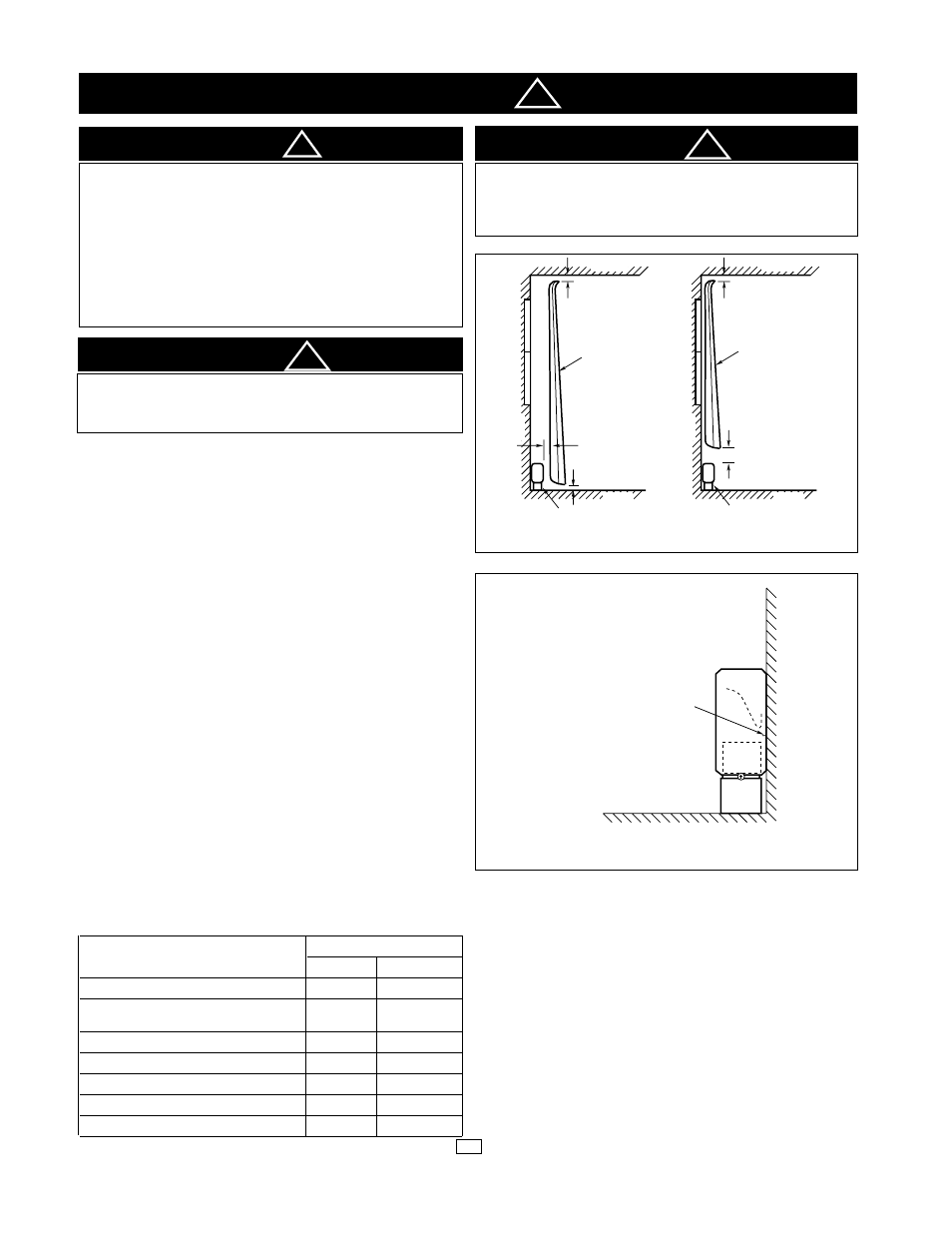

Important, Caution, Figure 1. positioning drapery near heater – Marley Engineered Products D User Manual

Page 2: Figure 2. installation of heater

CERTAIN FABRICS DISCOLOR IN TIME FROM INDIRECT SUNLIGHT AND

NORMAL ROOM TEMPERATURE - MOSTLY ORGANIC AND SYNTHETIC

MATERIAL. THEY WILL DISCOLOR MORE RAPIDLY WHEN EXPOSED TO

DIRECT SUNLIGHT AND WARM CURRENTS. HANG DRAPES TO PROVIDE

MINIMUM OF 2 INCHES (51mm) AIR SPACE BETWEEN HEATER FRONT

AND NEAREST DRAPE FOLD AS SHOWN IN EXAMPLE 1, FIGURE 1, OR 6

INCHES (152mm) AIR SPACE BETWEEN TOP OF HEATER AND BOTTOM

OF DRAPES AS SHOWN IN EXAMPLE 2, FIGURE 1. ALLOW MINIMUM

CLEARANCE OF 1 INCH (25mm) FROM DRAPES TO CEILING AND TO TOP

OF FLOOR COVERING TO PERMIT AIR CIRCULATION.

