Mounting to a workbench – Global Machinery Company BS230L User Manual

Page 9

9

Note.

It may be necessary to rotate the handle

anticlockwise to be able to slide the rip fence over the table

and then clockwise before locking the handle in position.

5. Attach the mitre gauge (30) onto the table by sliding it into

the mitre gauge slot.

6. Screw the push stick screw and nut into the hole at the

rear of the saw (next to the push stick storage area).

Mounting to a

workbench

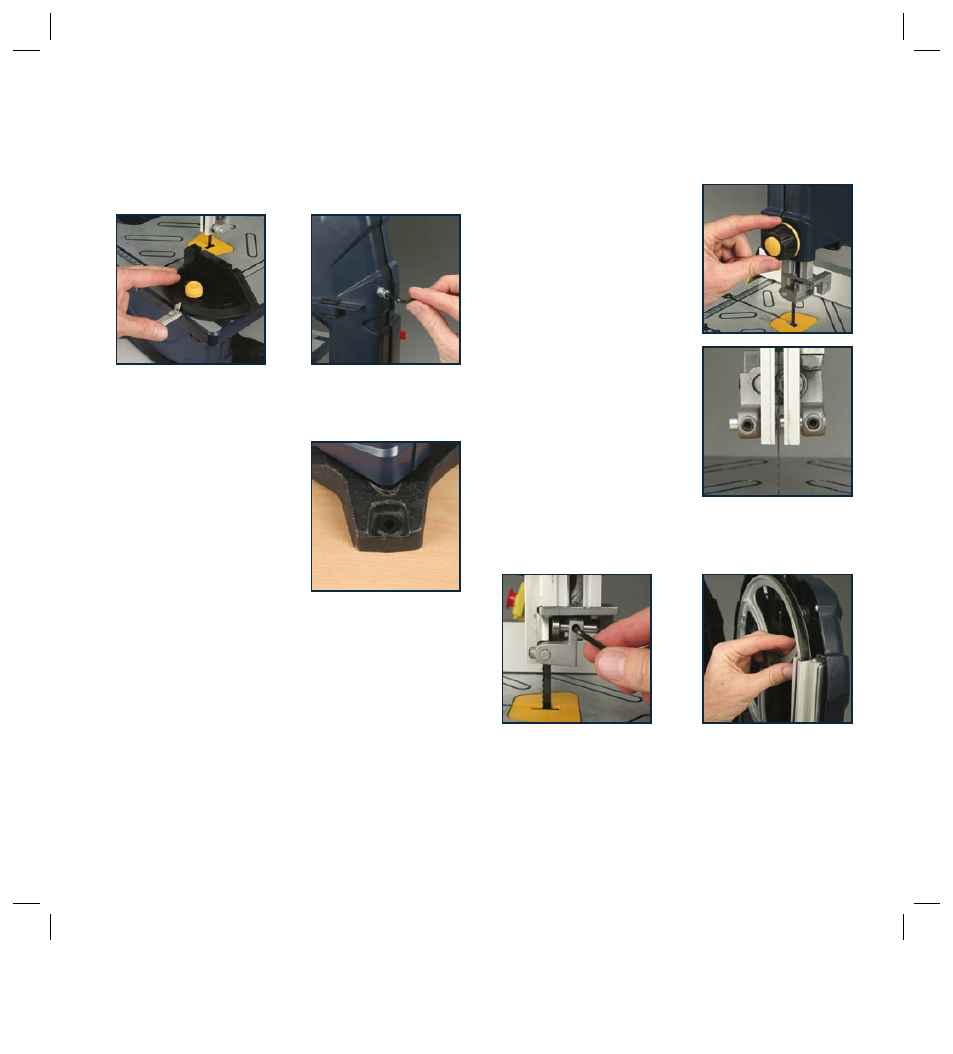

1. The band saw features four

holes in the base for mounting

to a workbench.

2. It is best to attach the band

saw to a firm, stable surface

at a convenient working

height. A workbench is ideal.

3. Drill four holes in the workbench to match the four holes

in the base of the saw.

4. Attach the band saw to the work bench using bolts

(inserted from the top), lock washers and nuts

(not supplied).

Upper blade guide adjustment

WARNING.

Always ensure that the saw is switched

off and unplugged from the power supply before making

any adjustments.

1. The upper blade guide (20) protects against unintentional

contact with the saw blade.

2. In order for the upper blade guide to provide adequate

protection against contact with the band saw blade (25),

it must always be set as close as possible against the

workpiece (maximum distance 3mm).

3. To adjust the height of the

upper blade guide rotate the

blade guide knob (21). Rotate

in a clockwise direction to

move the blade guide up,

rotate in an anti-clockwise

direction to move the blade

guide down.

4. The upper blade guide

consists of a thrust bearing

that supports the band saw

blade from the rear and two

guide pins that provide

lateral support, these need

to be readjusted after every

band saw blade change or

tracking adjustment.

Thrust bearing adjustment

1. To adjust the thrust bearing loosen the thrust bearing

locking screw using the 3mm hex key (36) supplied.

2. Adjust the thrust bearing position until it is 0.5mm

away from the band saw blade. When the band saw

blade is turned by hand it should not make contact with

the thrust bearing.

3. Tighten the thrust bearing locking screw.