Pulley alignment, Electrical connections – Jet Tools JWBS-18X-3 User Manual

Page 21

21

the motor.

The weight of the motor should put enough

tension on the belt. You just want to push down

lightly to take up any slack.

3. Tighten the two hex cap screws (A , B).

Note: A new belt may stretch slightly during the

“breaking in” process, and the tension may

occasionally need to be checked and adjusted.

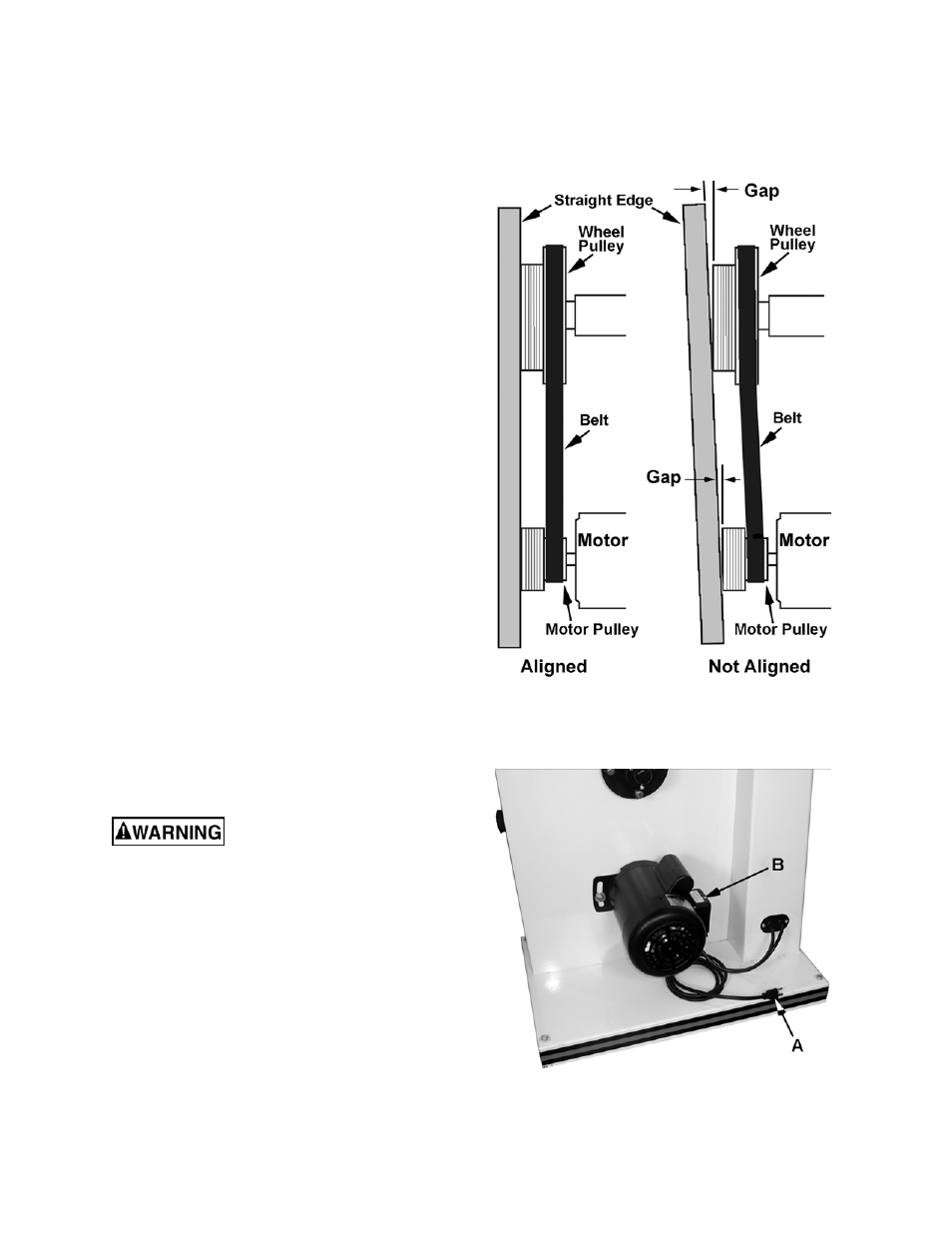

Pulley Alignment

The pulley alignment is done in conjunction with the

V-belt replacement.

If you are just beginning the alignment, start with

the Replacing the V-Belt section (previous page.

If you were directed here, proceed as follows:

1. Uses a straight edge placed against the wheel

pulley and motor pulley and refer to Figure 28

to determine if alignment is necessary.

If alignment is necessary:

2. With a 4mm hex wrench, loosen two set screws

on the motor (lower) pulley.

3. Adjust the motor pulley by sliding in or out.

4. Confirm the alignment of the V-belt by placing a

straight edge against the faces of both pulleys,

(Figure 28). If the straight edge lies flush

against both pulleys, then the pulleys and belt

are aligned.

5. Re-tighten the two set screws on the motor

pulley.

6. Return to Step 8 of the Replacing V-Belt

section on page 20.

Electrical Connections

All electrical connections must

be done by a qualified electrician. Failure to

comply may result in loss of property and/or

serious injury.

JWBS-18X is rated at 1.75 HP, 1Ph, 115/230V,

prewired 115V.

The band saw comes with a 115V plug (A, Fig. 29).

If you switch to 230V a plug needs to be purchased

for the band saw that matches the 230V outlet you

intend to use.

Confirm power at the site is the same as the saw

before making any electrical connections. Review

the wiring diagram on page 38.

Review Grounding Instructions on page 7.

Figure 28

Figure 29