CLEARANCES

FLOORS & CARPETING: HEATERS MAY BE MOUNTED DIRECTLY ON ANY

FLOOR SURFACE, INCLUDING CARPETING. WHERE WALL-TO-WALL CAR-

PETS ARE INSTALLED AFTER THE BASEBOARD INSTALLATION, THE CAR-

PETING CAN BE RUN UP TO THE FRONT AND AROUND THE HEATER BODY.

FULL LENGTH DRAPES: FOR THE MOST SATISFACTORY OPERATION OF

HEATERS, THE FOLLOWING CLEARANCES MUST BE MAINTAINED:

1. HANG DRAPES SO THAT, IN USE, THEY EXTEND BELOW THE CENTER

LINE OF THE HEATER, BUT WITH AT LEAST 1” (25mm) CLEARANCE FROM

THE TOP OF THE FINISHED FLOOR COVERING, SUCH AS CARPET, TILE,

ETC.

2. HANG DRAPES SO THERE IS AT LEAST 2” (51mm) BETWEEN THE

EXTREME FRONT OF THE HEATER AND THE NEAREST FOLD OF

DRAPES, IN THE FOLDED BACK POSITION (OPEN DRAPE POSITION).

3. HANG DRAPES SO THERE IS AT LEAST 1” (25mm) BETWEEN THE TOP OF

THE DRAPES AND THE CEILING.

SHORT DRAPES: HANG DRAPES SO THERE IS AT LEAST 6” (152mm) CLEAR-

ANCE ABOVE THE TOP OF THE HEATER.

FURNITURE: DO NOT PLACE FURNITURE AGAINST HEATER. IT IS RECOM-

MENDED ALL ITEMS BE KEPT A MINIMUM OF 6” (152mm) FROM HEATER.

INSTALLATION OF SINGLE UNIT

Liquid filled baseboard heaters are designed for installation in new or existing con-

struction. In existing construction, baseboard molding should be removed and the

heaters mounted flush against the wall surface. When replacing molding allow 1/16”

(1 mm) clearance between molding and ends of heaters.

NOTE: This heater can be wired in either the right or left hand junction box.

See Table 1 for wiring compartment volumes.

Table 1. Field Wiring Compartment Volumes

Est. Net Total Volume

Description

CM

3

In

3

Heater Wiring Compartment (One End)

200

13.25

Heater Wiring Compartment with

T1 or T2 Thermostat Accessory

175

11.25

Accessory Blank Section (No Controls)

2400

145

AC Accessory Section

2300

140

DR Accessory Section

2300

140

CDS2 Accessory Section

2300

140

LVR Accessory Section

2100

130

CAUTION

TO PREVENT POSSIBLE DAMAGE TO INTERNAL HEATER WIRING, ALL

DRILLING OF END CAPS MUST BE DONE WITH END CAPS REMOVED

FROM HEATER.

CAUTION

CAUTION

IMPORTANT

!

2

!

!

!

HEATER MAY BE INSTALLED ABOVE THE FLOOR SUCH AS ATOP A BASE-

BOARD. HOWEVER, THE POWER SUPPLY MUST ENTER THE HEATER

THROUGH THE KNOCKOUT IN THE BACK OF THE HEATER IF INSTALLED

ABOVE THE FLOOR.

2" (51mm) CLEARANCE

(MIN)

1" (25mm) CLEARANCE

(MIN)

BASEBOARD HEATER

EXAMPLE 1

W

ALL

FLOOR

CEILING

1" (25mm) CLEARANCE

(MIN)

DRAPERY

6" (152mm) CLEARANCE

(MIN)

BASEBOARD HEATER

EXAMPLE 2

W

ALL

FLOOR

CEILING

DRAPERY

1" (25mm) CLEARANCE

(MIN)

Figure 1. Positioning Drapery Near Heater

NOTE: ALLOW 1/8" (3mm) MINIMUM

CLEARANCE AT ENDS OF HEATER FOR

EXPANSION AND CONTRACTION

NAIL POINTS

FLOOR

Figure 2. Installation of Heater

1. Position the heater at the desired location on the wall as shown in Figure 2. For

maximum heating comfort, position the heater under a window.

2. Mark the location on the wall or floor for the power supply entry into the heater.

Remove the heater from the wall and drill appropriate hole in the wall or floor.

3. Remove the left or right junction box end cap by removing the screw in the end

of the heater and sliding the cap outward from the heater (Figure 3).

4. Remove the front cover of the heater by removing the screws in the lower cor-

ners. Pull the bottom of the cover outward and lift the top of the cover off the

junction box. Repeat for the opposite end. Snap the top of the cover off the cen-

ter bracket and off the intermediate supports. See Figure 4.

5. Remove the appropriate electrical knockout from the back of the heater or

accessory if necessary. Supply wiring may also enter the raceway through the

floor or wall without using a knockout.