Section 6 − maintenance and troubleshooting, 1. routine maintenance, 2. blowing out inside of unit – Miller Electric Maxstar 200 STR User Manual

Page 30: See section 5-5, See section 5-6, 4. stick start procedure − scratch start technique, 5. amperage control, 6. dig control

OM-2233 Page 24

5-4.

Stick Start Procedure − Scratch Start Technique

With Stick selected, start arc as follows:

1

Electrode

2

Workpiece

3

Arc

Drag electrode across workpiece like strik-

ing a match; lift electrode slightly after touch-

ing work. If arc goes out electrode was lifted

to high. If electrode sticks to workpiece, use

a quick twist to free it.

Y For models with stock number 907

220, normal open-circuit voltage (80

volts) is present before electrode

touches workpiece.

For models with stock numbers 907 036 and

907 037, normal open-circuit voltage is not

present before electrode touches work-

piece; only a low sensing voltage is present

between electrode and workpiece.

1

2

3

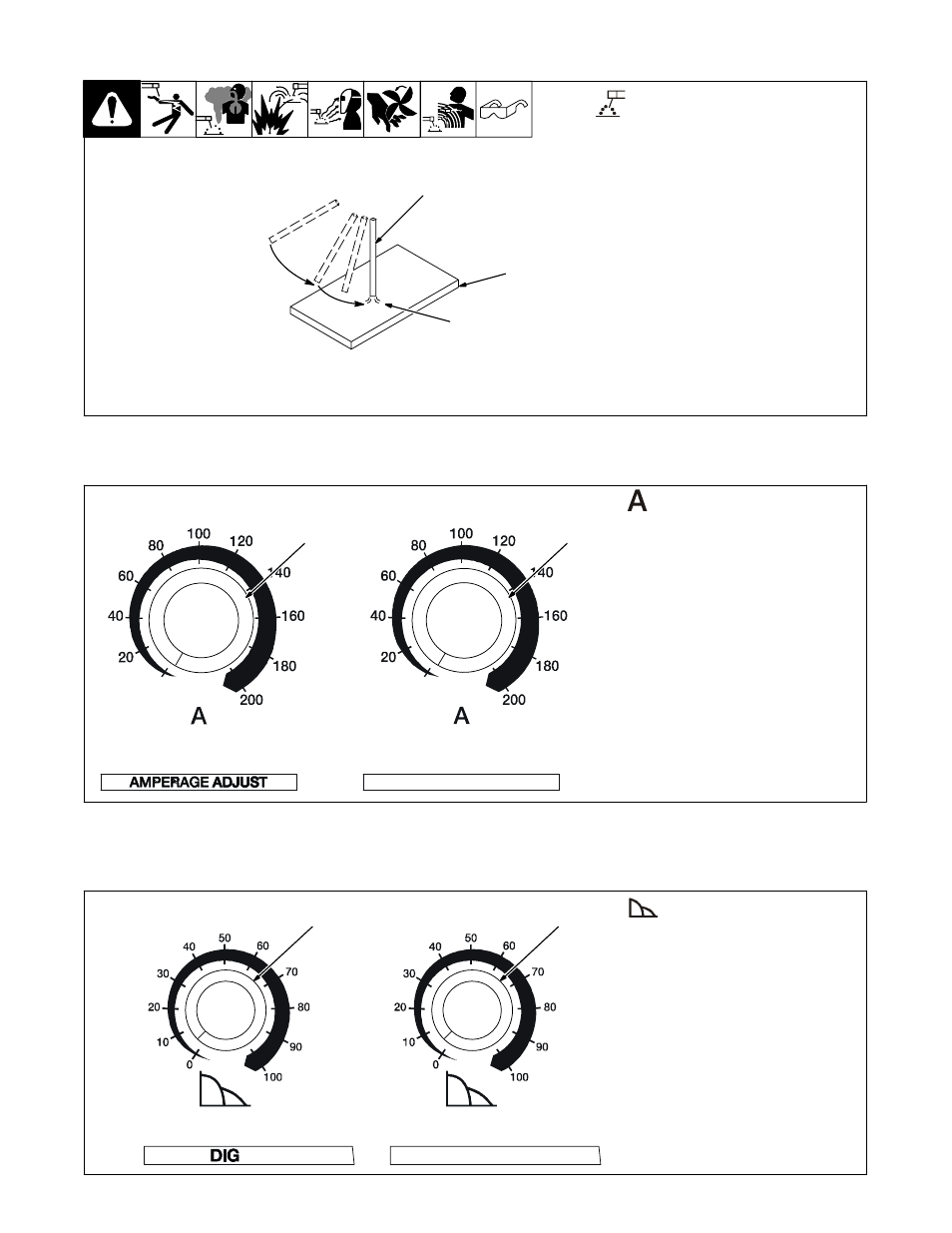

5-5. Amperage Control

1

A (Amperage Control)

Rotate knob clockwise to increase

amperage (Min-200 amps).

1

Min

CE Model

1

Min

5-6. DIG Control

1

DIG Control

Control increases SMAW short-cir-

cuit amperage at low arc voltage.

This allows the operator to use a

very short arc length without stick-

ing the electrode.

Set control at 0 for normal welding

amperage. Turn clockwise to in-

crease short-circuit amperage.

1

CE Model

1