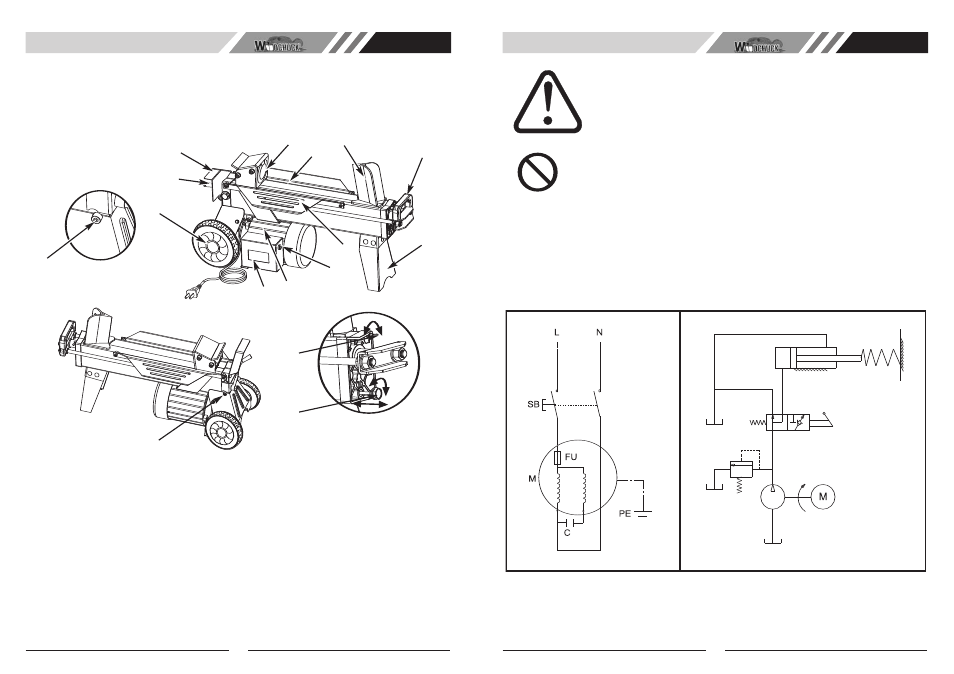

Set up and preparation for operation, Wiring diagram plumbing diagram – McCulloch Woodchuck FB4052 User Manual

Page 4

7

6

EN

1. Log Pusher

2. Work Table

3. Wedge

4. Lift Handle

5. Support Leg

6. Log Retaining Plates

7. Switch

8. Motor

9. Pushbutton Box

10. Wheels for Minor Moving ONLY.

11. Hydraulic Control Lever

12. Control Lever Guard

13. Bleed Screw

14. Oil Drain Bolt w/ Dipstick

15. Max Pressure Limiting Screw

12

6

2

1

3

3

10

4

SET UP AND PREPARATION FOR OPERATION

1.

Bolt the Support Leg to the Log Splitter, lift the log splitter by the handles at both ends and place it on

a 60 - 75cm high, stable, flat and level work surface.

2.

Familiarize yourself with the controls and features of this log splitter in the illustrations.

11

5

7

8

9

1

14

Before operating the log splitter, the Bleed Screw should be loosened by some rotations until air

can go in and out of the oil tank smoothly.

Air flow thru the Bleed Screw hole should be detectable during the log splitter is under operations.

Before moving the log splitter, make sure the Bleed Screw is tightened to avoid oil leaking from this

point.

FAILED TO LOOSEN THE BLEED SCREW WILL KEEP THE SEALED AIR IN

HYDRAULIC SYSTEM BEING COMPRESSED AFTER BEING DECOM-

PRESSED. SUCH CONTINUOUS AIR COMPRESSION AND DECOMPRES-

SION WILL BLOW OUT THE SEALS OF THE HYDRAULIC SYSTEM AND

CAUSE PERMANT DAMAGE TO THE LOG SPLITTER.

15

EN

DO NOT ADJUST THE MAX PRESSURE LIMITING SCREW !.

Max pressure was set before the log splitter ex work and the max pressure limiting screw is sealed

with glue to ensure the log splitter works under pressure no more than 4 tons. The setting was done

by qualified mechanic with professional instruments.

Unauthorized resetting will cause the hydraulic pump fail to output enough splitting pressure or

RESULT IN SERIOUS INJURY AS WELL AS DAMAGE TO THE MACHINE .

WIRING DIAGRAM PLUMBING DIAGRAM

15