Information on the rating plate, 1 placing the machine, Hot-start function – Metabo E 130 User Manual

Page 8: Arc-force function, Anti-stick function, 1 manual arc welding, Connect the earth cable to the - pole, Connect the welding cable to the + pole, Turn master switch on, 2 tig welding

8

ENGLISH

Information on the rating plate:

4.1

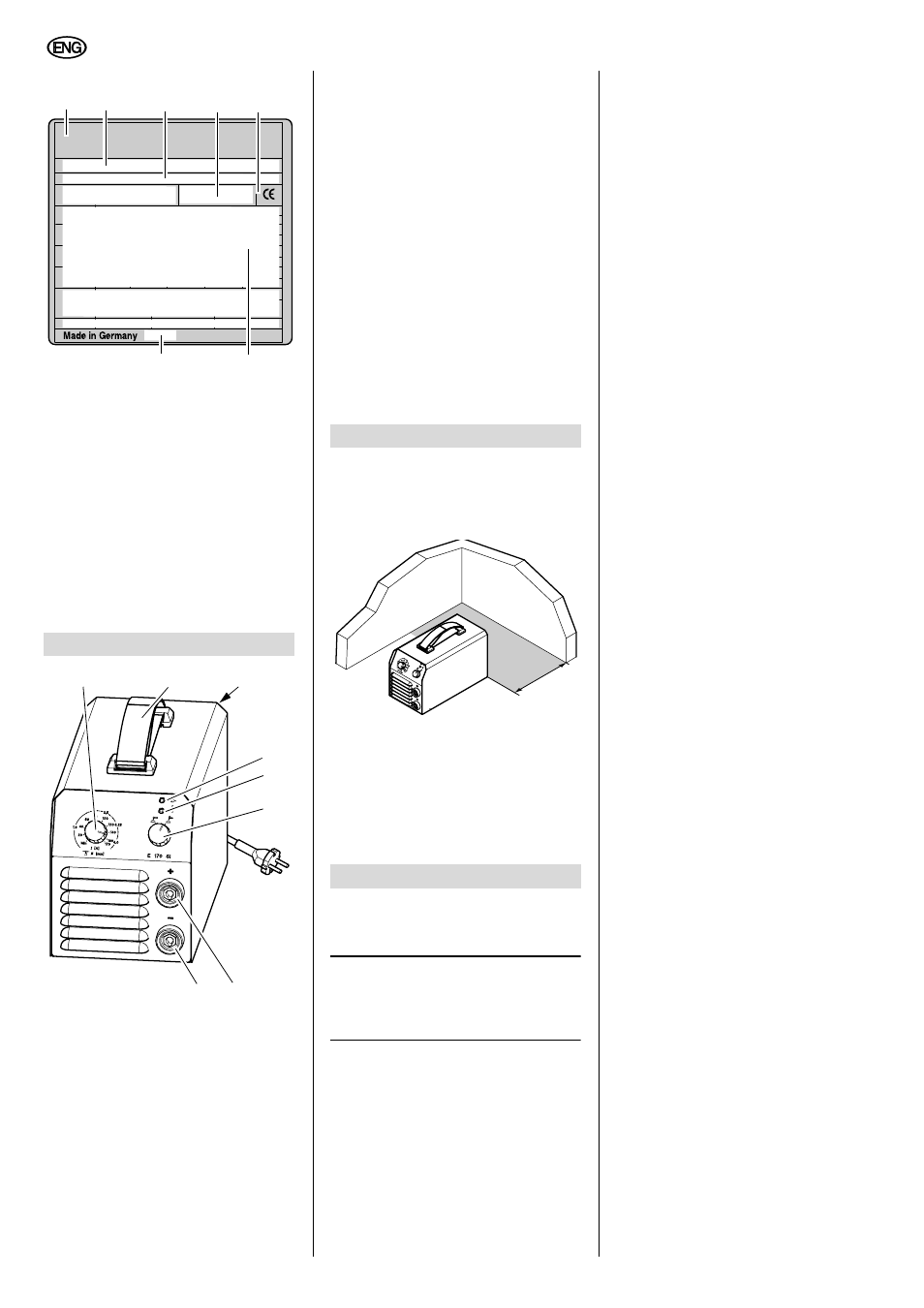

Placing the machine

A

Caution!

Always stand the machine on

its feet only.

The machine draws in air at its front

and bottom, which is given off

through the ventilating slots at the

rear. Ensure an unhindered airflow.

The distance of the machine to walls

or other equipment must be at least

20 cm.

A

Caution!

Check all connections and

supply lines before turning on.

3

Note:

For manual arc welding this

machine uses the Hot-start, Arc-force

and Anti-stick functions.

Hot-start function

When contacting the weld metal with the

electrode, the set welding current is

increased for a short period to ensure

that the arc will start.

This brief increase of the welding current

is limited to the maximum electrode cur-

rent.

Arc-force function

During the welding process the machine

keeps the energy (heat) brought into the

weld metal at a constant level, even if

the distance between electrode and

weld pool varies.

Anti-stick function

If the machine detects a short-circuit in

the welding process, it will switch to min-

imum current within 0.5 sec to keep the

electrode from burning out.

5.1

Manual arc welding

1.

Connect the earth cable to the –

pole.

2.

Connect the welding cable to the +

pole.

A

Caution!

Note information on polarity

shown on the packaging of the elec-

trodes used; reverse polarity, if nec-

essary.

A

Caution!

For manual arc welding the

Lift-arc ignition must be disabled. To

check, turn the rotary switch counter-

clockwise.

3.

Attach earth cable at a suitable loca-

tion of the workpiece.

4.

Turn master switch ON.

5.

Set desired welding current.

The welding machine is now opera-

tional.

5.2

TIG welding

When using a TIG welding torch

(optional accessory), both models can

also be used for TIG welding.

1.

Connect the welding current cable

of the TIG torch

(– pole).

2.

Check the gas supply to the TIG

torch.

3.

Attach the earth cable at a suitable

location of the workpiece (+ pole).

4.

Turn master switch ON.

5.

Set desired welding current.

6.

Activate Lift-arc ignition.

To check, turn the rotary switch

clockwise.

The welding machine is now opera-

tional.

TIG welding

The arc can only be started by touching

the workpiece with the electrode (Lift-arc

ignition).

Manufacturer

Machine designation

Serial number

Standard information – This

machine meets the requirements

of the standards mentioned here

CE mark – This machine con-

forms to the EU directives as per

declaration of conformity

Electrical performance data

Year of make

3.

Operating Elements

Welding current regulator

Carrying strap/shoulder strap

Adjustable in length for carrying

− by hand (shown in illustra-

tion)

− on the shoulder.

Master switch

switches the unit ON or OFF

Equipment-on indicator light

2

3

4

5

6

7

1

8

10

9

11

12

13

14

15

Fault indicator light

The LED flashes:

− in case of a low-voltage

condition

− in case of an over-voltage

condition

− in case of excessive an

operating temperature.

Selector switch

Manual Arc MMA – TIG DC

(lift-arc ignition)

Welding current socket (+ pole)

Welding current socket (– pole)

LED = Light-Emitting Diode, used as

indicator light.

4.

Preparing for Operation

5.

Operation

>20 cm