Edge jointing – Grizzly T10222 User Manual

Page 18

-16-

Model t10222 (Mfg. since 12/09)

Edge Jointing

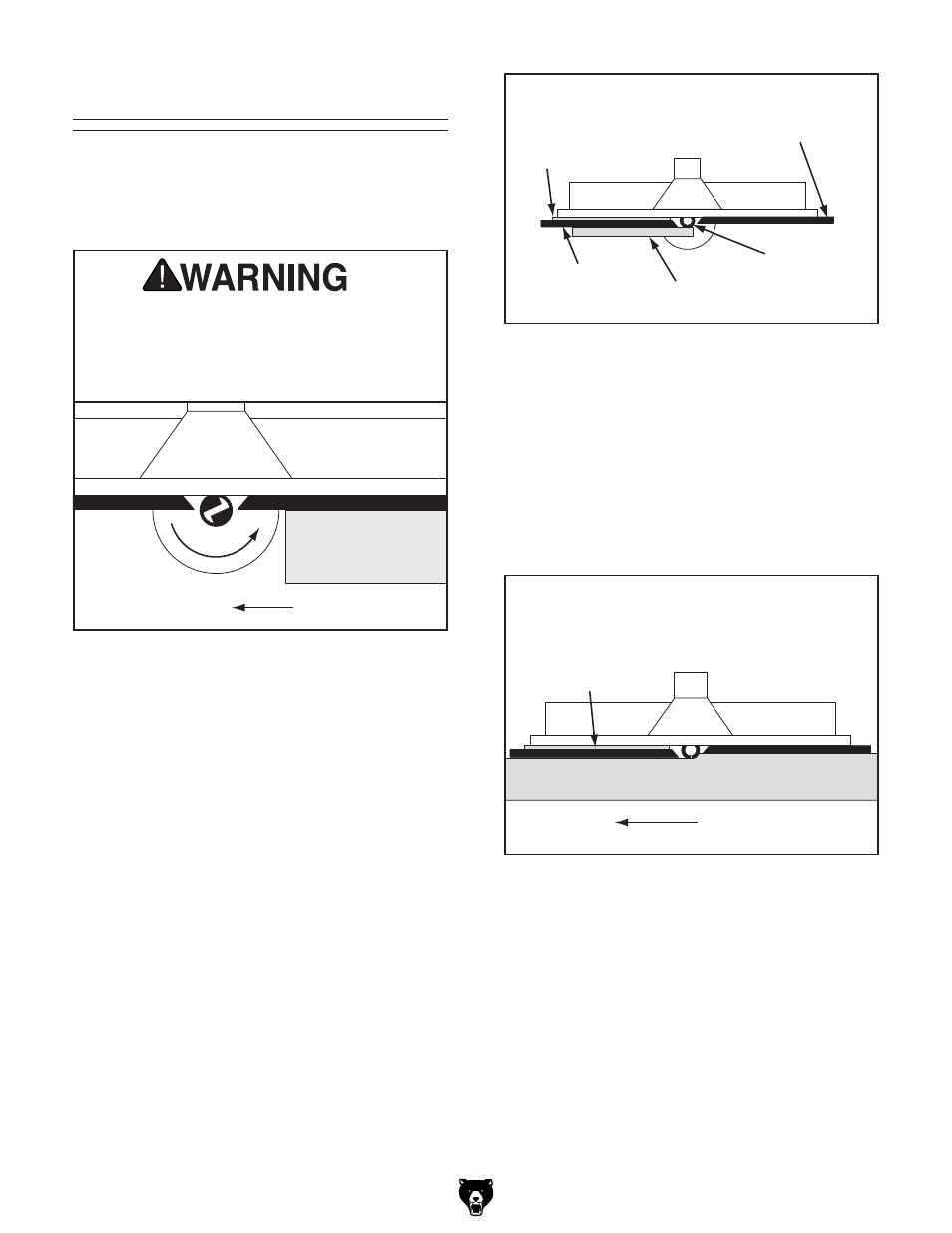

Jointing the edge of a board involves using a

straight cutting router bit to remove wood from the

face of the board. the result is a perfectly flat and

square edge.

To joint the edge of a workpiece:

1. disConnECt routEr FroM poWEr!

2. secure a straight cutting bit into your rout-

er according to the router manufacturer's

instructions.

3. install the smallest table insert into the router

table that still allows the router bit to freely

rotate.

4. raise the bit to a height slightly more than

that of the workpiece, then rotate it by hand

until the cutting flute is perpendicular to the

fence boards.

5. insert and secure shims between the outfeed

fence board and the fence bracket that equal

in thickness the amount of material you want

to remove from the workpiece face (see the

illustration in

figure 21).

Straightedge

Shim

Outfeed

Fence Board

Straight

Router Bit

Infeed

Fence Board

Top View

figure 21. Fence setup for edge jointing (guard

removed for clarity).

6. place a straightedge against the outfeed

fence board, then adjust the fence assembly

so that the straightedge is also against the bit

flute, as illustrated in

figure 21.

7. lock the fence assembly in place, tighten all

knobs, connect the router to power, then per-

form the cut (see

figure 22).

Top View

Cutting Direction

Shim

Workpiece

figure 22. Edge jointing (guard removed for

clarity).

Workpiece

Feed Direction

Bit

Rotation

Always feed the workpiece against the rout-

er bit rotation direction, as illustrated below.

Otherwise, the workpiece could be aggres-

sively pulled from your hands, drawing

them into the spinning cutter.