Troubleshooting chart – Goodmans ASX User Manual

Page 33

33

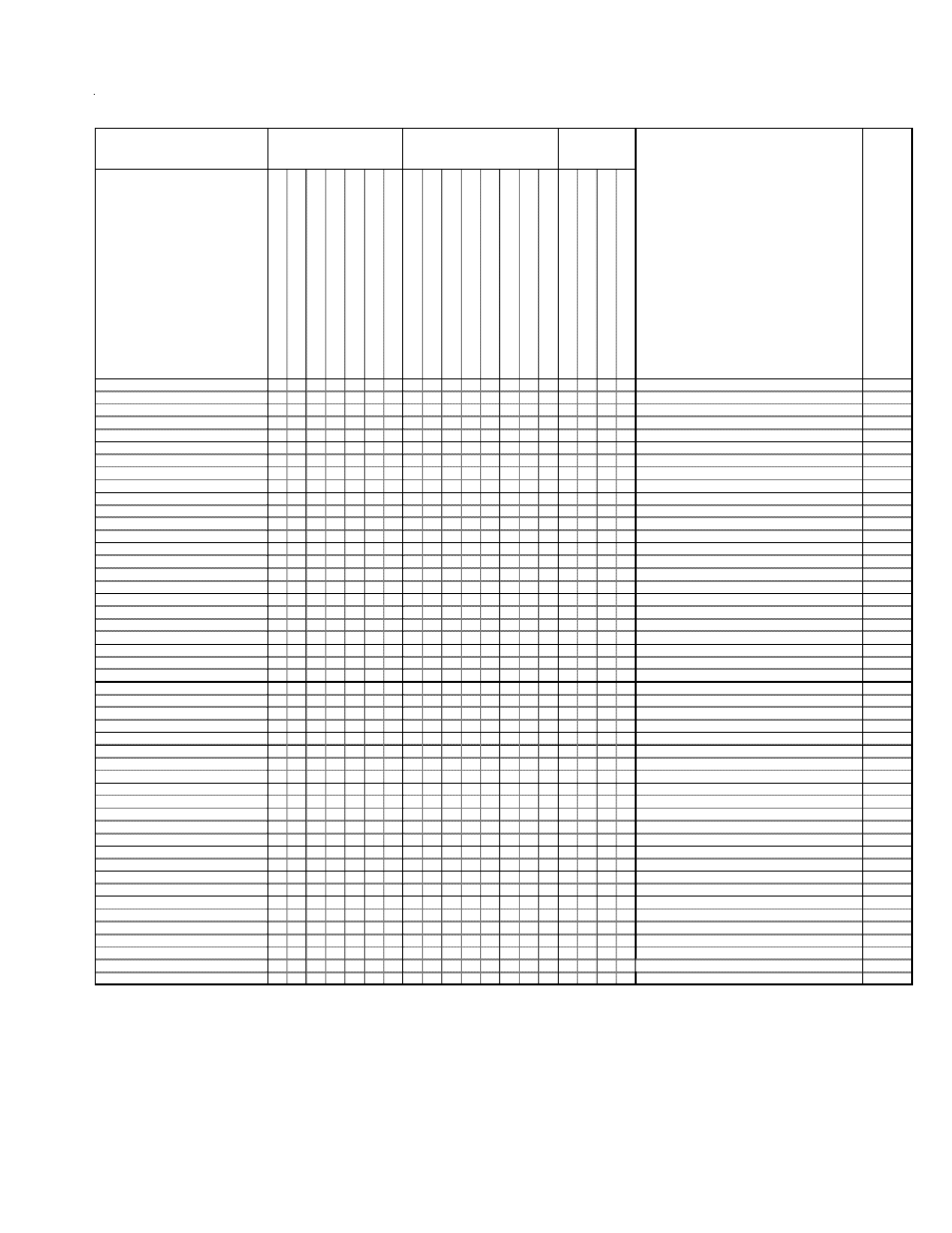

TROUBLESHOOTING CHART

Co m p lain t

Sys te m

Op e r atin g

Pr e s s ur e s

P OS SIBLE CAUSE

DOTS IN ANALYSIS

GUIDE INDICATE

"P OS SIBLE CAUSE"

SYMPTO

M

Syste

m

will n

o

t sta

rt

Co

m

p

re

sso

r will n

o

t sta

rt -

fa

n

r

u

n

s

Com

p

. and Cond. F

an will

not star

t

E

v

apor

ator

fan

will not star

t

Condenser

fan w

ill not star

t

Com

p

ressor runs - goes off on overl

oad

Com

p

re

ssor

cycles on over

load

S

ystem

runs conti

nuousl

y

- l

it

tl

e cool

ing/htg

T

oo cool

and then too warm

Not cool

enough on warm

days

Certai

n areas too cool

, others too warm

Com

p

re

ssor

is noisy

S

ystem

runs - bl

ows col

d

ai

r i

n

heati

n

g

Un

it will n

o

t te

rm

in

a

te

d

e

fr

o

st

Un

it will n

o

t d

e

fr

o

st

Low sucti

on pressure

Low head pressure

Hi

gh sucti

on pressure

Hi

gh head pressure

Te st Me thod

Re m e dy

S

ee S

e

rvi

ce P

rocedure R

e

f.

