Setting up your log splitter warning – MTD 510 User Manual

Page 7

7

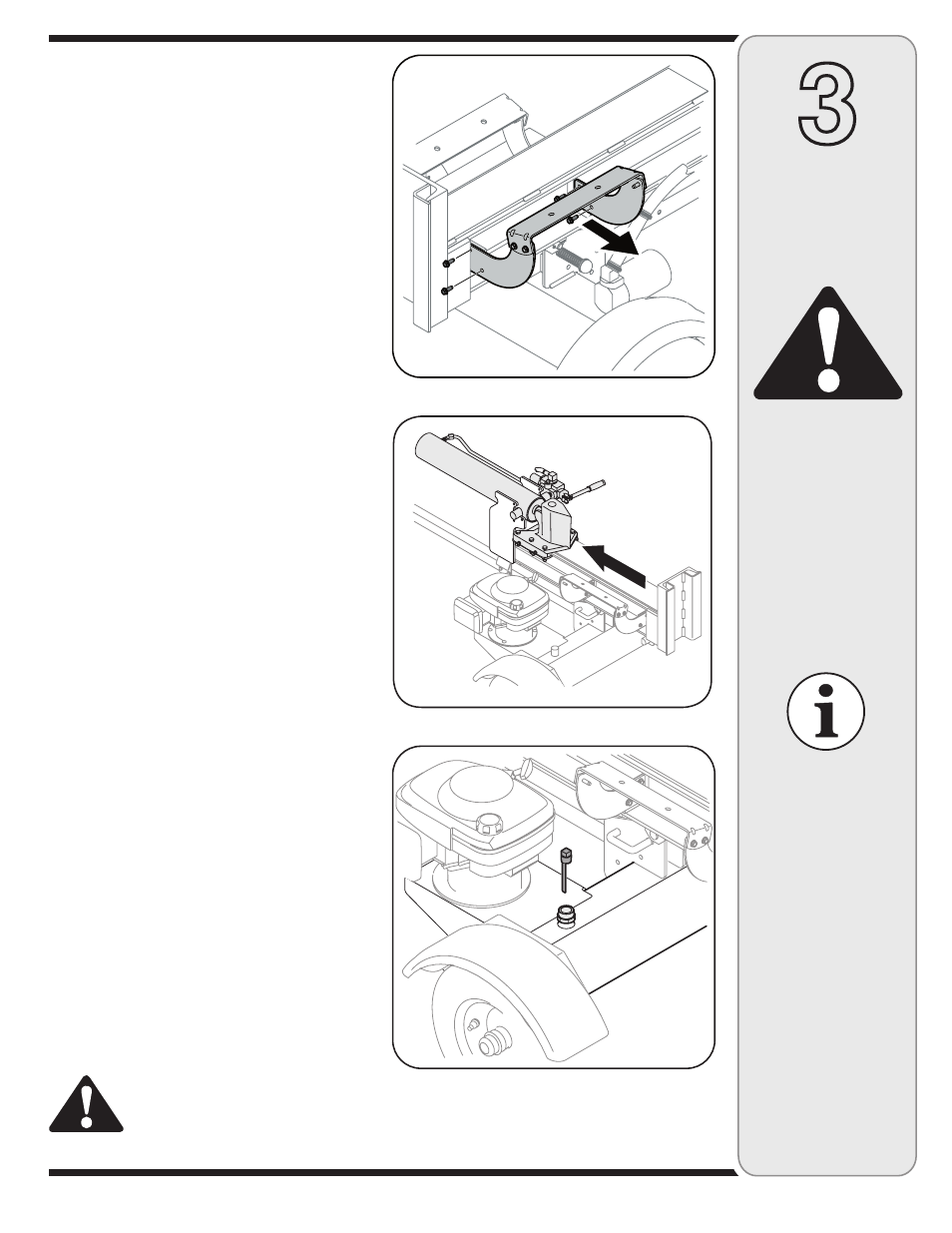

3. Disconnect the log cradle from the beam on the side

of the control valve. See Figure 3-5.

4. Lift and slide the cylinder up to the top of beam and

into the weld brackets. See Figure 3-6.

5. Attach the dislodger over the wedge assembly and

secure with hardware, previously removed, to the weld

brackets.

NOTE: Once the six hex screws are tightened, there

may be a slight gap between the dislodger and the weld

brackets. This gap is normal.

6. Reattach the log cradle to the side of the beam with

the control valve, aligning the ends of the cradle with

the beam flanges.

7. Roll log splitter off the bottom crate.

Preparing the Log Splitter

1. Lubricate the beam area (where the splitting wedge

will slide) with engine oil; do not use grease.

2. Remove vented reservoir dipstick, which is located in

front of the engine on top of the reservoir tank. See

Figure 3-7.

IMPORTANT: The log splitter may have been shipped

and primed with hydraulic fluid in the reservoir tank. If not,

proceed with the following steps:

3. Fill the reservoir tank with hydraulic fluid included with

this unit (if equipped) or approved fluids which include

Dexron® III / Mercon® III automatic transmission fluid,

a 10 Weight AW hydraulic oil or Pro-Mix™ AW-32

Hydraulic Oil.

4. Check fluid level using the dipstick. See Figure 3-7. Do

not overfill.

5. Replace vented dipstick securely, tightening it until the

top of the threads are flush with top of the pipe.

6. Disconnect the spark plug and prime the pump by

pulling the recoil starter as far as it will go. Repeat

approximately 10 times.

7. Reconnect the spark plug wire and start engine

following instructions in the OPERATION section.

8. Use control handle to engage the wedge to the

farthest extended position. Then retract the wedge.

9. Refill tank as specified on the dipstick.

NOTE: Failure to refill the tank will void unit’s warranty.

10. Extend and retract the wedge 12 complete cycles

to remove trapped air in the system (the system is

“self-bleeding”).

11. Refill reservoir within range marked on the dipstick.

WARNING: Much of the original

fluid has been drawn into the cylinder

and hoses. Make certain to refill the

reservoir to prevent damage to the

hydraulic pump.

3

Setting Up

Your Log

Splitter

WARNING

Much of the original

fluid has been drawn

into the cylinder and

hoses. Make certain to

refill the reservoir to

prevent damage to the

hydraulic pump.

NOTE: Some fluid may

overflow from the vent

plug as the system

builds heat and the

fluid expands and

seeks a balanced level.

Figure 3-7

Figure 3-6

Figure 3-5

NOTE: Some fluid may overflow from the vent plug as

the system builds heat and the fluid expands and seeks

a balanced level.

IMPORTANT:

The log splitter may

have been shipped and

primed with hydraulic

fluid in the reservoir

tank. If not, proceed

with the following

steps: