Robot calibration mode, 5. robot calibration mode – Miller Electric Auto-Axcess 450 User Manual

Page 31

OM-210 540 Page 27

4-5.

Robot Calibration Mode

198 993

Use the robot calibration mode to

custom-calibrate the power source to

the robot command signals. This

ensures the wire speed, voltage, and

arc adjust are the same on the robot

pendant as on the power source.

.

The factory recommendation is to

perform the calibration on all

installations or code updates.

Follow this procedure if the factory

settings are not as accurate as

desired. Synchronization of the robot

and power source signals makes

installation easier and improves the

operation of the system.

.

The robot pendant must have

Weld enabled, and there can be

no start/stop crater conditions set

in the robot.

The calibration mode will execute as a

”dry run” from the operator’s

perspective. The welding power

source provides the robot with

feedback so the robot thinks a weld is

underway, yet the robot torch need not

move during the calibration.

.

If you wish to stop the calibration

procedure, turn unit input power

off and then on again.

If the calibration is performed correctly

the ROBT CAL message stops being

displayed; however, if it is performed

incorrectly, the message remains on

the display.

To start the calibration procedure over

again, turn unit input power off and

then on again following the calibration

setup steps following the calibration

setup steps.

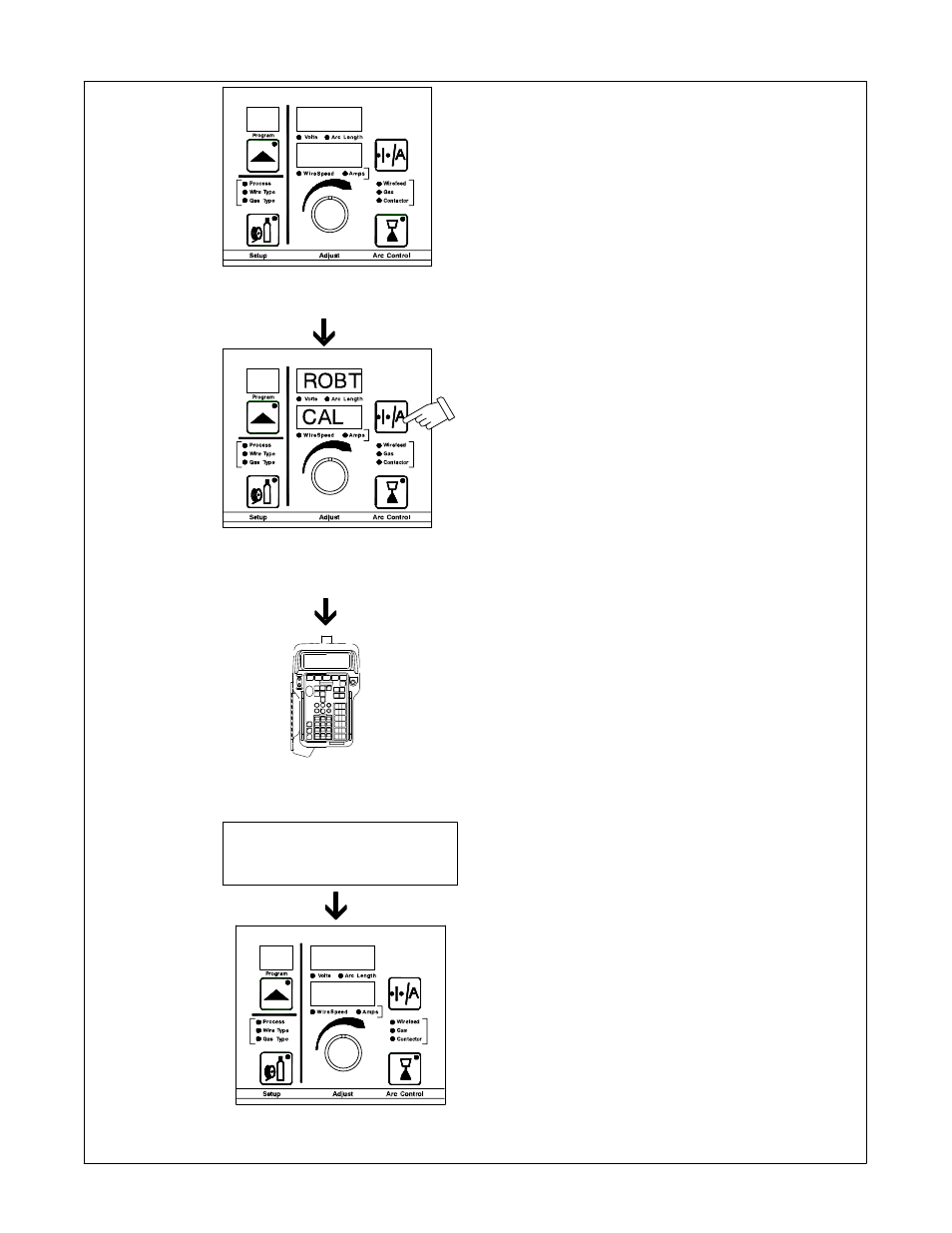

Turn unit On. Unit displays abbreviated name of robot

detected where XXXX appears (see Table 4-2 for a list

of robot adapters that could be displayed).

To enter calibration mode while robot name appears on front panel,

press and hold wire feed/amps button until “ROBT CAL” appears on

front panel. “ROBT CAL” message will not display until after the

power-up sequence is completed (approximately 20 seconds).

Use robot pendant or other method to enter two weld schedules into the

robot. Maintain schedule 1 for at least 10 to 20 seconds minimum before

moving on to schedule 2. Maintain schedule 2 for 10 to 20 seconds

before ending the simulated weld. Schedule data is shown below:

Schedule 1

10.0 Volts

100 IPM

Schedule 2

44.0 Volts

1000 IPM

When the robot calibration mode ends, the ROBT CAL message

stops and the unit will display normal front panel information.

CIRCULER

XXXX