Operation, Variable shade, On" switch – Grizzly Auto Darkening Welding Helmet DD7542 User Manual

Page 4: Sensitivity dial

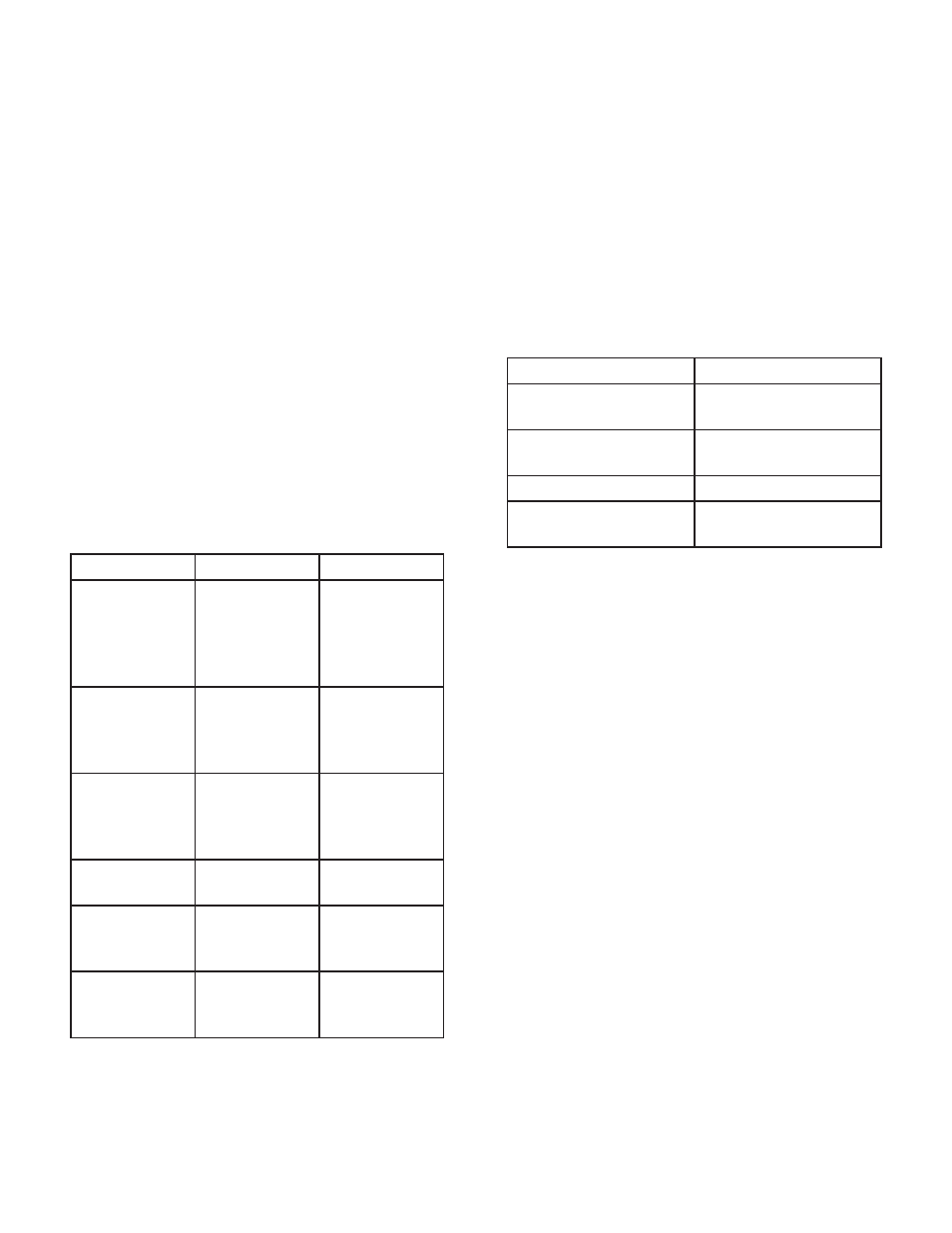

Variable Shade

The shade chart below shows settings that can

be used for various welding processes. We rec-

ommend that you start ANY welding process at

#12 or #13 and reduce the shade as needed for

safety.

"ON" Switch

Push the "ON" button on the side of the helmet.

The auto darkening feature will activate and stay

active for 15 minutes after the last bright light.

You will need to push the button again when this

occurs. Before welding raise the helmet up to a

bright light source and make sure the auto dark-

ening feature activates. If it does not, push the

button and check again. If it still does not work

see the troubleshooting guide at the end of this

instruction sheet.

Operation

Welding App. Current Amp.

Shade No.

Stick Welding

<40

40-80

80-175

175-300

300-500

#9

#10

#11

#12

#13

MIG

(metal inert

gas)

<100

100-175

175-300

300-500

#10

#11

#12

#13

TIG

(tungsten inert

gas)

<50

50-100

100-200

200-400

#10

#11

#12

#13

Air Carbon

Arc

<500

500-700

#12

#13

Plasma

Cutting

60-150

150-250

250-400

#11

#12

#13

Plasma

Welding

<50

50-200

200-400

#9

#10

#11

Sensitivity Dial

As previously mentioned, the auto darkening

lense can be made more sensitive or less sensi-

tive to bright light produced by welding. In most

applications, the dial should be set to middle of its

range. However, the setting should be changed

when used in extreme conditions. Below is a list

of applications and settings that you can use as a

guide for making adjustments.

Stick Welding

Mid Sensitivity

MIG Welding

(short circuit)

Low-Mid Sensitivity

MIG Welding

(pulsed or spray)

Mid Sensitivity

TIG Welding

Mid-High Sensitivity

Plasma Cutting/

Welding

Low-Mid Sensitivity