MPI Technologies FCX User Manual

Page 19

67$5783 $1' 23(5$7,21

$'-867,1* 7+( 2,/ %851(5

While the oil burner is adjusted at the factory, it is re-

commended that the operating characteristics of the

burner be determined at start-up and readjusted if

necessary. Run the unit long enough at the burner

maximum firing rate to make sure the burner has

reached a stable maximum operating temperature.

THEN, check the burner and adjust as follows:

Check to determine that the smoke spot number

does not exceed 0.5 with a Bacharach control. Ad-

just the burner as required to achieve this maximum.

Check to determine that the CO2 rate is from 12 - 13

percent and that there is no CO production. Adjust

the burner as required to achieve this operating cha-

racteristic.

Measure the temperature of the flue gas exiting the

unit to determine that it does not exceed 250 de-

grees F (120 C).

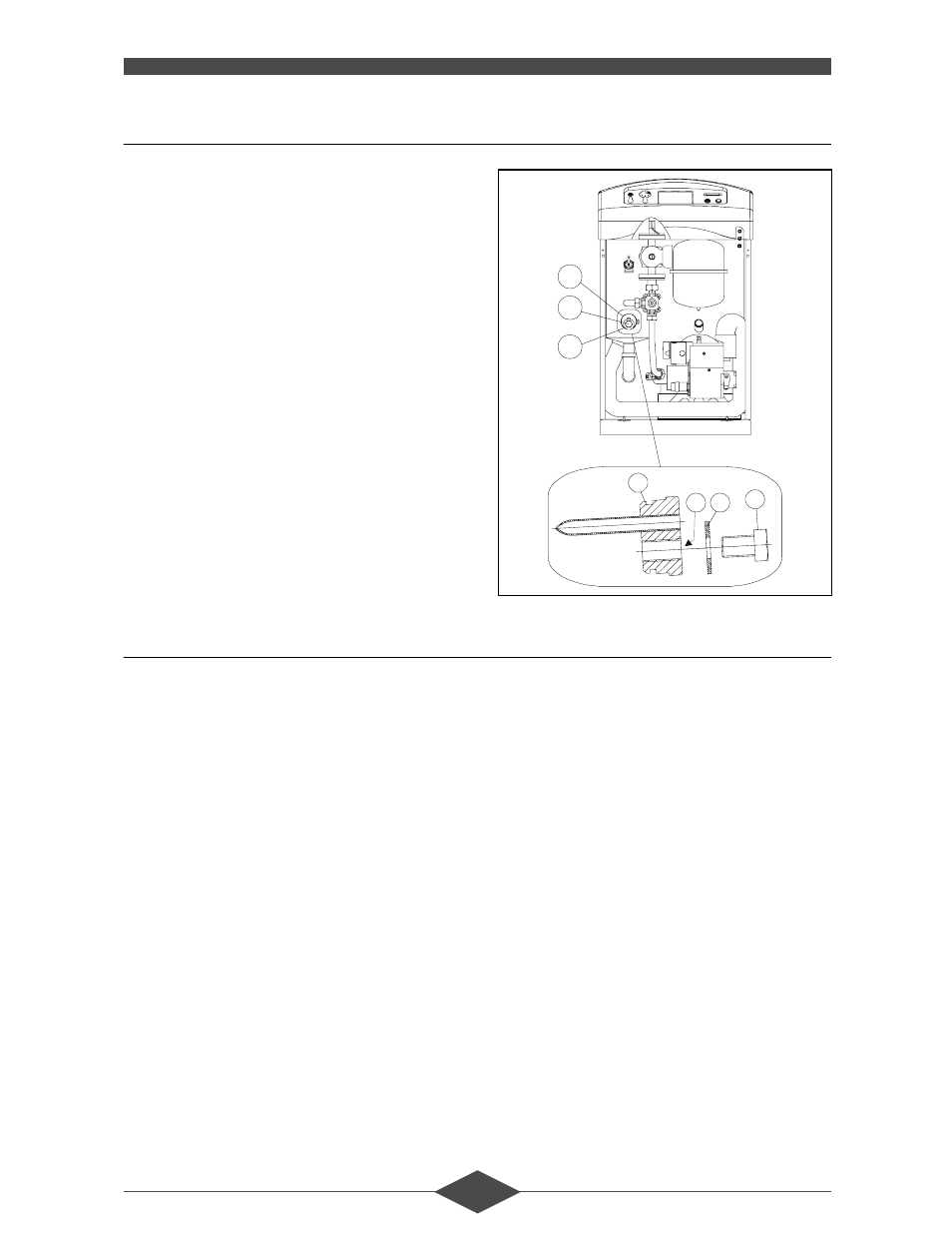

Combustion inspection can be carried out on the

unit through the hole (item N) provided in the inspec-

tion port (item 7). Be sure to replace the washer

(item M) and the test point screw (item 6) properly

after inspection.

&+(&.,1* 7+( 6$)(7< '(9,&(6

At the time of start-up, check the safety and control

devices as follows :

- Thermostats :

• Check to see that the thermostat bulbs are

correctly positioned in their housings. This is

essential to provide temperature sensing to

facilitate burner shut-down in the event of

overheating,

- Flame monitoring :

• Check to make sure that the burner shuts

down properly upon the deactivation or discon-

nection of the flame monitoring device or inter-

ruption of the flow of fuel,

- Safety Pressure Relief valve :

• Check the safety pressure relief valve in the

heating circuit for proper operation.

6

7

7

6

M

N

M