6. adjusting tension at feeder – Miller Electric OM-227 398D User Manual

Page 14

OM-227 398 Page 10

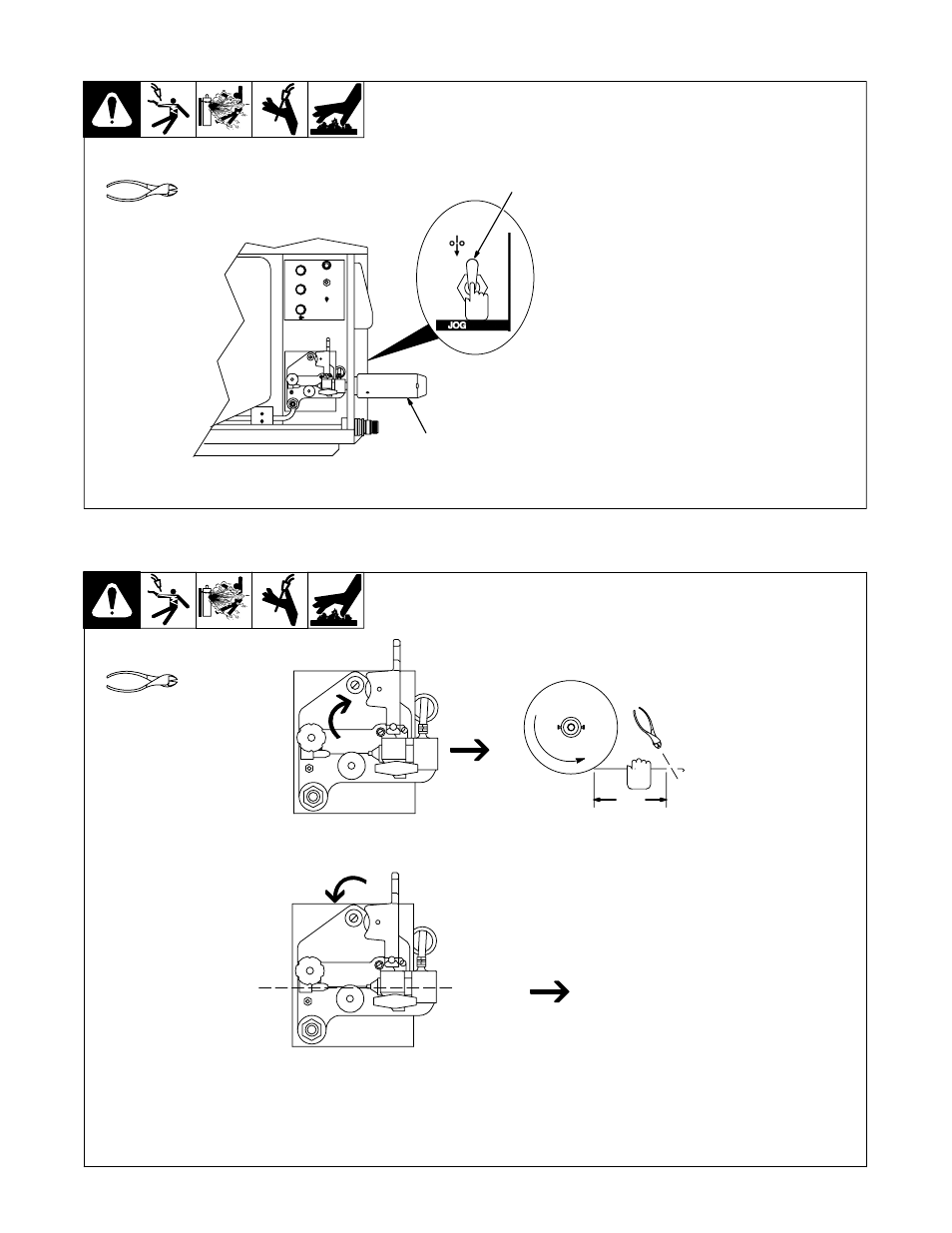

4-5. Threading Welding Wire Through XR-Control Feeder

Ref. 802 193-A

Tools Needed:

2

1

1

Cable Assembly

Lay cable assembly out straight.

2

Jog Switch

Push Jog switch up to feed wire through

cable assembly.

.

Hold wire tightly to keep

it from unraveling.

4-6. Adjusting Tension At Feeder

Ref. 802 193-A

Tools Needed:

Pull and hold wire; cut off end.

6 in

(150 mm)

Open tension arm.

Thread wire thru inlet guide, along drive roll groove, and

into wire conduit. Close tension arm. Adjust tension as

follows: grasp spool with one hand, press Jog switch, and

turn thumb nut clockwise until motor stalls when Jog

switch is pressed. Back thumb nut off slightly.

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)