9 additional information – Generac Power Systems 004701-0 User Manual

Page 11

9

Section 2 – Operation

Recreational Vehicle Generator

2.8.2 HIGH TEMPERATURE SWITCH

This switch (Figure 2.2), which has normally open

(N.O.) contacts, is mounted near the oil filter. The

contacts close if the temperature should exceed

approximately 284º F (140º C), initiating an engine

shutdown.

Figure 2.2 – Low Oil Pressure and

High Temperature Switches

High Temperature Switch

Low Oil Pressure

Switch

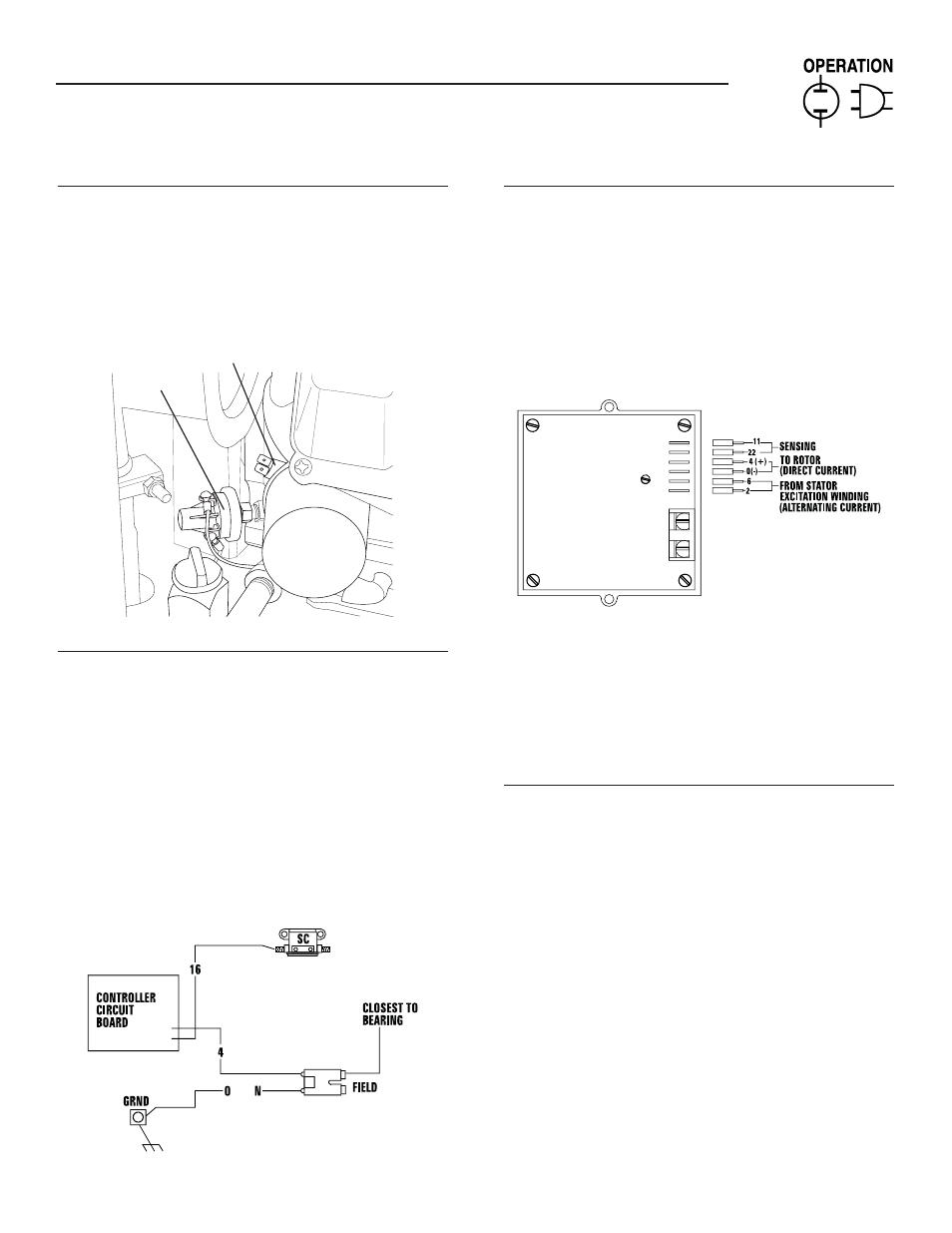

2.8.3 FIELD

BOOST

The Controller Circuit Board houses a field boost

diode and resistor that are not part of the automatic

choke circuit. These two components are part of

a “field boost” circuit (Figure 2.3). During engine

cranking only, a positive DC (battery) voltage is

delivered through the diode, resistor, brushes and

slip rings, to the generator rotor. Application of this

voltage to the rotor “flashes the field” whenever it is

started. Flashing of the field each time the generator

starts makes sure that a sufficiently strong magnetic

field is available to produce “pickup” voltage in the

stator windings.

Figure 2.3 – Field Boost Circuit

2.8.4 OVERVOLTAGE PROTECTION

A solid-state voltage regulator (Figure 2.4) controls

the generator’s AC output voltage. This regulator sup-

plies an excitation current to the rotor. By regulating

the rotor’s excitation current, the strength of its mag-

netic field is regulated and, in turn, the voltage deliv-

ered to connected electrical loads is controlled. When

the AC frequency is 60 Hertz, voltage is regulated at

120 volts (voltage-to-frequency ratio is 2-to-1).

Figure 2.4 – Solid State Voltage Regulator

The voltage regulator also incorporates a “voltage

surge protection circuit.” This circuit prevents trou-

blesome surges in the generator AC output voltage.

Voltage surge is a common cause of damage to elec-

tronic equipment.

2.9 ADDITIONAL INFORMATION

2.9.1 25-HOUR BREAK-IN PERIOD

The first 25 hours of operation is the break-in period

for the generator. Properly breaking in the genera-

tor is essential to minimize fuel consumption and

provide maximum engine performance. During this

25-hour break-in period, follow this procedure:

• Run the unit at varying electrical loads to help seat

the engine piston rings properly.

• Check the engine oil level frequently. Add oil if

needed. It is normal for the generator engine to

consume more oil than is normal until the piston

rings have properly seated.

• For the 75-hour operation following the break-in

period, avoid light electrical loads. Load the gen-

erator at 50 percent (or more) of its rated watt-

age capacity. Repeated light loads during these 75

hours can cause improper seating of engine piston

rings, resulting in blowby and high oil consump-

tion.

• After operating the unit for 25 hours, complete the

tasks recommended under "25-Hour Check-up".