Operations – Grizzly Extreme Series Jointer G9953ZX User Manual

Page 39

Extreme series Jointer (Mfg. since 9/11)

-37-

Operations

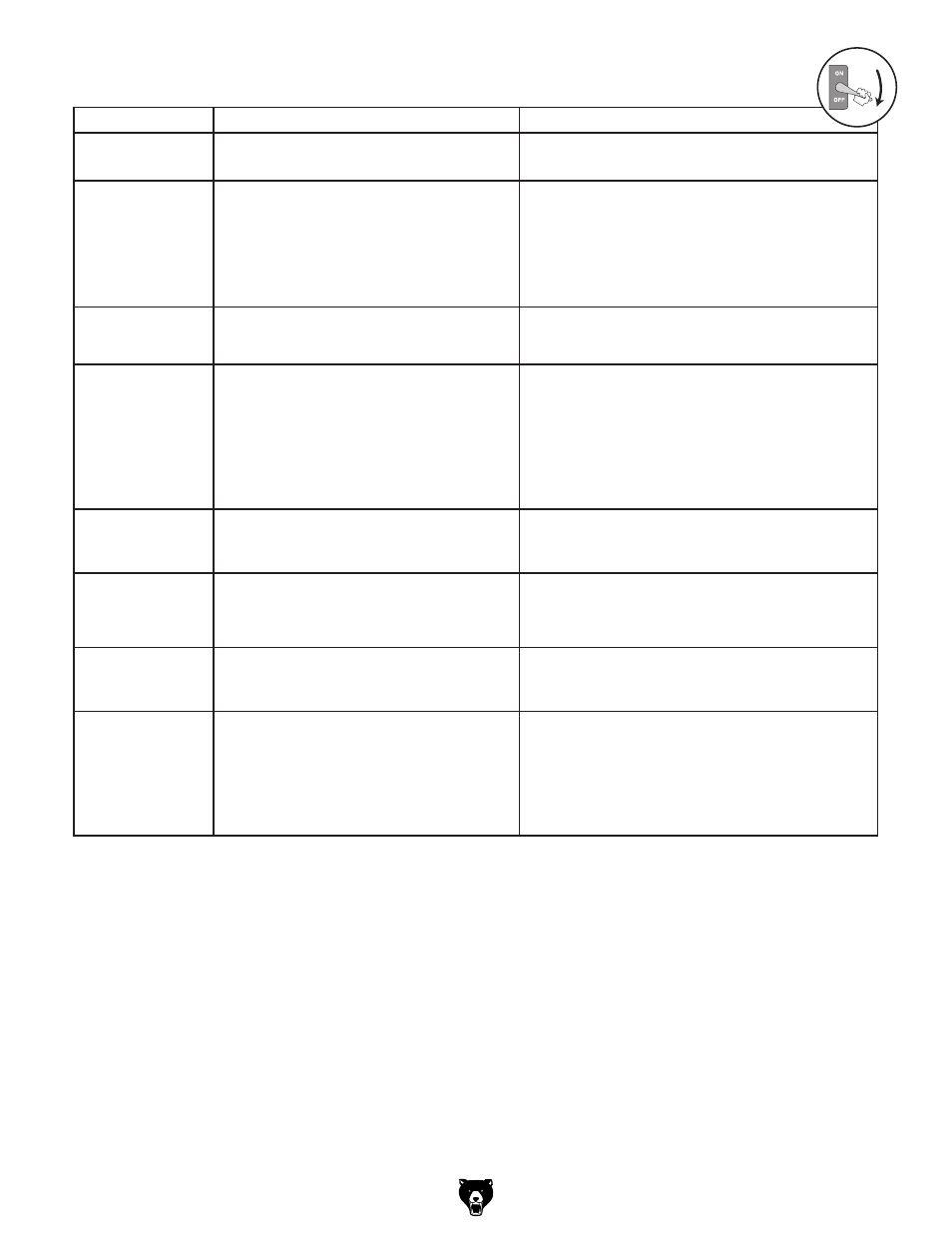

symptom

possible Cause

possible solution

tables are

hard to adjust.

1. table lock is engaged.

2. table stop bolts blocking movement.

1. loosen the table lock.

2. adjust table stop bolts (

page 46).

Excessive

snipe or

gouge in the

workpiece end

that is uneven

with the rest of

the cut.

1. outfeed table is set too low.

2. too much downward pressure on

workpiece end.

1. align outfeed table height with cutterhead tdC

(

page 44).

2. reduce downward pressure on that end of the

workpiece.

Workpiece

stops in the

middle of the cut.

1. outfeed table is set too high.

1. align outfeed table height with cutterhead tdC

(

page 44).

Chipping or

stuttering

patterns in

workpiece.

1. Knots or conflicting grain direction in stock.

2. Nicked or chipped knife or insert.

3. Feeding workpiece too fast.

4. depth of cut too much.

5. poor dust collection, chips not being

cleared from workpiece.

1. inspect workpiece for defects, cut with grain

(

page 26).

2. replace/rotate knives/inserts (

pages 38–39).

3. reduce feed rate.

4. reduce the depth of cut.

5. Check dust collection for proper operation;

clear blockages; reconfigure ducting system.

Fuzzy grain

left in workpiece.

1. Wood moisture too high.

2. dull knives or inserts.

1. stock moisture content should be less than

20%; sticker and let dry if necessary.

2. replace/rotate knives/inserts (

pages 38–39).

long lines or

ridges along

the length of

workpiece.

1. Nicked or chipped knife or insert.

2. loose or incorrectly installed insert.

1. replace/rotate knives/inserts (

pages 38–39).

2. remove/replace insert and install properly

(

page 38).

Wavy finish or

chatter marks.

1. Feed workpiece too fast.

2. Knives set unevenly.

1. reduce feed rate.

2. Check/adjust all knives for correct installation

and height (

page 39).

Workpiece

surface is

concave/

convex after

jointing.

1. Board not held with even pressure

during cut.

2. stock has excessive bow or warp.

3. insufficient number of passes.

1. Maintain even downward pressure on workpiece

during operation.

2. surface plane one face to use against the

jointer fence.

3. increase number of passes until the workpiece

face is flat.