3. run-in procedure using resistance grid – Miller Electric 600 X User Manual

Page 80

OM-4428 Page 76

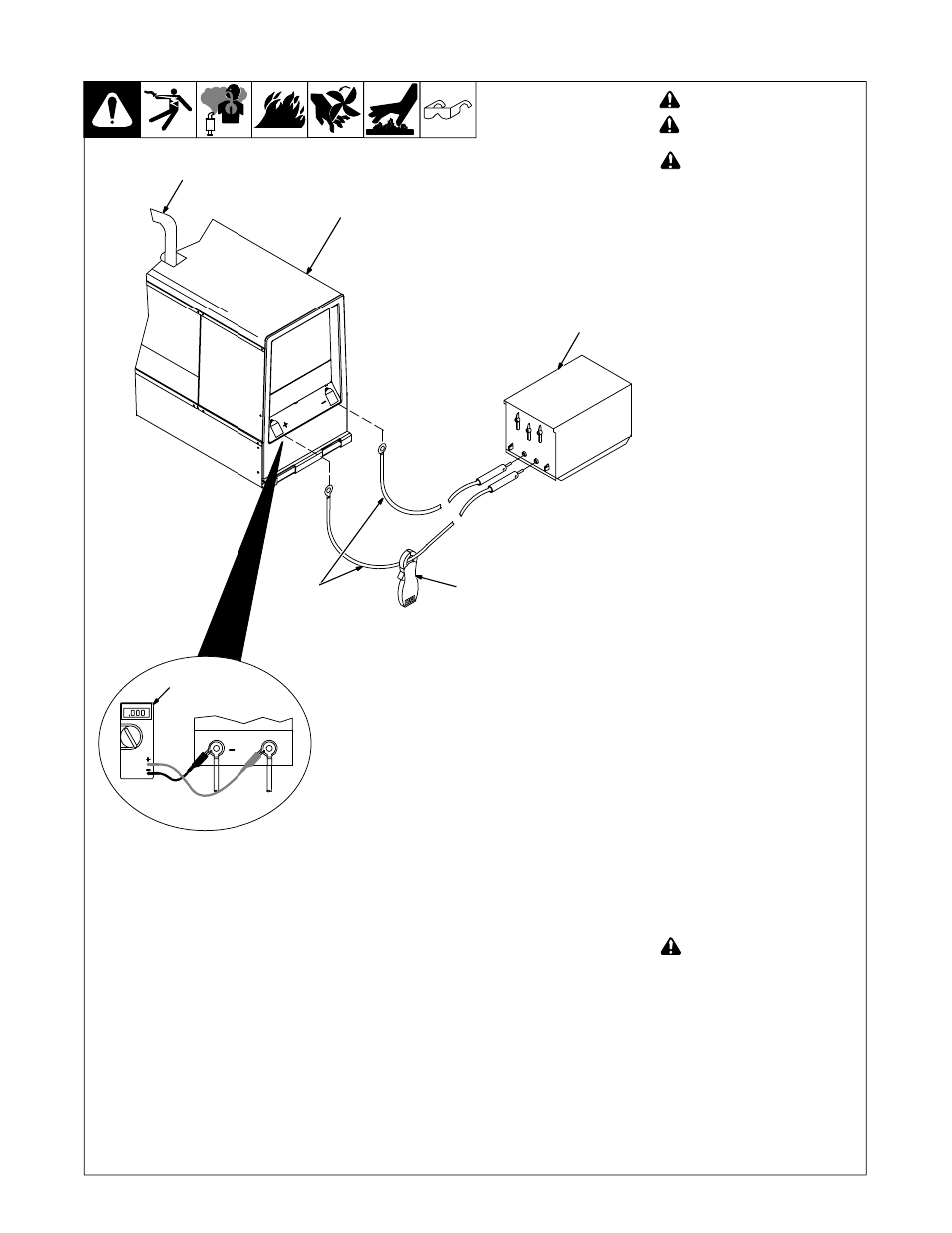

13-3. Run-In Procedure Using Resistance Grid

S-0684

1

Resistance Grid

Use grid sized for generator rated

output.

Turn Off grid.

2

Welding Generator

Place A/V range switch in maxi-

mum position, A/V control in mini-

mum position, and Output Selector

switch (if present) in either DC

position.

3

Weld Cables

Connect grid to generator weld

output terminals using proper size

weld cables with correct connec-

tors (polarity is not important).

4

Voltmeter

5

Clamp-On Ammeter

Connect voltmeter and ammeter as

shown, if not provided on generator.

Start engine and run for several

minutes.

Set grid switches and then ad-

just generator A/V control so

load equals rated voltage and

current of the generator (see

nameplate, rating label, or the

specifications section in this

manual).

Check generator and meters after

first five minutes then every fifteen

minutes to be sure generator is

loaded properly.

NOTICE − Check oil level frequent-

ly during run-in; add oil if needed.

It is recommended to run the weld-

ing generator for two hours mini-

mum and up to four hours under

load. Place A/V control in minimum

position, then shut down grid to

remove load. Run engine several

minutes at no load.

1

3

5

+

4

2

6

Stop engine.

Do not touch hot exhaust pipe,

engine parts, or load bank/grid.

Keep exhaust and pipe away

from flammables.

NOTICE − Do not perform run-

in procedure at less than 20

volts weld output and do not

exceed duty cycle or equip-

ment damage may occur.

Stop engine and let cool.

6

Engine Exhaust Pipe

Repeat procedure if wetstacking is

present.