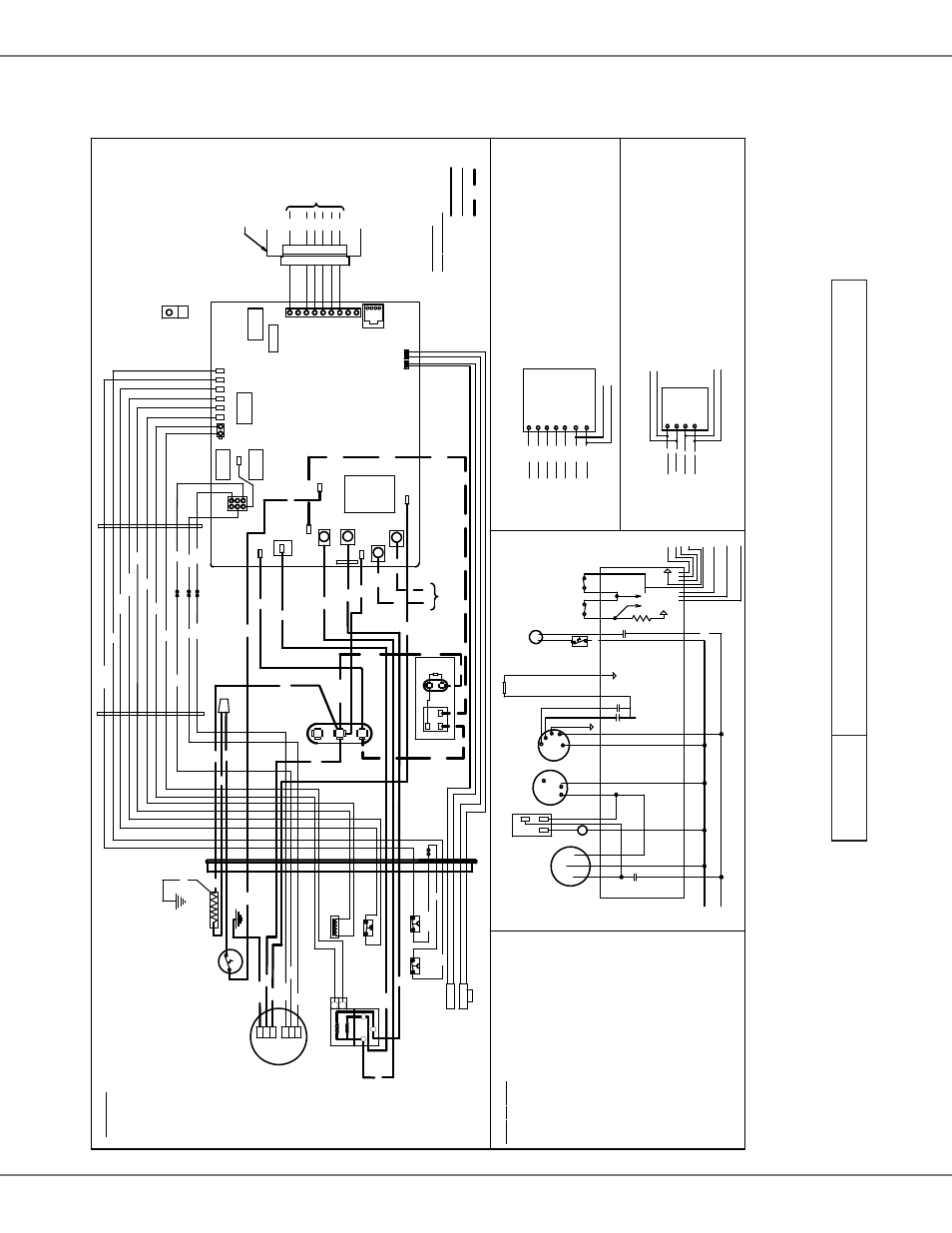

Wiring diagram, Dszc18 w, La b el , w iring diagram – Goodman Mfg SS-DSZC18 User Manual

Page 23: The good ma n ma nufa c tu ring co mpan y, l.p, Iring, Iagram, Spec ia l ch ar ac ter ist ics, Roduct, Pecifications, 6sigma

22

www.goodmanmfg.com

SS-DSZC18

SS-DSZC18

www.goodmanmfg.com

23

P

roduct

S

PecificationS

P

roduct

S

PecificationS

DSZC18 w

iRing

D

iagRam

8

7

65

4

21

3

8

76

5

4

21

3

E

D

B

A

C

E

D

B

A

C

CONF

IDENT

IAL

PR

OPERT

Y OF

THE

GO

ODMAN

M

ANUFACT

URI

NG

COMPA

NY

, L

.P.

