Troubleshooting, 7 troubleshooting – ICI - Innovative Creations, Inc. AX User Manual

Page 17

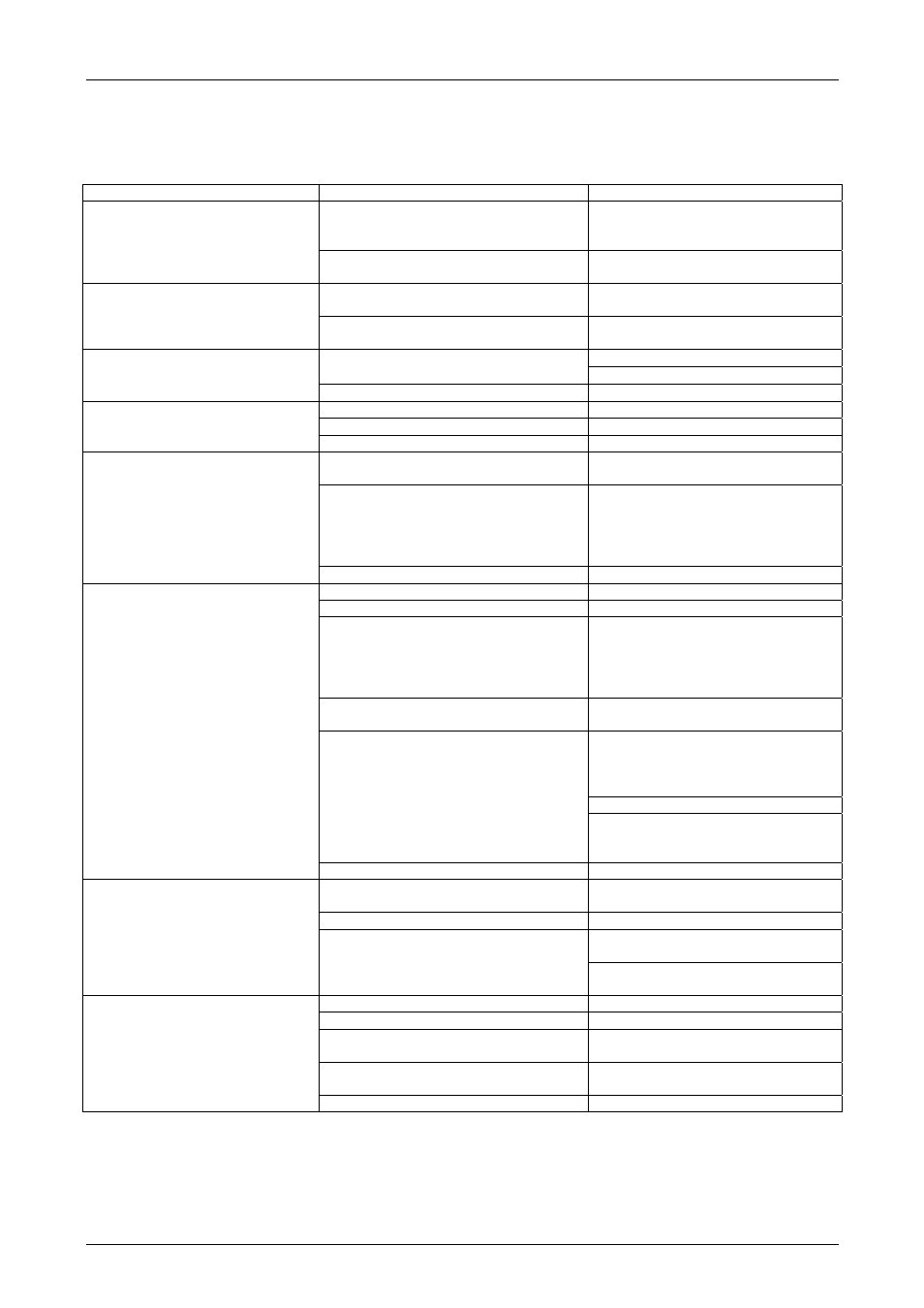

TROUBLESHOOTING

15

7 TROUBLESHOOTING

FAULT

PROBABLE CAUSE

SUGGESTED REMEDY

Maximum pressure exceeded, as set on

the valve. Must be equal to the boiler

design pressure.

Adjust the safety pressure switches

and / or limit switches.

Safety valve/s opening

Loss of the adjustment of the safety valve Check and then adjust the valve using

a reference gauge

Dirt on the valve seat

Clean the seat by opening the valve

manually a few times

Small leaks from the safety

valve/s

Marks on the valve seat

Dismantle the valve and regrind the

valve seat with very fine abrasive.

Check the motor current

Pump overload relay has acted

Check the relay setting

Pump stopped

Pump shaft seized

Maintenance to the pump

Pressure limit switch set too high

Adjust the pressure limit switch

Pressure limit switch faulty

Replace the pressure limit switch

Pressure safety switch operates

Pressure switch pipe coil blocked

Clean or replace the pipe coil

Water level detection interrupted

Steel probe encrusted

Connection cable interrupted

Safety level relay faulty

Temporary replacement of the safety

electronic relay with one of the two

relays in the panel.

If the problem disappears, replace the

faulty relay.

Safety level 1 or 2 operates

No water feed

See faults "feed water"

Pump seized

See faults "Pump stopped"

Pump suction filter blocked

Clean the filter

Level control faulty

Temporary replacement of the

electronic control relay with one of

those present in the panel.

If the problem disappears, replace the

faulty relay.

Level probes short circuited

Dismantle the control probes for

inspection of the ceramic insulation

Suction head (difference in height

between supply tank and pump)

insufficient in relation to the water

temperature

Clean the pump suction filter

Pump cavitation

Reduce the head loss in the pipe

between collector tank and the pump

by increasing the pipe section

Feed water insufficient

Pump rotation direction

Invert two phases (three-phase pump)

Erroneous electrical connection to the

panel

Consult the wiring diagram

Safety level relays faulty

See “Intervention safety level 1 or 2”

Check the adjustment of the pressure

switches

Burner always ON

Control and/or safety pressure switches

inactive

Check the pressure switch connections

to the control panel

Problems with the burner

See the specific burner Manual

Burner fuses interrupted

Replace the fuses

No consent to the burner from the control

pressure switch

Replace the control pressure switch

No consent to the burner from the safety

level relay

See “Intervention safety level 1 or 2”

Burner always OFF

Erroneous connection to the control panel Consult the wiring diagram