Hea ter inspection and maintenance schedule – Munchkin Gas-Fired Hot Water Circulating Heater User Manual

Page 68

67

GAS-FIRED HEATER

Installation Manual

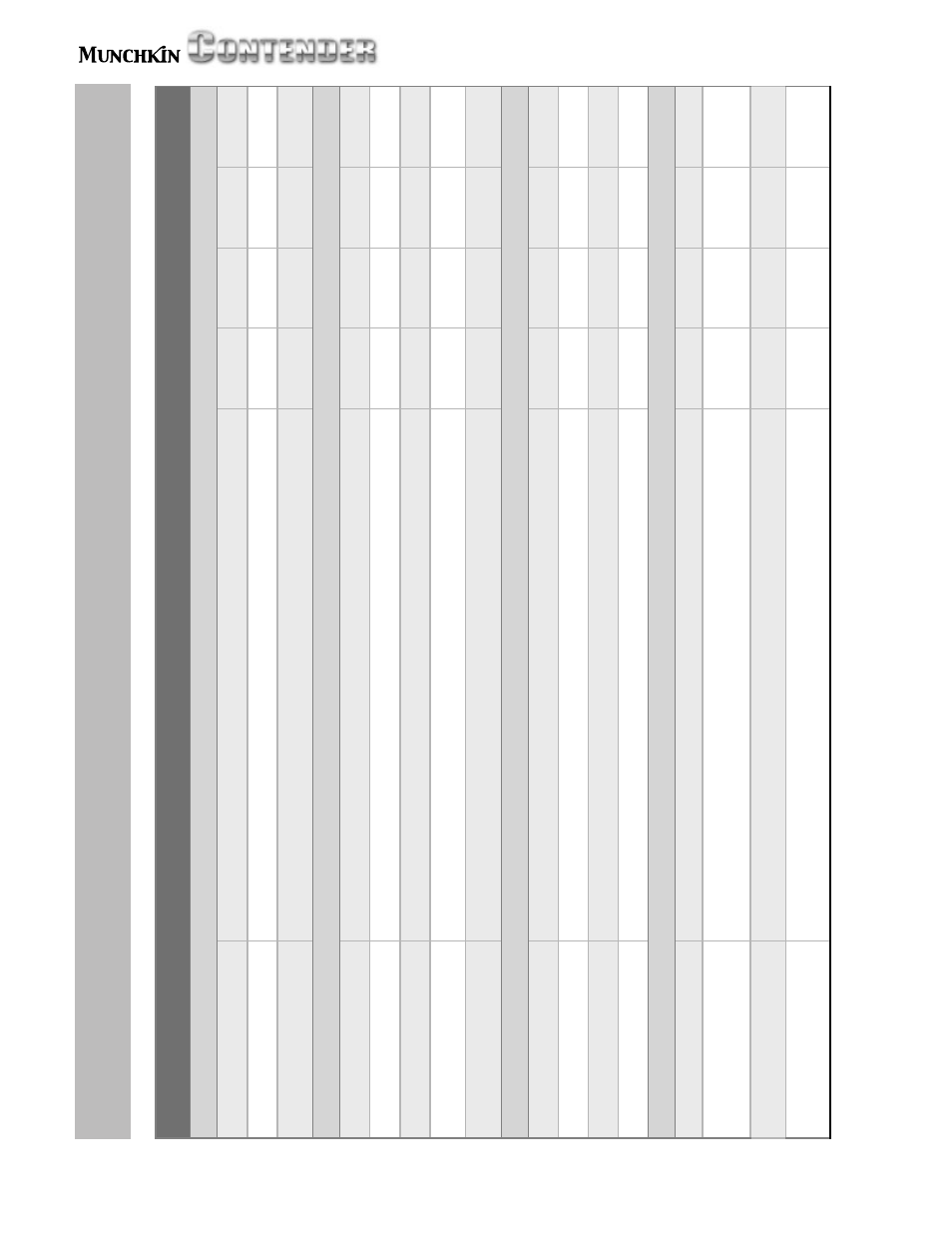

Inspection Activities

Piping

1st Year

2nd Year

3rd Year

4th Year*

Near Heater Piping

Check heater and system piping for any sign of leakage, verify proper support

Vent

Check condition of all vent pipe and joints

Gas

Check gas piping, test for gas leaks and signs of aging, make sure all pipes are supported properly.

System

Visual

Do a full visual inspection of all system components

Functional

Test all functions of the system (Heat, DHW, Safeties)

Temperatures

Verify safe settings on Super-Stor indirect fired water heater or Anti-Scald Valve ( see part 12 for

realted safet

y warnin

gs

)

Temperatures

Verify temperature settings programmed into the heating curve ( See Part 13)

Electrical

Connections

Check wire connections, make sure they are tight

Circuit breakers

Check to see that the circuit breaker is clearly labeled, exercise circuit breaker

Switch and Plug

Verify ON/OFF switch and convenience plug are both functional

Smoke and CO detector

Verify devices are installed and working properly, change batteries if necessary

Chamber and Burner

Combustion Chamber

Vacuum Combustion Chamber if Necessary

Combustion Chamber

Check burner tube, and combustion chamber coils, clean according to maintenance section of

manual

Spark Electrode

Clean with scoth brite , Set gap at 1/4" (see Fig 14-2 Part 14 in Troubleshooting section)

Flame Probe

Clean with scoth brite , Check ionization in

µA (d7 on status menu in Start-up Procedures) record

high fire (3.8 to 4.2) and low fire (3.0 to 3.4)

* NOTE : CONTINUE MAINTENANCE BEYOND THE 4TH YEAR IS REQUIRED ON A YEARLY BASIS.

Date last completed

HEA

TER INSPECTION AND MAINTENANCE SCHEDULE