NOT

TO

BE D

ISCL

OSED

TO

OT

HERS,

C

OPIED

, OR

U

SED F

OR

AN

Y PURPOSE

EXCEPT

AS

AU

THOR

IZED

IN W

RIT

ING.

M

UST

BE

RET

URNED

U

PON DE

MAND,

O

N C

OMPLET

ION

OF O

RDER,

O

R

OTHER

P

URPOSE

FO

R

WHI

CH

IT

WA

S LE

NT.

COMP

ONENTS

AN

D

MATER

IALS

SPE

CIF

IED HER

EIN

W

ILL

ALS

O

CONFO

RM TO

THE

APPL

ICABLE

SE

CTIO

N

OF

GOOD

MAN

M

SP 8

24.0

1 W

ORKMA

NSHIP

STANDAR

D.

SPEC

IA

L

CH

AR

AC

TER

IST

ICS:

=

6SIGMA

=

CR

ITI

CAL

CHARACTERISTI

C

=

SIGNIFI

CANT

CHARACTERISTI

C

SC

CC

6s

LA

B

EL

, W

IRING DIAGRAM

DATE: 08-30-10

ENG:

RT

DW

N BY

: G

L-S

P

DO NOT SCALE DRAWING

01

40R00

19

2

A

REV

C

H

K BY:

SK

SHT 1

OF 2

THE GOOD

MA

N MA

NUFA

C

TU

RING

CO

MPAN

Y, L.P.

TOLERANCES:

ANG

LES ± 1.5°

.X : ± .1

.XX : ± .0

3

.XXX : ± .015

HOLE Ø : ± .005

TU

BE C

U

T LG: ± .063

DRAWIN

G TO BE INTE

RPRETED IN

ACCORDANCE WITH AS

ME Y14.100

DI

ME

NSION

S ARE IN INCHE

S

UNLES

S OTHERWISE NOTED

EC

N

REV

DESCRIPT

ION

CHK

DR

DATE

100

5178

A

G

L-

PS

09-02-1

0

IN

ITIAL RELE

ASE

ZON

E

-

NO

TE

S:

1) MA

TERIA

L:

4 MIL WHI

TE FL

E

XIB

LE VINYL

WI

TH PRE

S

SURE

S

ENSI

TIVE P

ERMANEN

T ACRYLIC ADHESI

VE

AS PER S

P

EC. S

4900

061, TYP

E A

2)

TE

XT

TO

BE

BLACK

ON

WHI

TE

BACK

GROUND.

3) T

HE L

A

BE

L IS

TO BE PRO

VIDED IN ROL

L FORM.

4) T

HE DIREC

TION OF ROL

L F

E

ED (ARROW P

OIN

TING FROM LEF

T T

O RIGH

T).

WIRIN

G CODE

FAC

TORY

WIRIN

G

HIGH VOL

TAGE

LO

W V

OL

TAGE

HIGH VOL

TAGE

FIELD

CO

LO

R

CO

D

E

BK -----

----

----

-- BLACK

BL ---

----

----

----

BLUE

BL/PK ----

----

-- BLUE/PINK S

TRIPE

BR ----

----

----

--- BROWN

OR -----

----

----

-- ORANGE

PU ----

----

----

--- PURPLE

RD ---

----

----

----

RED

WH -------

----

--- WHI

TE

YL -----

----

----

-- YELLO

W

YL/PK ------

----

YELLO

W/PINK

STRIPE

1

3

4

6

E11

E16

COM

FAN

HERM

GR/YL

BL

BR

RELAY

RELAY

RELAY

HERM

COM

STAR

T

RUN

230 VAC SUPPLY

L1

L2

E13

L2 OU

T

L2

L1

E10

R

C

S

TA

RT

E5

E8

CAP COM

CCH

E21

E17

ST

AR

T

RLY

WH

UC BOARD

FUSE

O L

R

C

W1

Y1

E2

Y2

FAN RUN

RELAY

RELAY

1

2

E29

E28

E26

E24

E23

E22

E14 HIGH

RVS

LPCO

HPCO

E47

E1

OA

T

O

CT

OAS

OCS

(HEA

T PUMP ONLY)

WH

BL

BL WH

YL

BK

YL

BR

GND

LO

W

V

O

LT

A

G

E

B

ARR

IER

BL/PK

BK

YL/PK

BK

YL/PK

BK

RD

BK

BK

BK

BL/PK

RCCF

C

R

S

A

UX

M

A

IN

C

O

M

P

CS

Y2

C

BK

YL

RD

CON

TROL BOX

O

L Y2 Y1 W1 C

O

L (OP

TIONAL)

Y2

Y1 W1

C

LEGACY

IND

OOR THERMOS

TAT

C

R 2 1

C R 2

1

R

R

C

INDOOR P

O

W

ER SUPPLY

24 VAC

COM

MUNICATING INDO

OR

THERMOS

TAT

INDOOR P

O

W

ER SUPPLY

24 VAC

TO INDOOR C

OMMUNICATING PCB

THIS WIRIN

G SCHEMA

TIC SHO

W

S THE LEGAC

Y

WIRIN

G FROM

THE FAC

TORY.

