7. checking and replacing alternator belt, Section 8-7 – Miller Electric OM-494 User Manual

Page 42

OM-494 Page 38

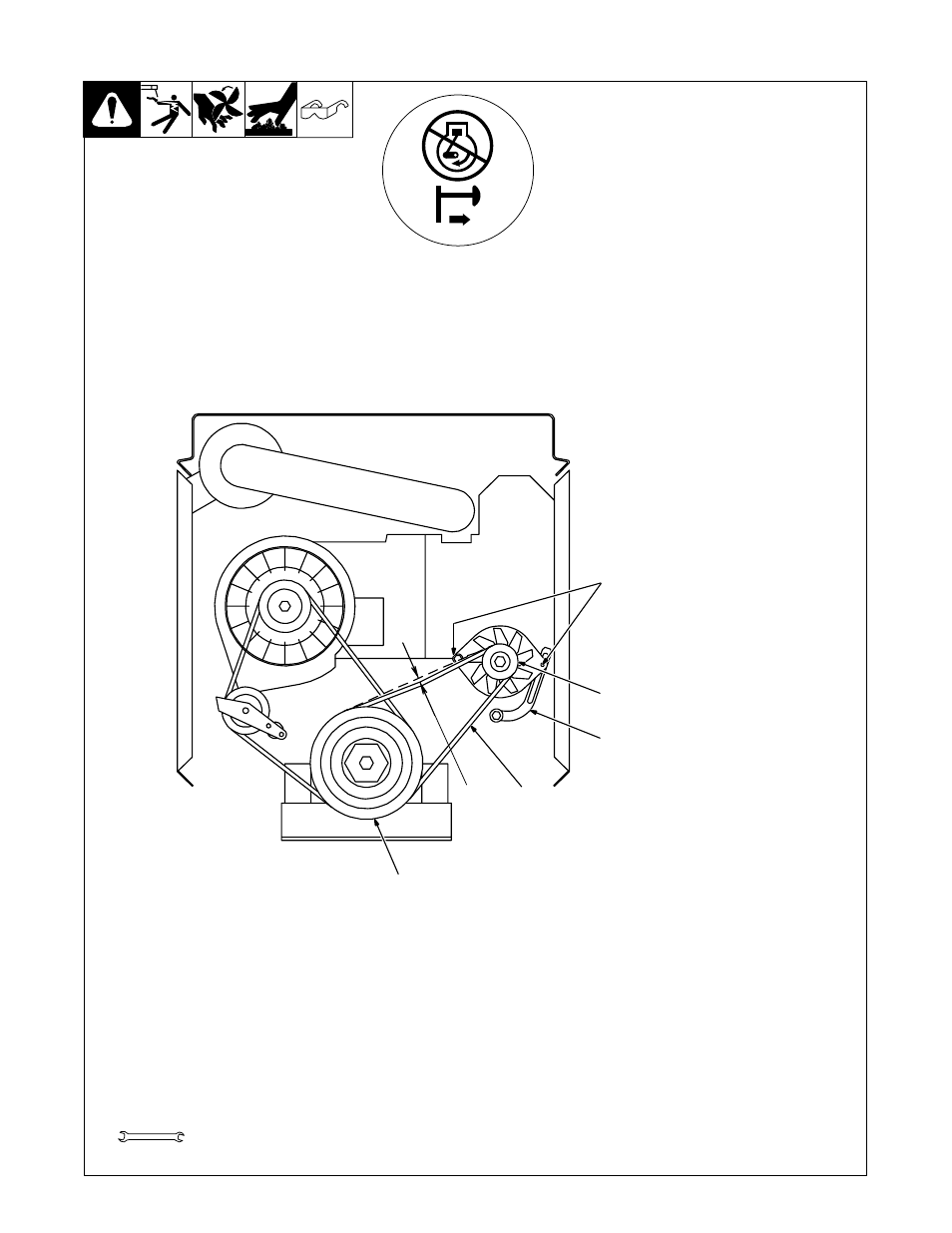

8-7. Checking And Replacing Alternator Belt

158 632 / Ref. 190 377

Y Stop engine.

To check belt tension:

Remove rear panel.

1

Alternator V-Belt

2

Crank Pulley

3

Alternator Pulley

Place straight edge along top of pul-

leys. Pull down belt as far as it will

go, then measure distance from

belt to straight edge.

If measurement is less than 1/2 in

(13 mm), belt is okay. If not okay,

adjust belt tension.

To adjust belt tension:

4

Hex Nuts (2)

5

Alternator Bracket

Loosen nuts. Pivot alternator until

belt is tight. Tighten nuts. Recheck

tightness of belt. Readjust if

necessary.

Replace belt if damaged or

cracked.

To replace belt:

Loosen hex nuts and pivot alterna-

tor clockwise. Remove belt.

Install new belt, pivot alternator until

belt is tight, and tighten nuts. Re-

check tightness of belt after running

engine 15 minutes.

Reinstall rear panel.

1

1/2, 11/16 in

1/2 in

(13 mm)

Max

4

3

5

2

Tools Needed:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)