Pow er Failure

•

Test V oltage

S-1

Blow n Fus e

•

• •

Ins pec t Fuse Siz e & Ty pe

S-1

Unbalanced Pow er, 3PH

•

• •

Test V oltage

S-1

Loose Connec tion

•

•

•

Ins pec t Connec tion - Tighten

S-2, S-3

Shorted or Broken Wires

• • • • • •

Test Circ uits With Ohmmeter

S-2, S-3

Open Fan Ov erload

• •

Test Continuity of Ov erload

S-17A

Faulty Thermos tat

•

• •

•

Test Continuity of Thermos tat & Wiring

S-3

Faulty Transf ormer

•

•

Chec k Control Circuit w ith V oltmeter

S-4

Shorted or Open Capacitor

•

• • • •

Test Capacitor

S-15

Internal Compres s or Overload Open

•

♦

Test Continuity of Ov erload

S-17A

Shorted or Grounded Compress or

•

•

Test Motor Windings

S-17B

Compress or Stuc k

•

• •

♦

Us e Test Cord

S-17D

Faulty Compress or Contactor

•

• •

Test Continuity of Coil & Contac ts

S-7, S-8

Faulty Fan Relay

•

Test Continuity of Coil A nd Contac ts

S-7

Open Control Circ uit

•

Test Control Circ uit w ith V oltmeter

S-4

Low V oltage

•

• •

Test V oltage

S-1

Faulty Evap. Fan Motor

•

•

♦

Repair or Replac e

S-16

Shorted or Grounded Fan Motor

•

•

Test Motor Windings

S-16

Improper Cooling A ntic ipator

•

•

Chec k Resis tanc e of A ntic ipator

S-3B

Shortage of Ref rigerant

• •

♦

• •

Test For Leaks, A dd Ref rigerant

S-101,103

Res tric ted Liquid Line

• •

• •

•

Remov e Res tric tion, Replac e Restricted Part

S-112

Open Element or Limit on Elec . Heater

♦

♦

Test Heater Element and Controls

S-26,S-27

Dirty A ir Filter

•

• •

•

♦

Ins pec t Filter-Clean or Replace

Dirty Indoor Coil

•

• •

•

♦

Ins pec t Coil - Clean

Not enough air ac ros s Indoor Coil

•

• •

•

♦

Chec k Blow er Speed, Duc t Static Pres s, Filter

S-200

Too much air across Indoor Coil

♦

•

Reduc e Blow er Speed

S-200

Ov erc harge of Ref rigerant

• •

•

♦

• •

Recov er Part of Charge

S-113

Dirty Outdoor Coil

• •

•

♦

•

Ins pec t Coil - Clean

Noncondensibles

•

•

♦

•

Recov er Charge, Ev ac uate, Recharge

S-114

Rec irc ulation of Condens ing A ir

•

•

•

Remov e Obs truc tion to A ir Flow

Inf iltration of Outdoor A ir

•

• •

Chec k Window s , Doors , V ent Fans , Etc.

Improperly Loc ated Thermos tat

•

•

Reloc ate Thermostat

A ir Flow Unbalanc ed

•

•

Readjust A ir V olume Dampers

Sy s tem Unders iz ed

•

•

Ref igure Cooling Load

Broken Internal Parts

•

♦

Replac e Compres sor

S-115

Broken V alves

•

•

• •

Test Compres sor Ef f icienc y

S-104

Inef f ic ient Compress or

•

♦

• •

Test Compres sor Ef f icienc y

S-104

Wrong Ty pe Ex pans ion V alv e

• • •

•

• •

♦

Replac e V alv e

S-110

Ex pans ion Dev ice Res tric ted

• • •

•

• •

•

Remov e Res tric tion or Replace Ex pans ion Devic e

S-110

Ov ers iz ed Ex pans ion V alve

•

•

Replac e V alv e

Unders ized Ex pansion V alv e

• • •

•

•

Replac e V alv e

Ex pans ion V alve Bulb Loos e

•

•

Tighten Bulb Brac ket

S-105

Inoperativ e Ex pansion V alve

•

•

•

Chec k V alve Operation

S-110

Loose Hold-dow n Bolts

•

Tighten Bolts

Faulty Rev ers ing V alv e

•

♦ ♦ ♦

♦ ♦ ♦

Replac e V alv e or Solenoid

S-21, 122

Faulty Def ros t Control

•

♦ ♦ ♦ ♦ ♦

♦

Test Control

S-24

Faulty Def ros t Thermostat

♦ ♦ ♦ ♦ ♦ ♦ ♦

Test Def rost Thermostat

S-25

Flow rator Not Seating Properly

•

• •

Chec k Flow rator & Seat or Replac e Flow rator

S-111

•

Co olin g o r He ating Cycle (He at Pu m p )

♦

C OOLIN G/H P AN ALYS IS C H AR T

No Co oling

Un s atis facto r y

Coo lin g /He ating

He atin g Cycle Only (He at Pu m p )