Selecting turning tools – Grizzly H8259 User Manual

Page 20

-18-

H8259 10" x 18" Benchtop Lathe

•

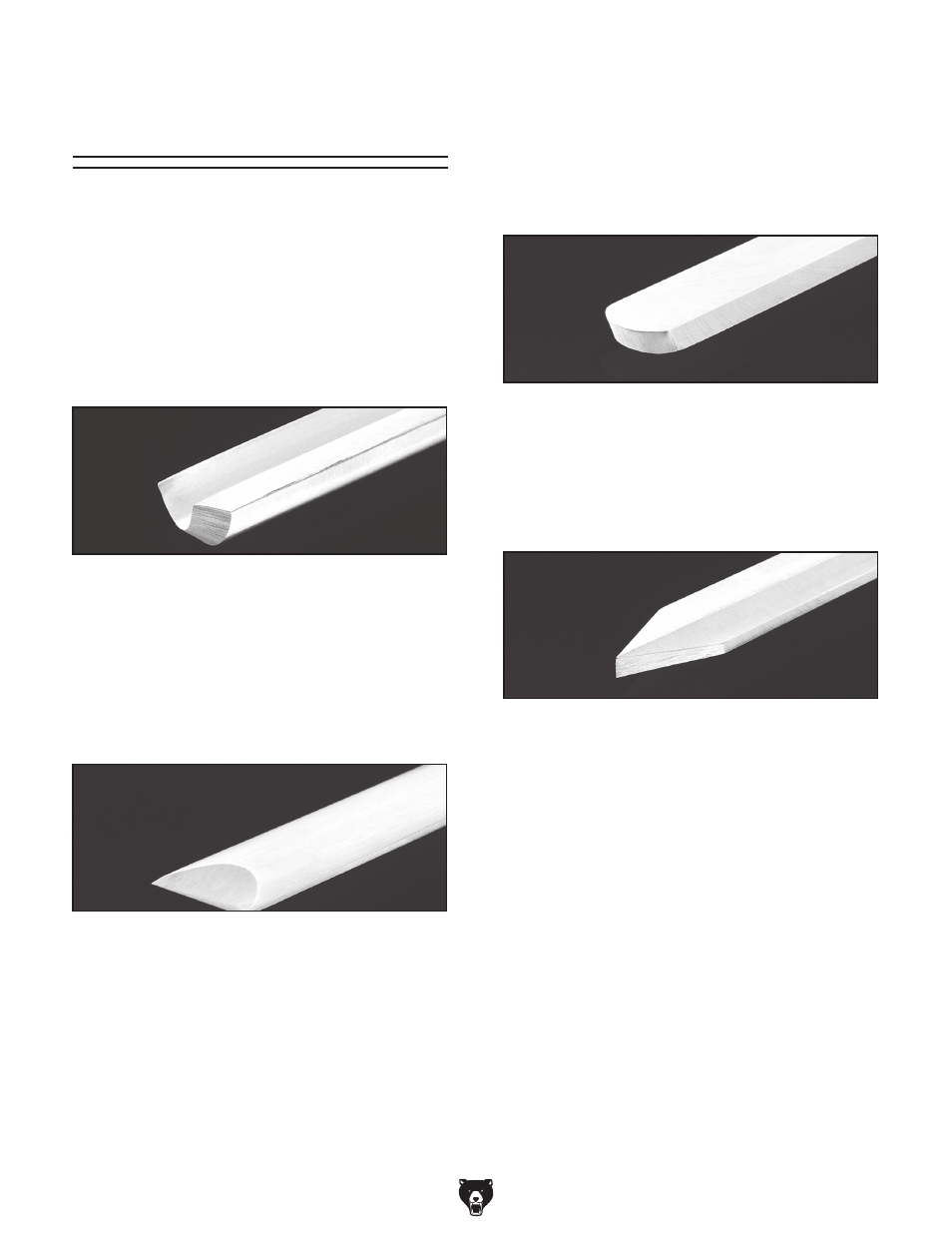

Scrapers—Mainly used where access for

other tools is limited, such as hollowing oper-

ations. This is a flat, double-ground tool that

comes in a variety of profiles (Round Nose,

Spear Point, Square Nose, etc.) to match

many different contours.

Figure 21 shows an

example of a round nose scraper.

Figure 21. Round nose scraper.

Figure 22. Parting tool.

•

Parting Tools—Used for sizing and cut-

ting off work. This is a flat tool with a sharp

pointed nose that may be single- or double-

ground.

Figure 22 shows an example of a

parting tool.

•

Specialty Tools—These are the unique,

special function tools to aid in hollowing, bowl

making, cutting profiles, etc. The Swan Neck

Hollowing Tool shown on

Page 23 is a good

example of a specialty tool.

Selecting Turning

Tools

Lathe tools come in a variety of shapes and sizes

and usually fall into five major categories.

•

Gouges—Mainly used for rough cutting,

detail cutting, and cove profiles. The rough

gouge is a hollow, double-ground tool with

a round nose, and the detail gouge is a hol-

low, double-ground tool with either a round or

pointed nose.

Figure 19 shows an example

of a gouge.

Figure 19. Gouge.

•

Skew Chisel—A very versatile tool that can

be used for planing, squaring, V-cutting,

beading, and parting off. The skew chisel

is flat, double-ground with one side higher

than the other (usually at an angle of 20-

40˚).

Figure 20 shows an example of a skew

chisel.

Figure 20. Skew chisel.