Fitting the starter, Air filter, Spark plug – Garmin TRIOBRAKE 353 User Manual

Page 34: Lubricating the bar tip sprocket, Needle bearing lubrication, Maintenance

MAINTENANCE

34 – English

•

Lubricate the recoil spring with light oil. Fit the

cassette with recoil spring in the starter. Fit the starter

pulley and tension the recoil spring.

Fitting the starter

•

To fit the starter, first pull out the starter cord and place

the starter in position against the crankcase. Then

slowly release the starter cord so that the pulley

engages with the pawls.

•

Fit and tighten the screws that hold the starter.

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

•

Carburettor malfunctions

•

Starting problems

•

Loss of engine power

•

Unnecessary wear to engine parts.

•

Excessive fuel consumption.

•

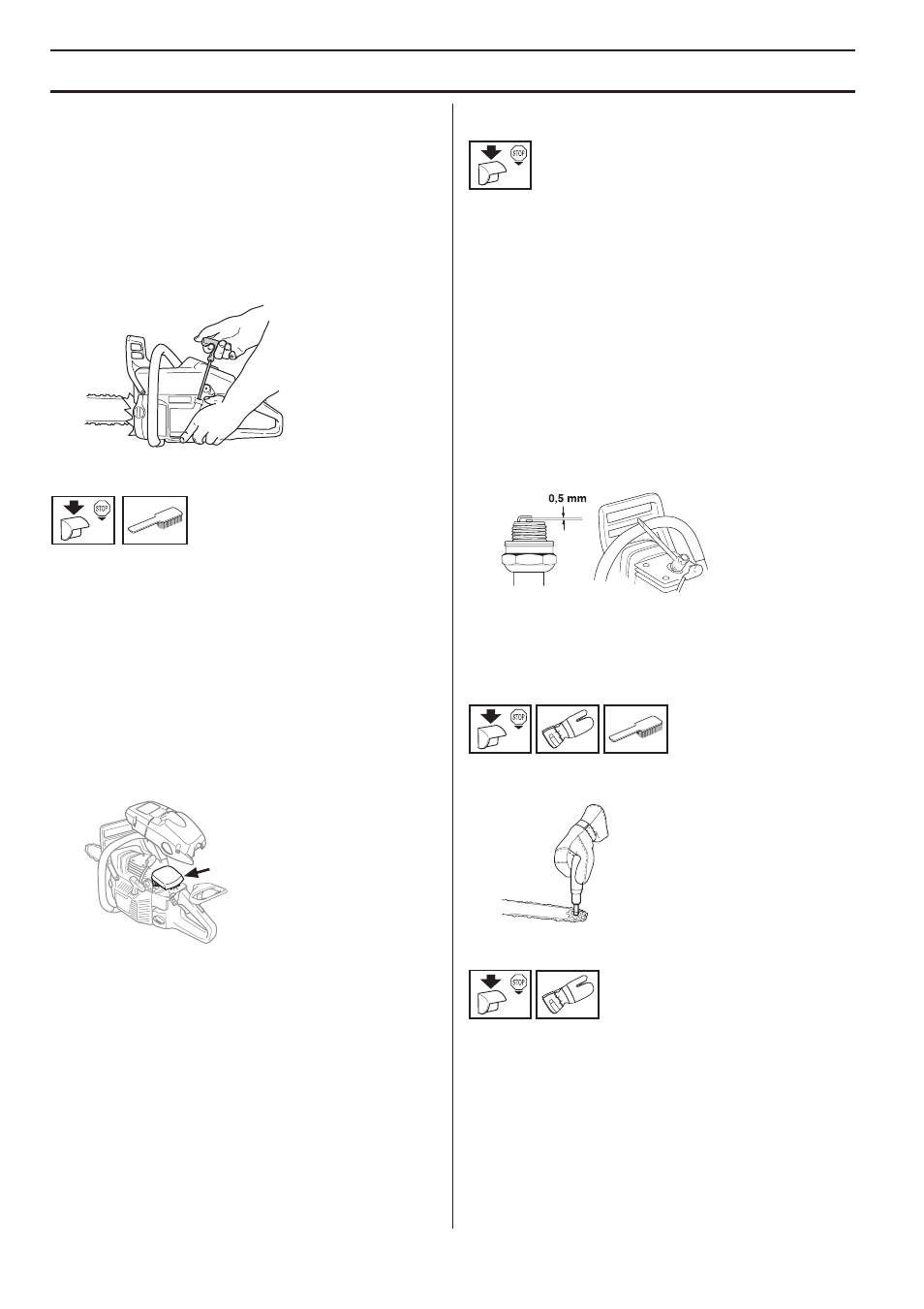

Remove the air filter after taking off the air filter cover.

When refitting make sure that the air filter seals tightly

against the filter holder. Clean the filter by brushing or

shaking it.

The filter can be cleaned more thoroughly by washing it in

water and detergent.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals. A damaged air filter

must always be replaced.

A HUSQVARNA chain saw can be equipped with different

types of air filter according to working conditions, weather,

season, etc. Contact your dealer for advice.

Spark plug

The spark plug condition is influenced by:

•

Incorrect carburettor adjustment.

•

An incorrect fuel mixture (too much or incorrect type

of oil).

•

A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0.5 mm. The

spark plug should be replaced after about a month in

operation or earlier if necessary.

Note! Always use the recommended spark plug type! Use

of the wrong spark plug can damage the piston/cylinder.

Check that the spark plug is fitted with a suppressor.

Lubricating the bar tip sprocket

Lubricate the bar tip sprocket each time you refuel. Use

the special grease gun and a good quality bearing grease.

Needle bearing lubrication

The clutch drum has a needle bearing on the output shaft.

This needle bearing must be lubricated regularly (once a

week).

When lubricating, remove the clutch cover by loosening

the two bar nuts. Lay the saw on its side with the clutch

drum upwards.