Miller Electric Maxstar 200 STR User Manual

Page 23

OM-2233 Page 17

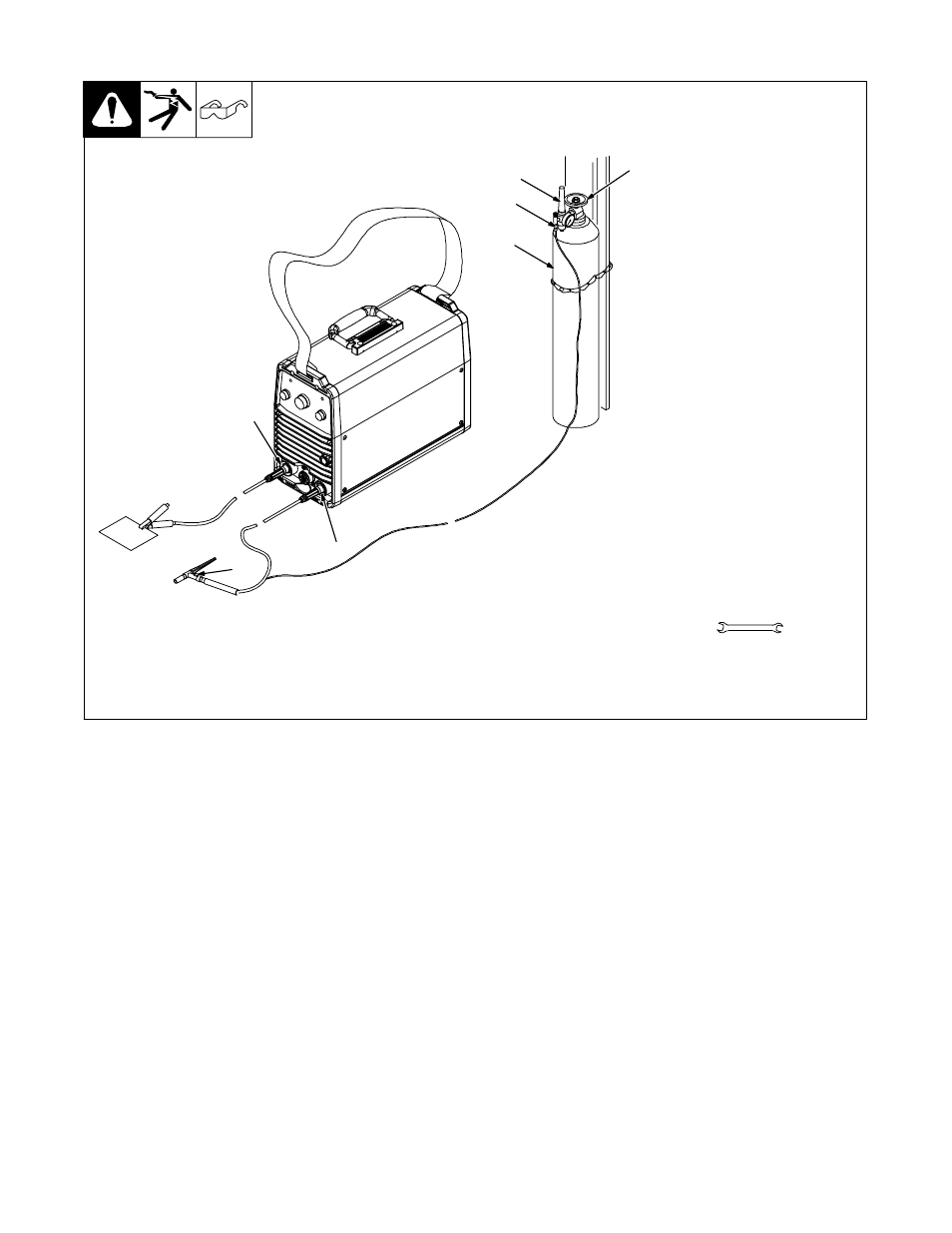

4-7. TIG Lift-Arc DCEN (Direct Current Electrode Negative) Connections

Ref. 802 888-A

Y Turn off power before mak-

ing connections.

1

Positive (+) Weld Output

Terminal

Connect work lead to positive weld

output terminal.

2

Negative (−) Weld Output

Terminal

Connect TIG torch to negative weld

output terminal.

3

Gas Cylinder

4

Cylinder Valve

Open valve slightly so gas flow

blows dirt from valve. Close valve.

5

Regulator/Flowmeter

6

Flow Adjust

Typical flow rate is 15 cubic feet per

hour (7.1 liters per minute).

Connect torch gas hose to regula-

tor/flowmeter.

7

Gas Valve

Valve controls gas preflow and

postflow. Open valve on torch just

before welding.

Tools Needed:

11/16 in, 1-1/8 in, (21 mm)

2

1

3

4

5

6

7

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)