Water characteristics, 6 water characteristics, Cc ca s 100 – ICI - Innovative Creations, Inc. AX User Manual

Page 16

WATER CHARACTERISTICS

14

6 WATER CHARACTERISTICS

For steam generators

with heating surface over 15 sqm, there are some regulations that require limit

values for water characteristics. These values are listed in the tables below.

However, limits should be adopted for all generators as stated by qualified companies that recommend the

type of treatment to be carried out basing on careful analysis of the available water. Many faults and

sometimes serious accidents are caused by the use of water with non-conforming features.

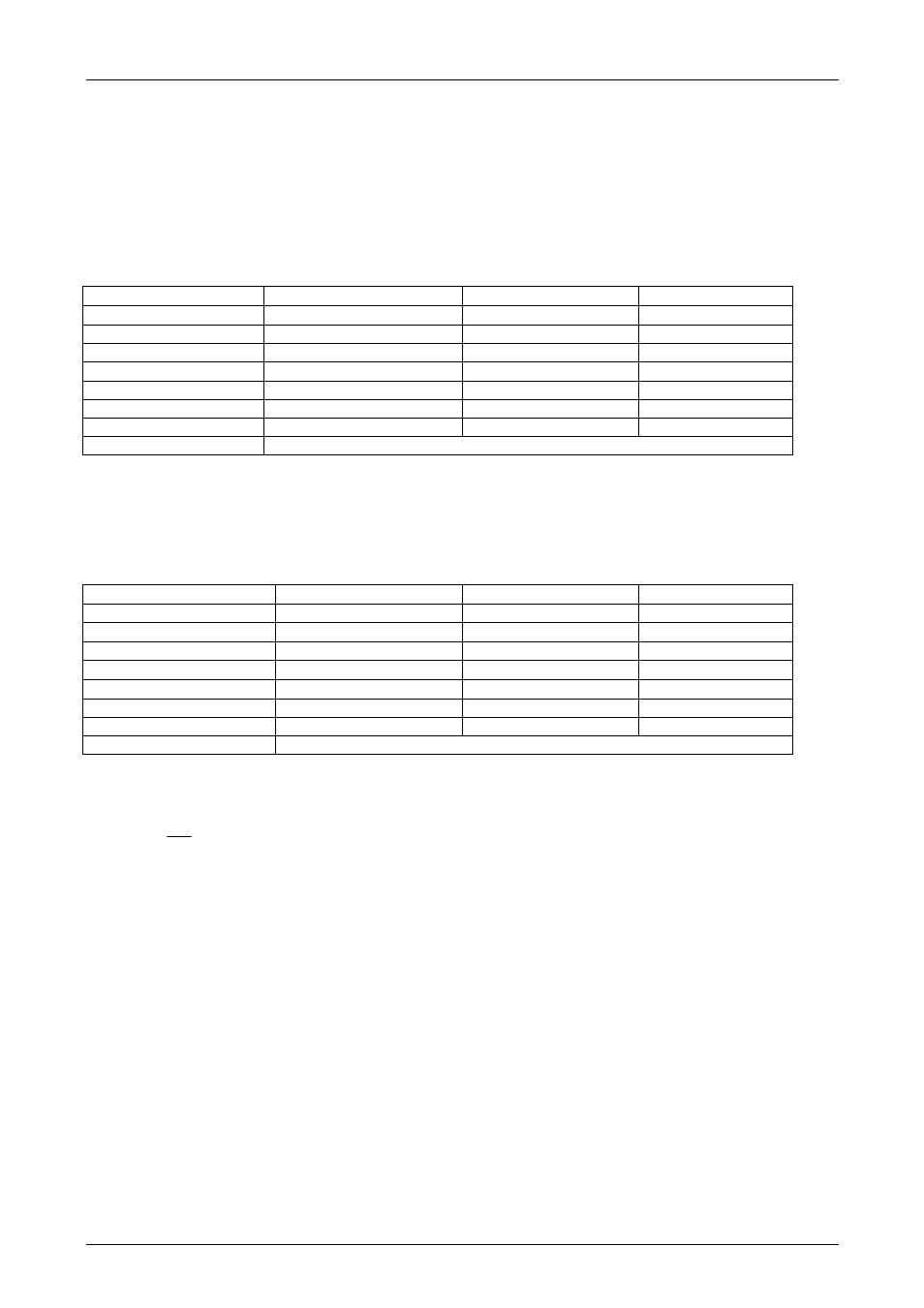

6.1 FEEDWATER - LIMIT VALUES (entering the boiler)

Tab.1

Characteristics

Unit of measurement

Pressure ≤ 15 bar

Pressure ≤ 25 bar

pH

7

$ 9,5

7 $ 9,5

Total hardness

mg/l CaCo

3

10 5

Oxygen (1)

mg/l O

2

0,1 0,05

Free Carbon Dioxide (1) mg/I CO

2

0,2

0.2

Iron mg/l

Fe

0,1

0,1

Copper mg/l

Cu

0,1 0.1

Oily substances

mg/I

1

1

Aspect

Clear, limpid, no persistent foam.

(1) These values are valid to have a thermo degassing device. Without degassing device, the temperature of the tank

water must be increased to at least 80 Celsius (see chapter 2.3. - Feeding) to reduce the content of dissolved

gasses (O

2

and CO

2

). Chemical deoxygenators must be used to remove completely the oxygen from the feed water

and reduce as much as possible CO

2

corrosive effects.

6.2 OPERATING WATER - LIMITING VALUES

Tab.2

Characteristics

Unit of measurement

Pressure ≤ 15 bar

Pressure ≤ 25 bar

pH

9

$ 11

9 $ 11

Total alkalinity

mg/l CaCo

3

1000 750

Total hardness

mg/l CaCo

3

10 5

Maximum conductivity (4)

µS/cm

8000 7000

Silica

mg/l SiO

2

150

100

STD (4)

mg/l

3500

3000

Conditioner (2)

Aspect

Clear, limpid, no persistent foam

(1) To maintain in the boiler the parameters of alkalinity and silica within the prescribed or recommended limits, the boiler

must be purged, if possible continuously. The values of the concentrations in the feedwater and in the boiler water are

linked to the continuous purge by the following relationship:

Cc

Ca

S

100

%

=

Where

S% = Percentage of purge with respect to the feed water supplied to the boiler;

Ca

= Real concentration of a certain salt or ion in the feed water

Cc

= Maximum allowed concentration in the boiler for the same salt.

(2) Correct management presupposes normally the use of conditioners, whose dosages and limits are in relation to the

nature and characteristics of the additives themselves.

(3) Determined on a filtered sample

(4) The two parameters have the same physical meaning but the values can be correlated only if the chemical

composition of the water is known.

6.3 FREQUENCY OF THE ANALYSES

The frequency of analysis is determined evidently as a function of the use of the boiler and of the quality of

the water used; it is advisable in any case to check the pH, the total hardness and the alkalinity of the feed

and boiler waters at least every two days. Once a month, especially under conditions of variable operation, it

is advisable to subject meaningful samples of the boiler and feed waters to complete analysis.

It is also advisable to inspect the return condensate for traces of any highly contaminating oily substances

(reduction of evaporation from the water surface in the boiler caused by a layer of oil).