Metabo TIG 170 AC/DC User Manual

Tig welding systems

334 |

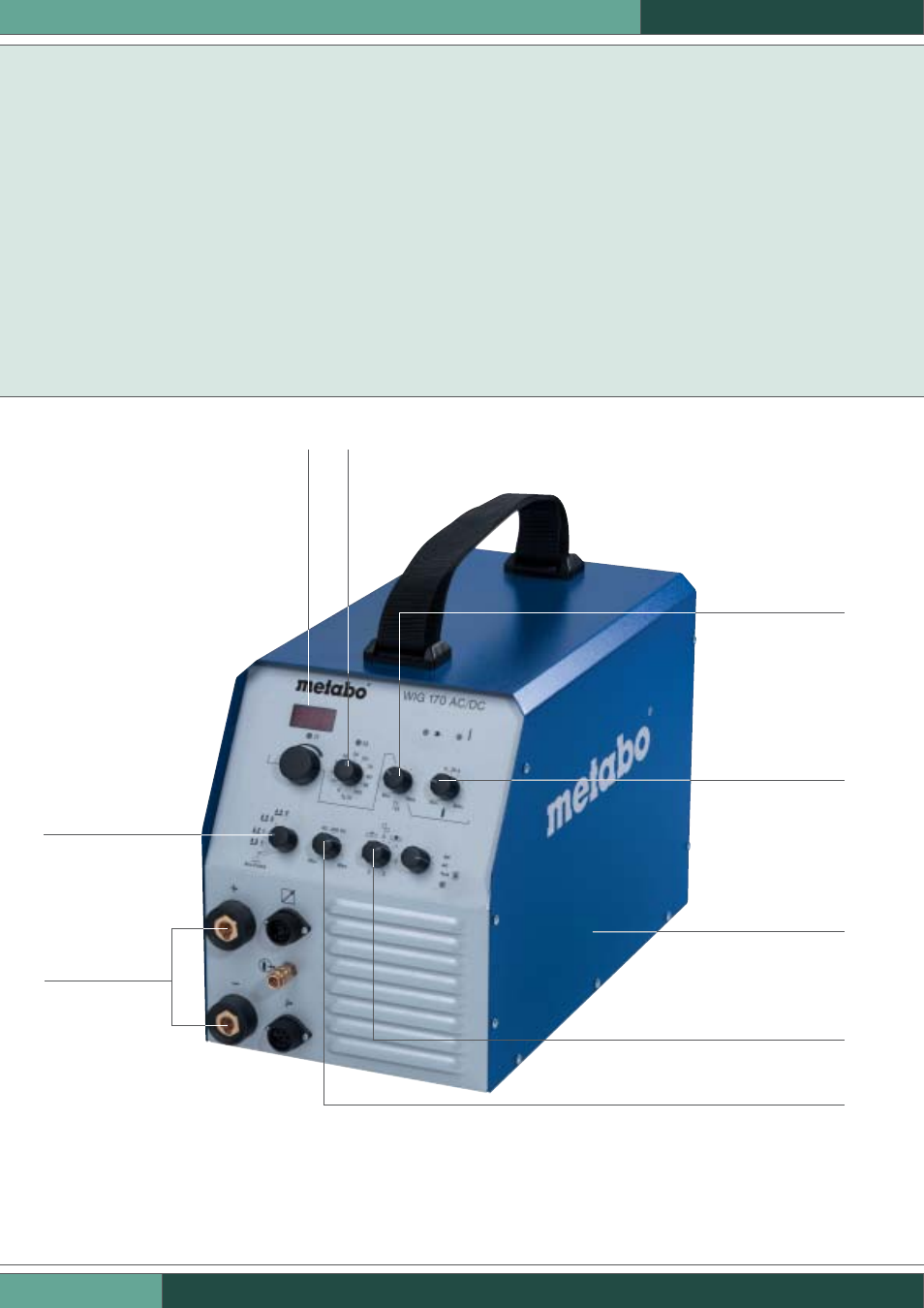

e.g. TIG 170 AC/DC

Smart intelligence

State-of-the-art processor

control for simple operation

and ideal welding results.

“S mark“

Approved for welding even in narrow spaces with

increased electrical risk. Automatic test function

with switch for testing the “S-wave”.

“HF ignition”

for contact-free ignition

of the TIG electric arc.

2/4-cycle control for

comfortable working.

Digital welding current indicator

with automatic nominal and

actual value changeover.

Electrode function

with switch and automa-

tic hot start, arc

force control and anti-

stick regulation for

perfect, even welding

results without

sticking.

Torch and earth cable

can be removed.

Infinitely adjustable second current

for protecting the material from

overheating.

Automatic finishing

device

Infinitely adjustable

welding current reduction

for a clean welded end.

Continuously

adjustable gas

post flow time

for perfect gas

management.

Sturdy metal housing

with protection class

IP 23C for safe use

in rough construction

site conditions.

Frequency control

during TIG AC welding can be

adjusted for a stable electric arc.

Balance control

during TIG AC welding can be adjusted

for ideal fusion penetration.

TIG WELDING SYSTEMS

SOME LIKE IT HOT.

The centrepiece of a TIG welding device is the optimum

ignition and control. That makes welding devices real

perfectionists: they can handle all metals from 0.3 mm

on with direct or alternating current, depending on the

material. Your advantage: They are so good at handling

the concentrated splash-free electric arc, that bother-

some reworking is now a thing of the past. Metabo wel-

ding systems are produced as highly dependable tools:

Only after successfully passing all air condition, dust

chamber and vibration tests and then being checked

again thoroughly, do they leave our factory.