English – Middleby Marshall PS570S User Manual

Page 12

12

ENGLISH

A. Gas Utility Rough-In Recommendations

The following gas system specifications are STRONGLY

RECOMMENDED. Deviating from these recommendations

may affect the baking performance of the oven.

Gas Meter

One or two oven cavities: 750 cfh meter

Three or four oven cavities: 1200 cfh meter

Gas Line

DEDICATED LINE from the gas meter to the oven

2-1/2" (63.5mm) pipe for natural gas

2" (50.8mm) pipe for propane

Maximum length: 200' (61m). Each 90° elbow equals 7'

(2.13m) of pipe.

B. Connection

Check the ovens gas supply requirements before making the

gas utility connection. Gas supply requirements are listed on

the ovens serial plate.

Check the serial plate to determine the type of gas (Propane or

Natural) to be used with the oven.

Refer to the instructions in the gas hose package (included in

the Installation Kit) before connecting the gas line. One gas line

connection method is shown in Figure 2-14; however,

compliance with the applicable standards and regulations is

mandatory.

Inlet, regulated, and pilot gas pressure readings can be taken

using a U tube manometer at the tap locations shown in

Figure 2-15.

NOTE

In the USA, the installation must conform with local codes, or in

the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1.

In Canada, the installation must conform with local codes, or in

the absence of local codes, with the Natural Gas Installation

Code, CAN/CGA-B 149.1, or the Propane Installation Code,

CAN/CGA-B 149.2, as applicable.

In Australia, the installation must conform with AGA Code

AG601 and with any requirements of the appropriate statutory

authority.

Certain safety code requirements exist for the installation of gas

ovens; refer to the beginning of this Section for a list of the

installation standards. In addition, because the oven is equipped

with casters, the gas line connection shall be made with a

connector that complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 (in U.S.A.), or, if appli-

cable, Connectors for Movable Gas Appliances, CAN/CGA-6.16

(in Canada), as well as a quick-disconnect device that complies

with the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI Z21.41 (in U.S.A.), or, if applicable, Quick-

Disconnect Devices for Use With Gas Fuel, CAN1-6.9 (in

Canada).

C. Gas Conversion

Where permitted by local and national codes, it is possible to

convert ovens from natural to propane gas, or from propane to

natural gas. Use the appropriate Middleby Marshall Gas

Conversion Kit for the specific oven model.

CAUTION

The terms of the oven's warranty require all start-ups,

conversions and service work to be performed by a Middleby

Marshall Authorized Service Agent.

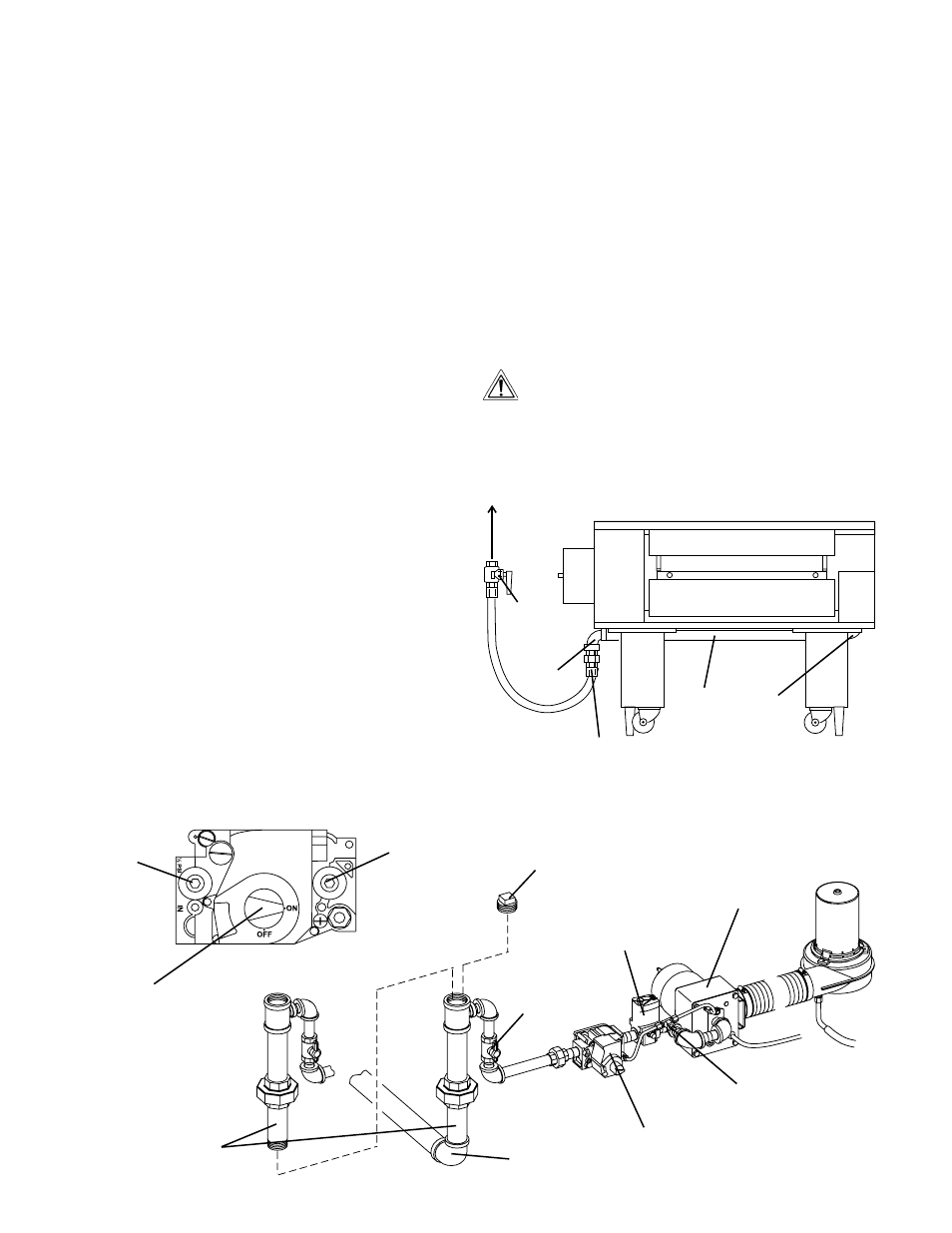

Figure 2-14 - Flexible Gas Hose Installation

To Gas

Supply Pipe

90°

Elbow

Union OR quick-

disconnect device

Flexible

Gas Hose

Full-Flow

Gas

Shutoff

Valve

90°

Elbow

Figure 2-15 - Gas Burner and Piping Assembly

Pilot pressure tap

(where pilot gas

pressure is

measured)

Combination Gas

Control Valve

(Safety Regulator)

Gas Burner

Burner

Blower

Inlet pressure

tap (where

incoming gas

pressure is

measured)

Manifold

pressure tap

(where manifold

gas pressure is

measured)

On/Off Knob

Always leave in

ON position

Manual

shutoff

valve

Gas line for

other oven

cavities

Cap for top

oven cavity

Nipple, 1-1/4

dia. X 3

(76mm) L, NPT

Elbow, 90°,

1-1/4 dia.

Modulating

gas valve

SECTION 2 - INSTALLATION

54"

(1372mm)

gas pipe