Troubleshooting, Continuous flow icemaker service manual – Cornelius WCF1411-A User Manual

Page 20

Continuous Flow Icemaker Service Manual

Publication Number: 630460324SER

- 16 -

© 2006, IMI Cornelius Inc.

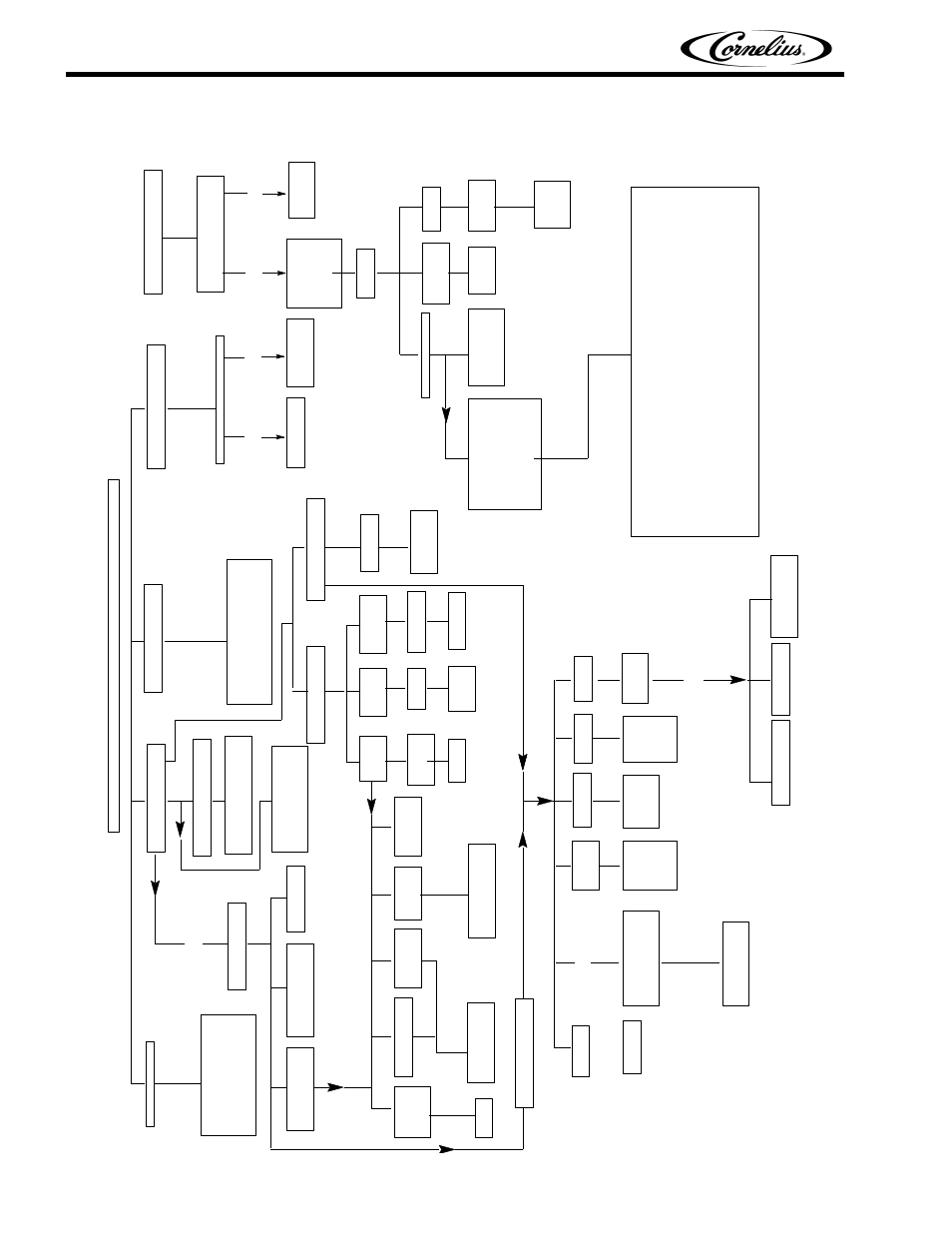

TROUBLESHOOTING

TR

OUBLESHOO

TING

CHAR

T

-

ICEMAKER

NO

T

OPERA

TING

NO

PO

WER

Chec

k

e

lectr

ical

wir

ing

in

c

on

trol

b

o

x

fo

r

loose

c

onnec

tions

.

Chec

k

for

fa

iled

s

er

vice

s

w

itch

or

rela

y.

Chec

k

p

o

w

er

to

machine

.

ICEMAKER

R

UNS

B

UT

DOES

NO

T

MAKE

ICE

Condenser

fan

ru

nning

b

u

t

c

ompressor

n

ot

ru

nning

Chec

k

line

v

oltage

.

Chec

k

c

ompressor

w

inding

&

c

omponents

.

LO

W

W

A

T

ER

SAFETY

SWITCH

OPEN

Remote

condenser

not

running.

Ev

apor

ator

w

a

ter

tube

ma

y

h

a

v

e

a

n

a

ir

b

u

b

b

le

.

Clear

a

ir

b

u

b

b

le

from

tube

.

