Outdoor unit installation, 1. connecting wires for outdoor unit, 2. flare connection – MITSUBISHI ELECTRIC MSZ-FD09/12NA User Manual

Page 6

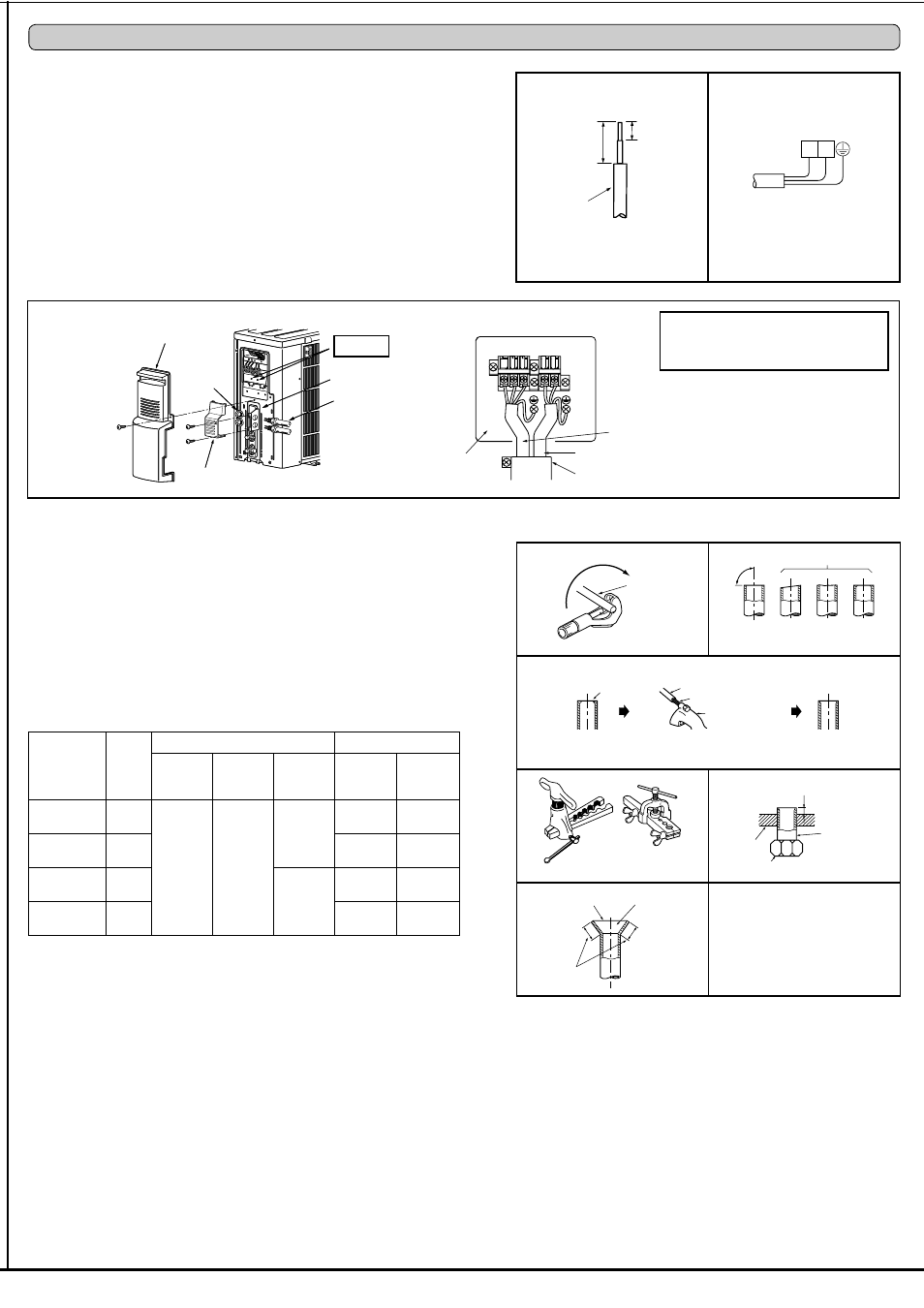

3-1. CONNECTING WIRES FOR OUTDOOR UNIT

1) Remove the service panel.

2) Remove the conduit cover.

3) Attach the conduit connector to conduit plate with lock nut then secure it against unit with

screws.

4) Connect ground wires of indoor/outdoor unit connecting wire (A) and power supply cord (K)

to the TB support.

5) Loosen the terminal screw, and attach indoor/outdoor unit connecting wire (A) from the indoor

unit correctly on the terminal block. Attach the wire to the terminal block securely so that its

core cannot be seen, and no external force affects the connecting section of the terminal

block.

6) Firmly tighten the terminal screws. After tightening, verify that the wires are tightly fastened.

7) Connect power supply cord (K).

8) Install the conduit cover.

9) Install the service panel securely.

3-2. FLARE CONNECTION

1) Cut the copper pipe as straight as possible with a pipe cutter. (Fig. 1, 2)

2) Remove all burrs from the cut section of the pipe, ensuring that precautions are taken to

avoid getting metal shavings into the piping. (Fig. 3)

5HPRYHÀDUHQXWVDWWDFKHGWRLQGRRUDQGRXWGRRUXQLWVWKHQSXWWKHPRQSLSH

4) Flaring work (Fig. 4, 5). Firmly hold copper pipe in the dimension shown in the table. Select A

mm from the table according to the tool you use.

5) Check

&RPSDUHWKHÀDUHGZRUNZLWK)LJ

,IÀDUHLVGHIHFWLYHFXWRIIWKHVHFWLRQDQGUHSHDWSURFHGXUH

Terminal block

Conduit cover

Lead wire

3. OUTDOOR UNIT INSTALLATION

Power supply cord (K)

Indoor/outdoor unit

connecting wire (A)

• Make earth wire a little longer than others.

(More than 2-3/8 in. [60 mm])

• For future servicing, leave some slack in

the connecting wires.

Pipe diameter

inch (mm)

Nut

inch

(mm)

A inch (mm)

Tightening torque

Clutch

type tool

for R410A

Clutch

type tool

for R22

Wing nut

type tool

for R22

N•m

ft•lb

(kgf•cm)

ø 1/4 (6.35)

1/4

(17)

0 to 0.02

(0 to 0.5)

0.04 to

0.06

(1.0 to

1.5)

0.06 to

0.08

(1.5 to

2.0)

13.7 to 17.7

10 to 13

(140 to 180)

ø 3/8 (9.52)

3/8

(22)

34.3 to 41.2

25 to 30

(350 to 420)

ø 1/2 (12.7)

1/2

(26)

0.08 to

0.10

(2.0 to

2.5)

49.0 to 56.4

36 to 42

(500 to 575)

ø 5/8 (15.88)

5/8

(29)

73.5 to 78.4

54 to 58

(750 to 800)

Power supply cord (K)

L1 L2

1-3/8 in.

(35 mm)

19/32 in.

(15 mm)

Service panel

Lock nut

Conduit cover

Conduit plate

Connector

Grounding

terminal

Copper

pipe

Good

90°

Tilted

No good

Fig. 1

Fig. 2

Burr

Copper pipe

Spare reamer

Pipe cutter

Fig. 4

Fig. 3

Smooth all around

Even length

all around

Inside is shin-

ing without any

scratches.

Fig. 5

Fig. 6

A

Flare nut

Die

Copper pipe

Clutch type

Flaring tool

Wing nut type

Uneven Burred

TB support