ICI - Innovative Creations, Inc. AX User Manual

Page 9

ACCESSORIES

7

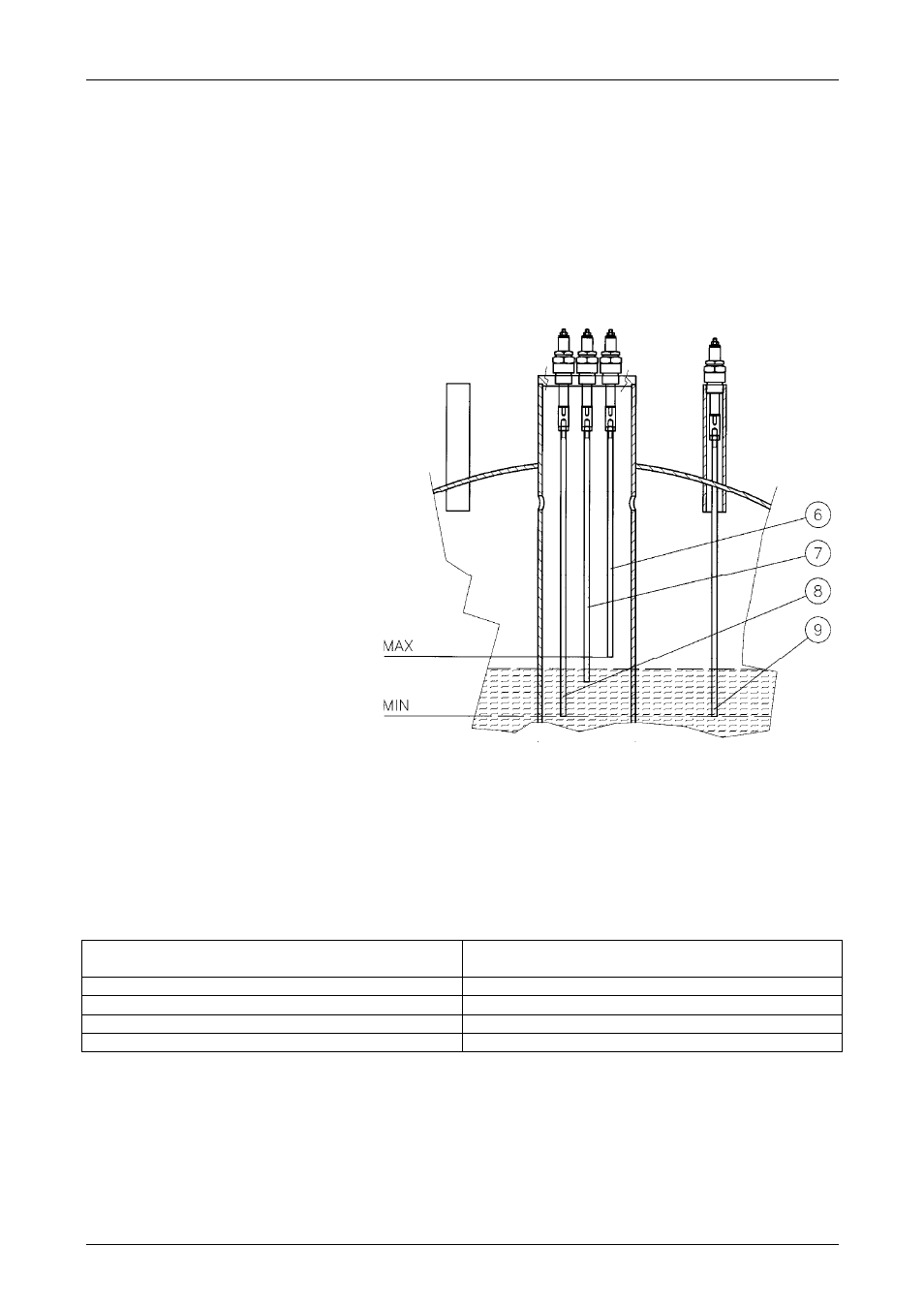

2.2.2 Automatic level regulator and water level limits (Fig. 7)

The physical principle employed to detect and control the water level is based on the electrical conductivity

of the water. The control device consists of a part sited in the control panel (electronic relays) and of probes

of differing lengths immersed in the boiler shell.

Operation of the system provides for:

• Automatic pump start and stop: Two probes inserted in the boiler, of which the longer starts, and the

shorter stops the pump, connected to a single control relay in the control panel.

• Burner stop at low water level: two probes of the same length, inserted in the boiler and connected to

two distinct control relays in the control panel, stop the burner permanently if the water level drops below

the admissible level.

Boiler probes:

6 Pump

stop

7 Pump

start

8 1

st

safety burner stop and alarm on.

9 2

nd

safety burner stop and alarm on.

N.B.: we suggest that as well as the

acoustic alarm in the boiler room, a

further acoustic alarm be provided in

an area where personnel is normally

present.

Fig. 7

2.3 FEED

WATER

An electric centrifugal pump supplies the water. The inlet side of the pump must never be under suction

pressure, but always under positive pressure due to the difference in height between the pump itself and the

feed water tank. While a pump can operate under suction head from a cold water tank (up to 5-6 m), if the

water is hot the pump cannot operate and indeed needs the water to be delivered under a certain pressure.

The height of the feed water tank varies with the temperature, as shown in the following table:

Feed water temperature

(Celsius)

Positive water head

(metres)

60 1

70 2

80 3

90 4,5

WARNING

• Avoid the use of feed water at temperatures lower than 60 Celsius, being rich in Oxygen and

therefore such as to cause corrosion.

• To avoid pump cavitation problems, the feed water temperature should not be higher than 90

Celsius.