9. electrical service guide – Miller Electric Maxstar 200 STR User Manual

Page 24

OM-2233 Page 18

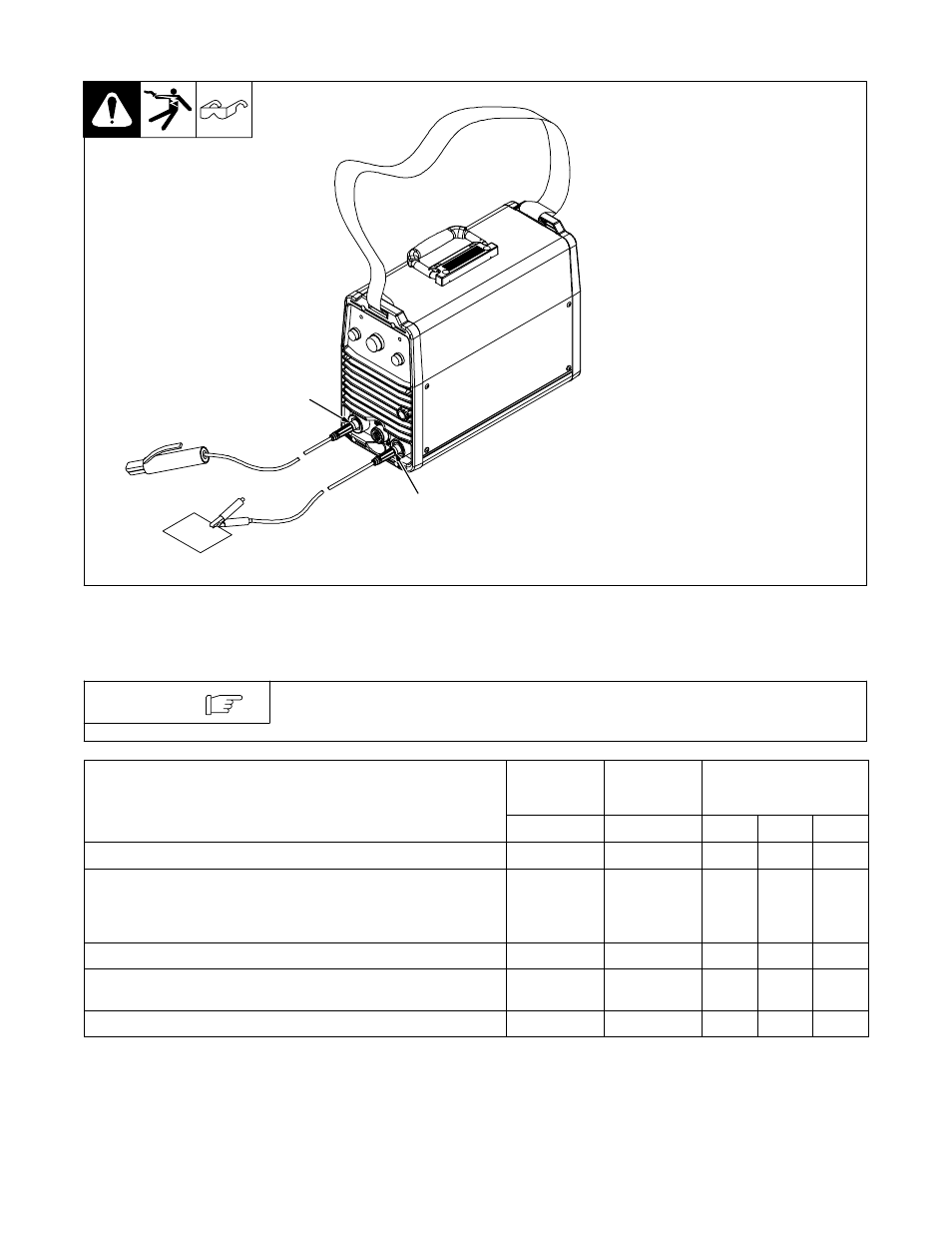

4-8. Stick DCEP (Direct Current Electrode Positive) Connections

Ref. 802 888-A

Y Turn off power before mak-

ing connections.

1

Negative (−) Weld Output

Terminal

Connect work lead to negative weld

output terminal.

2

Positive (+) Weld Output

Terminal

Connect electrode holder to posi-

tive weld output terminal.

1

2

4-9. Electrical Service Guide

Actual input voltage cannot exceed - 10% of minimum or +10% of maximum input

voltages indicated in table.

NOTE

Single-Phase,

100% Duty

Cycle

Single-Phase,

60% Duty

Cycle

Three-Phase, 60% Duty

Cycle

Input Voltage

115

230

230

400

460

Input Amperes At Rated Output

25

22

13.1

7.4

6.4

Max Recommended Standard Fuse Rating In Amperes

1

Time Delay

2

25

25

15

8

8

Normal Operating

3

35

30

20

10

10

Min Input Conductor Size In AWG

4

10

12

14

14

14

Max Recommended Input Conductor Length

In Feet (Meters)

57 (17)

79 (24)

102

(31)

308

(94)

407

(124)

Min Grounding Conductor Size In AWG

4

10

12

14

14

14

Reference: 2005 National Electrical Code (NEC)

1 If a circuit breaker is used in place of a fuse, choose a circuit breaker with time-current curves comparable to the recommended fuse.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.