Chec

k

p

o

w

er

to

condenser

.

Chec

k

e

lectr

ical

wir

ing

in

control

b

o

x

fo

r

loose

connections

.

High

pressure

s

w

itch

open

or

cycling

on

and

o

ff

.

Chec

k

that

w

ater

is

tur

ned

on.

Chec

k

for

restr

iction

in

w

a

ter

line

.

Chec

k

incoming

w

ater

pressure

(minim

um

10

lbs

.).

Chec

k

w

ater

saf

ety

s

witch.

ICEMAKER

OPERA

TING

B

U

T

SOFT

ICE

Chec

k

bin

s

witch

Clean

all

related

dr

ain

lines

.

Ref

er

to

guide

to

Good

Ice

in

ser

vice

man

ual.

GEARMO

T

O

R

O

VERLO

AD

TRIPPED

Chec

k

w

ater

le

v

e

l

c

ontrol

and

e

v

apor

ator

w

ater

tube

fo

r

lime

b

uild

up

restr

iction.

CA

UTION

Clear

ice

from

e

v

apor

ator

and

auger

bef

ore

re

setting

o

v

er

load.

CLEAN

see

instr

uctions

.

Reset

o

v

er

load.

Icemak

er

runs

Reset

b

ut

motor

does

not

run.

Will

not

reset.

Ov

er

load

hot

tr

y

again.

Will

not

reset

replace

o

v

er

load

Chec

k

gear

motor

circuit.

Shor

t

run

tr

ips

again

in

2

min

utes

.

Chec

k

gear

motor

circuit.

IMPOR

T

ANT

Icemak

er

runs

when

reset

b

u

t

prob

lem

has

not

been

found.

Contin

ue

chec

king

fo

r

o

v

er

load

as

follo

ws

to

guard

against

future

prob

lems

Lo

w

suction

pressure

(20

lbs

.

o

r

belo

w).

TXV

b

ulb

lost

charge

.

Replace

v

alv

e

e

v

acuate

and

recharge

.

High

suction

p

ressure

(30

lbs

.

o

r

a

bo

v

e

).

Suction

line

not

insulated.

Bulb

uninsulated.

Clean

and

insulate

.

TXV

n

ot

oper

ating

proper

ly

.

Bulb

loose

.

Clean

and

tighten.

Head

Pressure

high.

V

a

lv

e

stuc

k

open.

Replace

va

lv

e

.

Condenser

dir

ty

o

r

restr

icted.

Condenser

fa

n

n

o

t

running.

To

o

m

u

c

h

refr

iger

ant

in

system.

Non-condensib

le

in

system.

Discharge

king

v

alv

e

par

tially

closed.

Open

va

lv

e

Ev

acuate

a

nd

recharge

system.

Clean

c

ondenser

.

Chec

k

e

lectr

ical

circuit

to

fa

n

m

otor

.

Chec

k

fan

motor

.

Lo

w

p

ressure

s

witch

open

or

cycling

on

and

o

ff

.

Lo

w

o

n

refr

iger

ant.

Plugged

liquid

line

dr

y

e

r.

Restr

icted

liquid

line

.

Plugged

or

faulty

TXV

.

Icemak

e

r

froz

e

up

.

Chec

k

if

auger

is

tur

n

ing.

Replace

va

lv

e

.

Ev

acuate

and

recharge

system.

Chec

k

for

kinks

or

damage

to

liquid

line

.

Replace

dr

y

e

r.

Ev

acuate

and

recharge

system.

LA

C

n

ot

oper

ating

proper

ly

(minim

u

m

discharge

pressure

180

lbs

.).

Chec

k

for

leaks

.

Replace

L

A

C

v

a

lv

e

,

e

v

acuate

and

recharge

system.

Chec

k

d

ri

v

e

on

gear

motor

.

Chec

k

g

ears

in

gearbo

x.

Chec

k

if

e

xtr

uding

head

is

do

wn

in

e

v

apor

ator

tube

.

O

V

ERLO

A

D

GUIDE

ELECTRICAL

High

or

lo

w

v

oltage

w

eak

po

w

e

r

lines

can

cause

o

v

er

loads

on

icemak

er

restar

ts

High

running

current.

Chec

k

motor

circuits

and

star

t

rela

y

-

A

uger

dela

y

failed.

ICEMAKER

Mechanical

p

ar

ts

w

o

rn

.

Scored

e

v

apor

ator

or

auger

.W

or

n

thr

ust

bear

ing.

Ice

mak

e

r

not

tur

ning

off

.

F

ailed

ice

le

v

e

l

control.

Ov

er

compression.

Lo

w

w

ater

inlet

temper

ature

.

R

estr

iction

in

w

ater

line

from

reser

v

oir

.

REFRIGERANT

Contaminated

charge

or

bad

compressor

.

Lo

w

charge

or

gas

leak.

Lo

w

suction

pressure

.

Improper

e

xpansion

v

alv

e

s

ensing

b

ulb

.

L

ocation

or

insulation

and/or

def

ectiv

e

e

xpansion

v

alv

e

No

Remote

condenser

units

only

Remote

condenser

units

only

No

Ye

s

Ye

s

No