THE WIRE

S GO TO INDOOR

THERMOS

TAT

AS

SHOWN IN "LEG

ACY INDO

OR

THERMOS

TAT

".

TO

WIRE

THE

SYS

TEM IN CO

M

MUNICATING MODE,

THE INS

TALLER HAS

TO

W

ORK

THE

WIRIN

G

AS

SHO

WN

IN

"COMMUNICATING

IND

OOR

THERMOS

TAT". REFER T

O

THE IO MANUAL LOCA

TED IN

COM

MUNICATING

THERMOS

TAT KIT

FOR MORE DET

AILS.

FROM OUTDOOR UNI

T

GND L1 L2

BK

YL

YL

CM

RES

2

5

1

SR

SC

OP

TIONAL HARD S

TAR

T

L1

L2

K2

C

R

S

CO

MP

R

S

1

2

5

HERM

C

CCH

SC

C

UC CONT

RO

L

HERM

CAP COM

SR

LPC

HPC

E14

TO

UP

OP

TIO

NAL HA

RD

START

RUN

CAPACITO

R

12

R

C

Y1

Y2

W1

O

K6

FAN

ECM F

AN

MOT

OR

C

HIG

H/L

OW

ON/OF

F

24V

K3

K4

CAPACITY

SOLE

NOID

VALVE

RD

CHS

RD

CH

BK

BK

CHS

RD

RD

RD

BK

RD

YL

BK

RD

0140R001

92 -A

RD

BL

WH

PU

YL

OR

FROM OUTDOOR UNI

T

R

GR/YL

BK

1 2

R

C

E25

RD

LPS

HPS

RVS

COM

PO

N

EN

T

CO

D

E

C ---

----

----

----

CON

TAC

TOR

CH ---

----

----

-- CRANKCASE HEA

TER

CHS----

----

----

CRANKCASE HEA

TER S

WI

TCH

CM

----

----

----

CONDENSER FAN MOT

OR

COMP --

----

-- COMPRESSOR

CS ----

----

----

- COMPRESSOR SOLENOID

D

T ---

----

----

-- DISCHARGE

THERMOS

TA

T

HPS ----

----

--- HIGH PRESSURE SWI

TCH

IO -----

----

----

- INTERNAL OVERLOAD

LPS ---

----

--- LOW PRESSURE SWI

TCH

OAS ------

----

- OU

TDOOR AIR SENS

OR

OCS

---

---

---

---

OU

TDO

OR

C

O

IL

T

EMP

SEN

SOR

RCCF --

----

--- RUN

CAPACI

TOR FOR COMPRESSOR & FAN

RVS ----

----

--- REVERSING VALVE SOLEN

OID

SC ----

----

----

- STAR

T CAPACI

TOR FOR COMPRESSOR (OP

TIONAL)

SR ----

----

----

- STAR

T RELAY FOR COMPRESSOR (O

PT

IONAL)

DT

SEE NO

TE 1

SEE NOTE 1

N

O

TE

:

1. USE COPPER SUPPL

Y

WIRE

S ONLY.

2.

USE

40VA

TRANSFORMER

MINI

MU

M

FOR

SYS

TEM

3. IF DT IS NOT PRESENT, HPS BL/PK

WIRE

GOES DIREC

TLY TO

TERMINAL E29

.

4. CON

TROLS SHO

WN

WI

TH

THERMOS

TA

T IN "OFF" POSI

TION.

5. COMMON SIDE OF 24VAC CON

TROL CIRCUI

T MUST BE

GROUNDED.

SEE NOTE 1

TO FIELD LO

W

VOL

TAGE

CON

TROL

WIRE

S. SEE

NO

TES 2 AND 5

6.

00

±.1

0

LABEL O

.D

.

5.

50

±.1

0

FRAME O

.D

.

9.00

±.1

0

LABEL O

.D.

8.50

±.1

0

FRAME O

.D.

Wiring

is

subject

to

chang

e.

Alw

ay

s

re

fer

to the wiring diagr

am or the

unit

for the mos

t up-t

o-da

te

wiring.

⚠

W

ARNING

High

Volt

ag

e:

Disc

onn

ect

all

po

w

er

be

for

e

ser

vicing

or

in

st

alling

this

unit.

Multiple

po

w

er

sour

ces

ma

y

be

pr

esen

t.

Failur

e

to

do

so

ma

y

cause

pr

operty

damag

e,

per

sonal

injur

y,

or

dea

th.

⚡