Manitowoc Ice Q-0280 User Manual

30” q-model water/remote insulation

30” Q-Model Water/Remote Insulation

Installation Instructions

Material List Q-0280 - Q-1000 Water and Remote Ice Machines:

Quantity

1

Armaflex Insulation

6’ x 2” ID x 3/8” wall thickness

1

Armaflex Insulation

6’ x 3/4” ID x 3/8” wall

(used on evaporator inlet/outlet and dump valve drain line)

1

Bulkhead Insulation Back

9” x 30” x 3/4”

1

Bulkhead Insulation Back

3” x 30” x 3/8”

2

Side Wall Insulation

9” x 10” x 3/4”

1

Vacuum Formed Base with Insulation

12 3/4” x 30” x 3/4"

1

Foam Gasket For Top Edge of Bin

2’ x 3/4” x 1/4”

1

Tube Silicone Sealant Black

Used to seal base/bulkhead insulation

1

Tube Silicone Sealant White

Used to seal front edge of vacuum-formed base

1

Mylar

Strip

5”

x

25”

Additional materials required: caulk gun, 2” x 4” wood blocks, wire ties.

Preparation

1. Disconnect power from ice machine.

2. Remove front, top, and side panels.

3. Drain water from sump trough.

4. Ice machine must be thoroughly dried before the insulation can be installed. Use towels to dry bulkhead and base assembly.

Base Insulation Installation

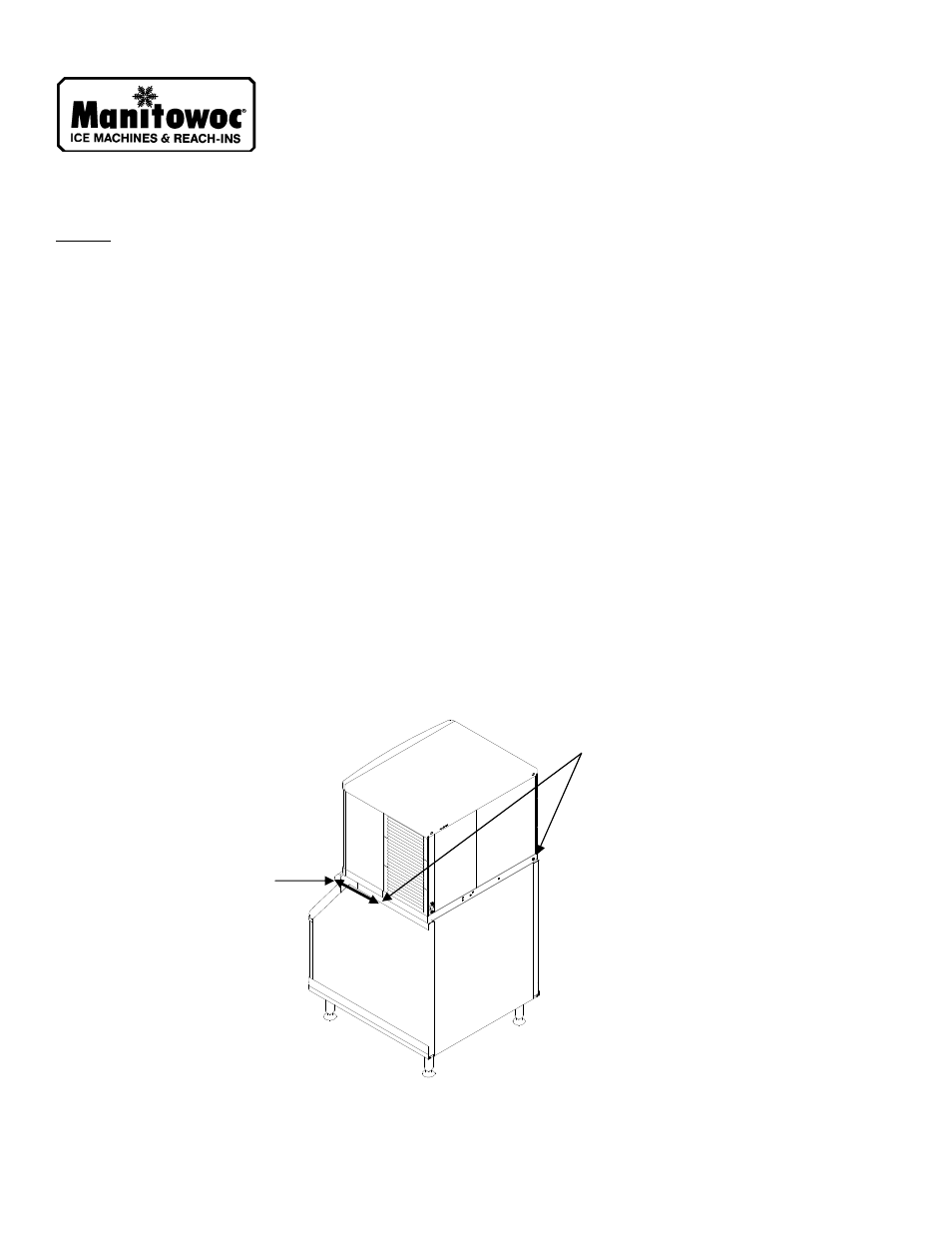

1. Raise the ice machine above the bin. A high lift can be used or (two people required) lift front edge of ice machine and place

wood blocks (2” x 4”) between ice machine and bin. Lifting one side of ice machine at a time, move wood blocks to center

balance point of ice machine.

2. Slide vacuum-formed base insulation assembly between the ice machine and bin. Align the insulation with the back and sides of

the bin and ice machine.

3. Add one layer of foam tape insulation from the front of the bin to the front of the base insulation on the left and right side.

Manitowoc Ice, Inc.

2110 South 26 Street, P.O. Box 1720, Manitowoc, WI 54221-1720 USA 8005493

Telephone 920-682-0161, Fax - Sales: 920-683-7589, Service/Parts: 920-683-7585, Other: 920-683-7879

Sheet 1 of 3

Web Site -

www.manitowocice.com

06/02/00

4. Raise front of ice machine and position the wood blocks on edge (3 1/2” height). This will allow the top of the vacuum-formed

base to be accessed.

3. Add foam tape both sides.

2. Install vacuum-formed base

insulation and align back and sides.