Welding technology – Metabo Welding Technology User Manual

Page 4

| 325

U; I

U; I

t

t

E 130

3,25 mm

1,5–5 mm**

•

• –

• • •

E 150

3,25 mm*

1,5–5 mm**

•

• –

• • •

E 170 Si

4,0 mm

1,5–5 mm**

•

• –

• • •

SK 200

5,0 mm

2,5–6 mm

•

• –

–

–

–

SK 230

5,0 mm

2,5–7 mm

•

• –

–

–

–

SB 140

3,25 mm

2,5–4 mm

•

• –

–

–

–

SB 200 CT

4,0 mm

2,5–5 mm

•

• –

–

–

–

TIG welding

Device type

Weldable

Weldable materials

Material

thickness

Steel

Stainless steel (VA)

Nonferrous heavy metals

Aluminium

TIG 170 DC

0,3–6 mm

•

• •

–

TIG 170 AC/DC

0,3–6 mm

•

• •

•

MIG/MAG welding

Device type

Weldable

Weldable

Weldable materials

wire

Material

thickness

Steel

Stainless steel (VA)

Aluminium

MIG/MAG 140

0,6–0,8 mm

0,5–3 mm

•

•

*

MIG/MAG 160

0,6–0,8 mm

0,5–4 mm

•

•

*

MIG/MAG 150/20 XT

0,6–0,8 mm

0,5–5 mm

•

• •

MIG/MAG 170/30 XTC

0,6–0,8 mm

0,5–6 mm

•

• •

MIG/MAG 200/40 XT

0,6–1,0 mm

0,5–8 mm

•

• •

MIG/MAG 250/60 XT

0,6–1,2 mm

0,5–10 mm

•

• •

MIG/MAG 300/45 XT

0,6–1,2 mm

0,5–15 mm

•

• •

Note: The specified material thickness values are only standard values.

Thicker materials can naturally also be processed by appropriate

seam preparation and multi-layer structure of the weld seam.

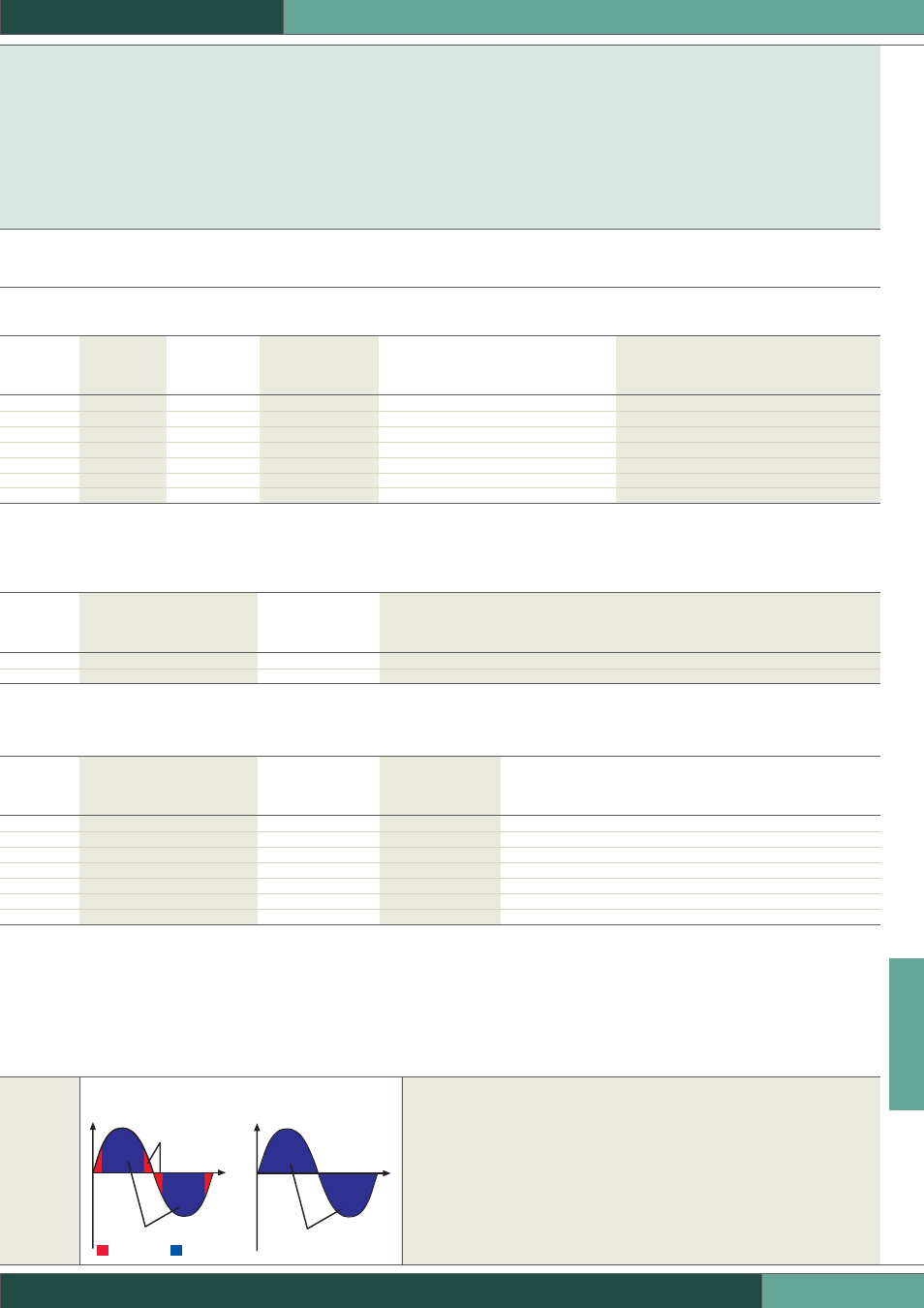

SINUS INVERTER TECHNOLOGY.

No oversized current generators

due to the reduced power con-

sumption.

Welding gaps that can be caused

by long cable extensions, are a

thing of the past.

Future standards are already

met today.

An optimisation of the output factor

is achieved using the sinus-inverter

techno logy by Metabo. This means

that a higher output is possible with

lower current consumption from the

230 V energy supply.

Advantages:

High welding output at 230 V

(electrode up to 170 A).

* Cr Ni up to 4.0 mm ** TIG from 0.3 mm on

*** except aluminium

Standard inverter

Sinus inverter

Loss

Output

* conditionally applicable

SA

W

S

SPE

CIAL

-PURPOSE

MA

CHINES

S

Y

S

TEMA

TIC

OR

GANIS

A

T

ION

GARDEN

W

OOD-PR

OCESSING

TE

CHNOL

OG

Y

W

A

TER-/PUMP

TE

CHNOL

OG

Y

WELDING

TE

CHNOL

OG

Y

COMPRESSED

AIR S

Y

S

T

EMS

WELDING TECHNOLOGY

ficiently. Example: The innovative sinus inverter techno-

logy by Metabo. High welding output but low fuel con-

sumption. Or the microprocessor control – we call it

“Smart Intelligence” – with state-of-the-art electronics

for ideal welding results.

Electrode welding

Device type

Max. Ø

Weldable

Weldable materials with electrode

Weldable materials with TIG

Electrodes

Material

Steel

Stainless

Aluminium

Steel

Stainless

Nonferrous

thickness

steel (VA)

steel (VA)

heavy metals***

Which welding device is suitable for which material?