Troubleshooting guide, Problem/cause remedy, Brewing problems – Grindmaster TEA-300 User Manual

Page 10

American Metal Ware

®

Tea Brewers

Page 9

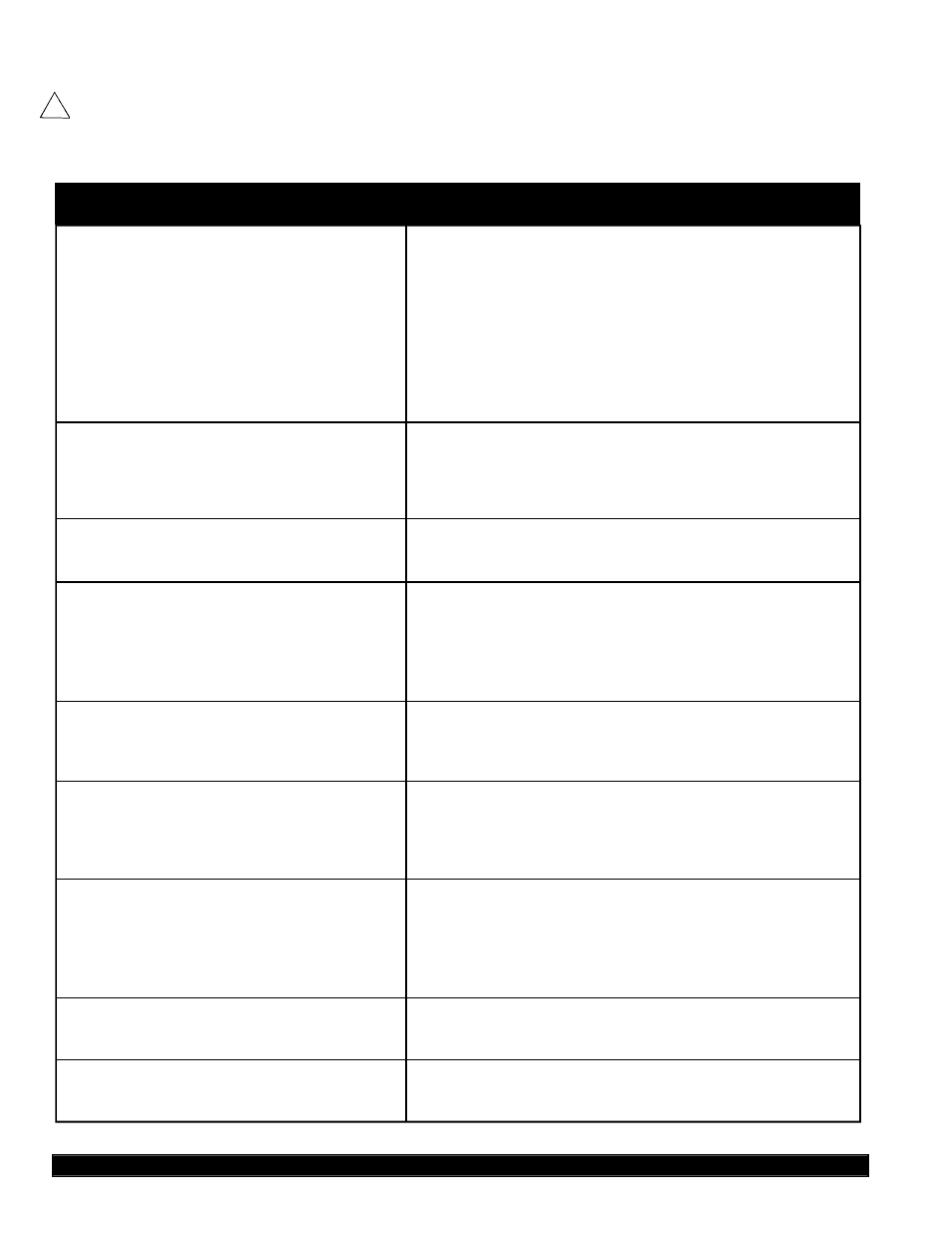

TROUBLESHOOTING GUIDE

Problem/Cause

Remedy

Weak tea

• Not enough tea used

• Water not hot enough

• Water not hot enough

• Sprayhead clogged

• Tea steeping time too short

• Use 1 oz. (28 g) tea per 1 gallon (3.8 litre) finished product

• Wait for Water Hot light to illuminate

• Check sprayhead temperature, should be greater than

185° F (85°C)

• Remove sprayhead for cleaning. Follow cleaning procedures

for sanitizing

• Water ratio of bypass to spray over not set properly, ideal

setting is 70 to 90 oz. (1960 to 2520 g) of hot water for

3 gallons (11.4 litres)

Strong tea

• Too much tea used

• Tea steeping time too short

• Use 1 oz. (28 g) tea per gallon (3.8 litre) finished product

• Water ratio of bypass to spray over not set properly, ideal

setting is 70 to 90 oz. (1960 to 2520 g) of hot water for

3 gallons (11.4 litres)

Grounds in tea

• Paper filter collapsed during brewing

• Using filter packs

• Use proper filter

• Add screen kit to brew basket

Brew basket overflowed

• Volume of hot water set too high

• Brew basket drain blocked

• Brew basket drain blocked

• Water ratio of bypass to spray over not set properly, ideal

setting is 70 to 90 oz. (1960 to 2520 g) of hot water for

3 gallons (11.4 litres)

• Paper filter collapsed during brewing

• Add screen kit to brew basket

Unpleasant taste

• Tea dispenser or brew basket needs cleaning

• Water tank has lime build-up

• Taste is coming from water supply

• Clean and sanitize

• De-lime water tank

• Install a water filtration system

Brew volume too large or too small

• Timer setting set too long or too short

• Water service not supplying adequate water

pressure or flow rate

• Adjust timer to desired value

• Water pressure measured at the unit’s water inlet valve

should be between 30 psi to 70 psi delivering a minimum of

1 gallon (3.8 litre) per minute

Brew volume erratic (small variations from

batch to batch are normal)

• Water supply pressure fluctuates

• Fill valve faulty or clogged

• Plumb water supply so that water pressure is not significantly

affected by other appliances

• Check for power at fill valve when unit is calling for water. If

water flow is slow or valve not operating then repair valve

Sprayhead will not stop dripping water

• Brew valve does not close completely

• Visually inspect valve. Clean lime from valve. Seat, cup, or

entire valve may need replacement

Water boiling in water tank

• Temperature in water tank too hot

• Reduce the water tank temperature. Adjustment knob is

located on the control board face

BREWING PROBLEMS

Only a qualified service technician should perform electrical and mechanical adjustments or

repairs. Always disconnect power before attempting any maintenance procedures.

!