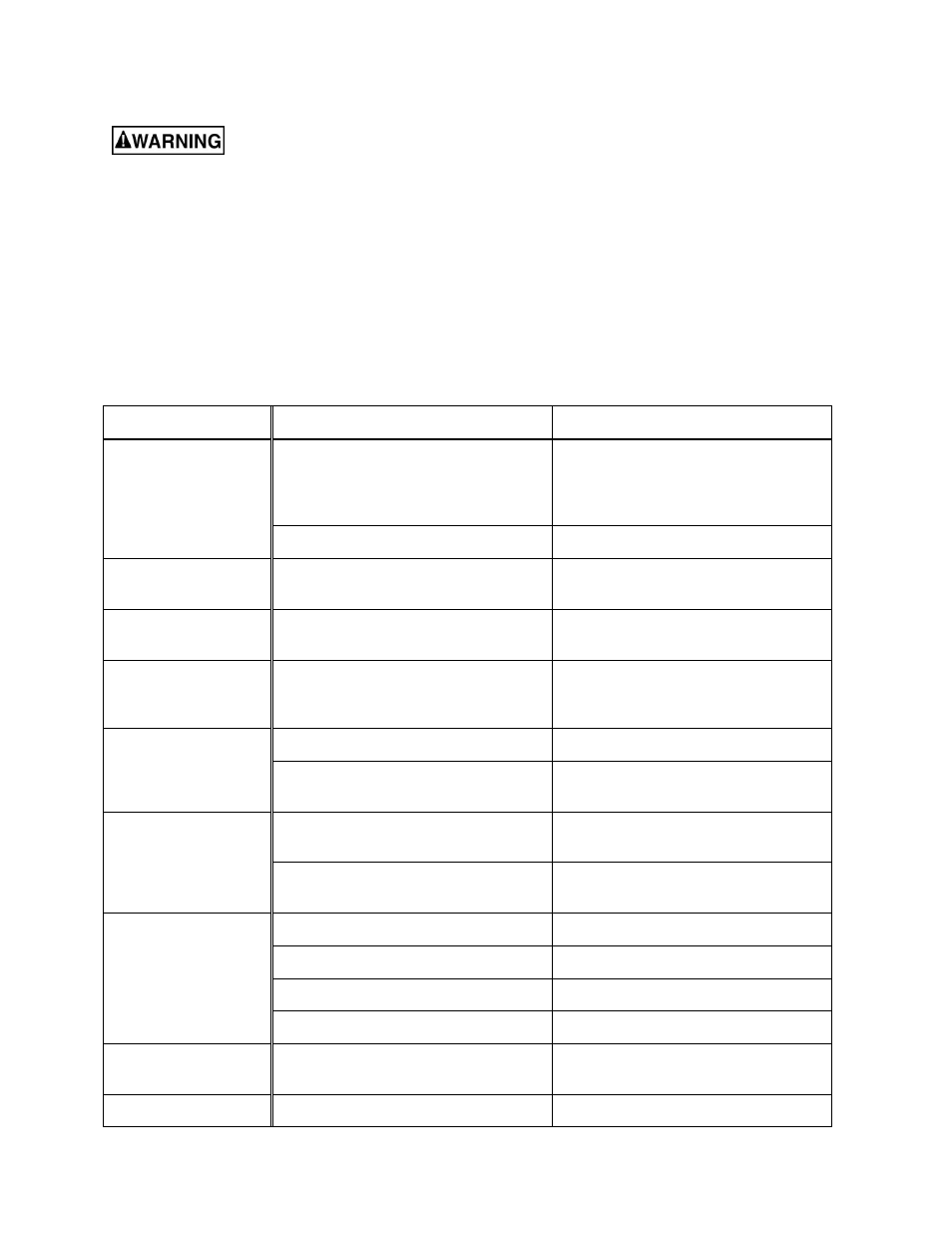

Troubleshooting

Trouble Probable

Cause

Remedy

No incoming power.

Check plug connection. Make sure

fuse is not blown/circuit breaker is not

tripped. Push the circuit breaker

button on the sander motor to re-set.

Sander will not start.

Switch is malfunctioning.

Replace switch.

Conveyor motor

stalls.

Excessive depth of cut.

Reduce depth of cut; use coarser grit;

reduce feed rate.

Conveyor belt does

not move.

Shaft coupler is loose or unattached.

Adjust shaft coupler.

Conveyor rollers run

intermittently.

Shaft coupling is loose.

Align the shaft flats of the gear motor

and the drive roller and tighten the

shaft-coupling setscrews.

Slack in abrasive strip on drum.

Remove slack in strip.

Abrasive strip comes

off drum.

Abrasive improperly wrapped.

Read the section on wrapping

abrasive strips, pages 12-13.

Strip caught on inside edge of slot, or

on inboard side of drum.

Re-adjust the strip end in the slot

and/or trim the abrasive edge.

Abrasive strip is

loose.

Strip not cut properly.

Re-cut and re-install the abrasive

strip.

Excessive depth of cut.

Reduce depth of cut.

Excessive feed rate.

Reduce feed rate.

Inadequate dust collection.

Increase airflow at dust port.

Abrasive loads up

prematurely.

Inadequate abrasive.

Use an open-coat abrasive.

Line or groove in

stock.

Inconsistent feed rate.

Do not stop or change the feed rate

while feeding stock.

Snipe marks.

Improper tension on rollers.

Re-tension rollers (see page 19).